|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ENGINE

5. Ream new valve stem guides to size given in

the Specification Listing, using a straight reamer ground

to correct size and having a pilot which will properly

locate it and keep it from wandering from the original

reamed hole.

CAUTION:

When replacing with guides that are

ferrox coated, do not ream since

these are all pre-reamed before being

ferrox coated. Further reaming will

remove the coating.

C. VALVE SEAT INSERTS

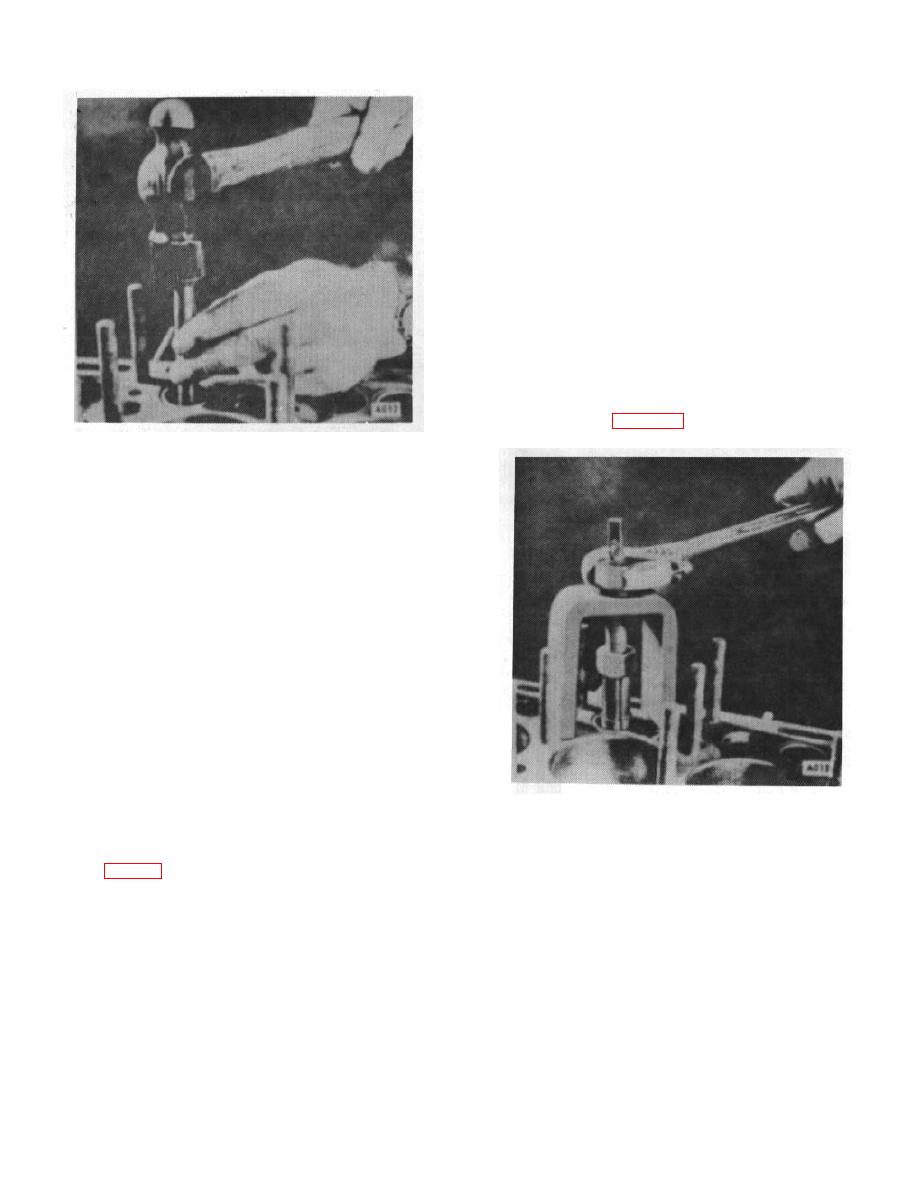

1. The exhaust valve seat insert is held in place by

a shrink fit. Inspect all exhaust valve seat inserts in the

block and replace any that are loose, cracked or

otherwise damaged. Use a puller for removing a faulty

insert as shown in Figure 12. When replace

Figure 71.

remove the keepers from these valves in the same

manner. Remove all valves and place in correct order

to prevent mixing while handling.

B. VALVE GUIDES

1. Clean the valve stem guides, removing lacquer

or other deposits by running a valve guide cleaner or

wire brush through the guides.

2. Check guides for wear by using a "go and no-

go" plug gauge or a telescope gauge and 1" micrometer.

Replace all guides that are worn bellmouthed and have

increased .0015" in diameter, See Specification Listing

for maximum diameter permissible to determine actual

amount the diameter has increased.

3. Remove all valve guides when necessary by

Figure 12.

driving them out from the combustion chamber side with

a driver slightly smaller than the O.D. of the valve

ment of a new insert is required, clean and counterbore

guide. (Fig. 11)

for .010" larger insert using a counterbore tool with a

correct fitting pilot. When machining the counterbore,

be sure to go deep enough with the tool to clean up the

4. Install new guides as required by driving from

bottom so that the insert will have full contact to carry

the combustion side to the correct depth below the valve

away the heat. Do not install new inserts having the

seat as given in the Specification Listing.

same outside diameter as

B-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |