|

|||

|

|

|||

|

Page Title:

Figure 3-5. Drive motor, disassembly and reassembly. |

|

||

| ||||||||||

|

|

TM 10-3930-611-35

1.

Screw (8 reqd)

29.

Screw (4 reqd)

2.

Washer, lock (8 reqd)

30.

Washer, lock (4 reqd)

3.

Bearing bracket, drive end

31.

Connector (short)

4.

Ball bearing, drive end

32.

Connector (long)

5.

Screw

33.

Connector, cross (2 reqd)

6.

Cover (half)

34.

Insulator (10 reqd)

7.

Cover (half) with nut

35.

Ball bearing, front end

8.

Screw (4 reqd)

36.

Pin cover (4 reqd)

9.

Washer, lock (4 reqd)

37.

Yoke and bearing support

10.

Nut (10 reqd)

38.

Nut, shaft

11.

Washer, lock (10 reqd)

39.

Armature (complete)

12.

Nut, hex (ref item #10)

40.

Key, commutator

13.

Washer, lock (ref item #11)

41.

Key, armature

14.

Washer, flat (10 reqd)

42.

Shaft

15.

Screw (5 reqd)

43.

Nut (ref item #10)

16.

Washer, flat (ref item #14)

44.

Washer, lock (ref item #11)

17.

Screw (8 reqd)

45.

Nut, hex (ref item #10)

18.

Washer, flat (8 reqd)

46.

Washer, lock (ref item #11)

20.

Holder, brush (4 reqd)

47.

Washer, flat (ref item #14)

21.

Washer, insulating (4 reqd)

48.

Washer, flat (ref item #14)

22.

Screw (8 reqd)

49.

Screw (ref item #15)

23.

Washer, lock (8 reqd)

50.

Insulator (ref item #34)

24.

Brush (4 reqd)

51.

Screw (8 reqd)

25.

Screw (ref item #22)

52.

Pole, main (4 reqd)

26.

Washer, lock (ref item #23)

53.

Coils, field (1 set reqd)

27.

Bracket, angle (4 reqd)

54.

Frame

28.

Spring (8 reqd)

Figure 3-5. Drive motor, disassembly and reassembly.

(2) Refer to figure 3-6 and remove the

contactors, SCR panel, fuse holders, terminal strips and

time delay relay.

b. Cleaning and Inspection.

(1) Wipe all parts with a clean, dry cloth.

(2) Inspect for breaks, cracks, corrosion,

loose or missing mounting hardware, elongated

mounting holes, or other defects.

(3) Tighten or replace loose or missing

mounting hardware, replace a damaged contactor, SCR

panel, terminal strip, fuse holder or time delay relay as

necessary.

c. Installation.

(1) Refer to figure 3-8 and install the

contactor, SCR panel, fuse holders, terminal strips and

time delay relay.

(2) Install the control box, (para 3-4).

3-7. Wiring Harness

whether run individually or in a harness, are marked or

numbered. The vast majority of the electrical leads

have crimp-on connections at each end; some of the

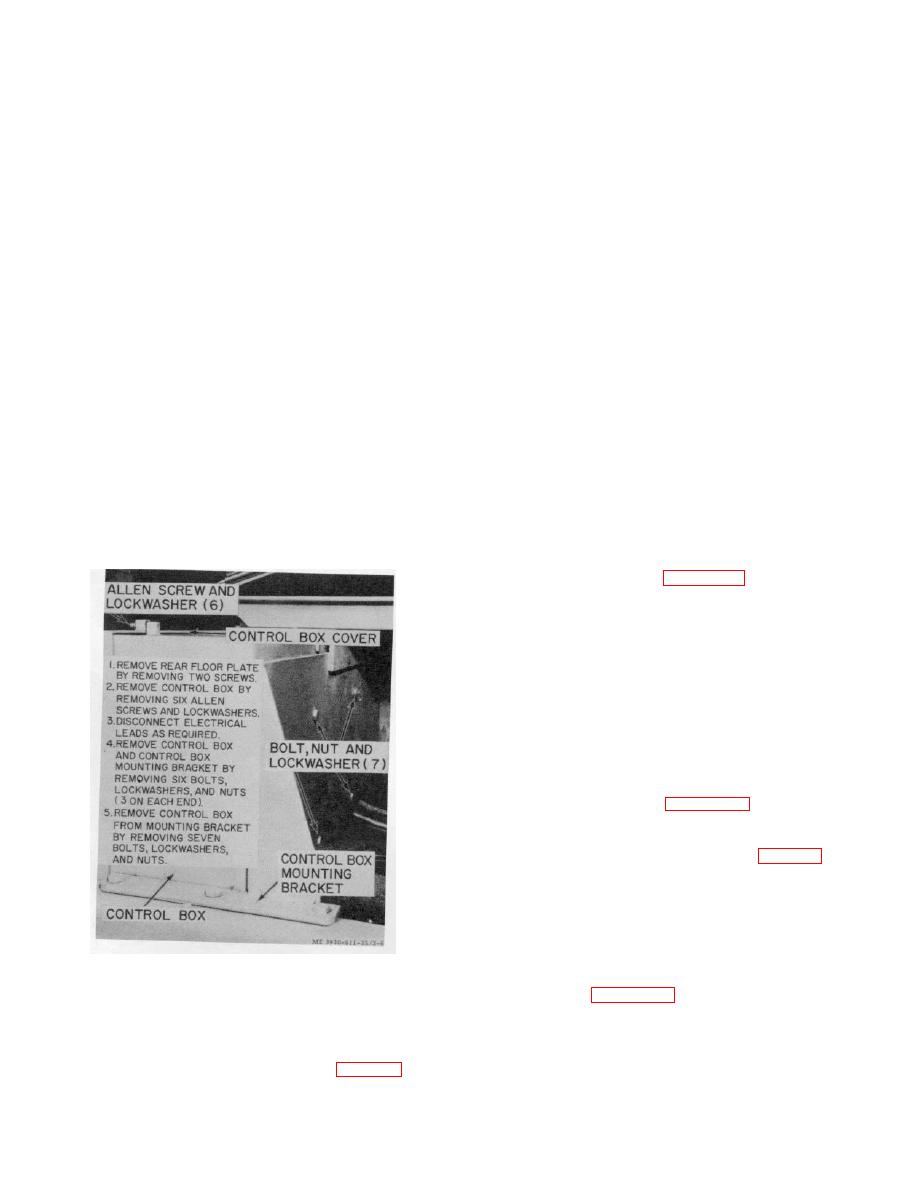

Figure 3-6. Control box, removal and installation.

components have quick disconnect type connectors on

the wire leads. Figure 3-6. Control box, removal and

installation.

3-6. Contractors, SCR Panel, Fuse Holders,

b. Inspection.

Inspect the insulation for

Terminal Strips and Time Delay Relay

cracks or frayed material. Pay particular attention to

a. Removal.

wires

(1) Remove the control box (para 3-4).

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |