|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

ENGINE

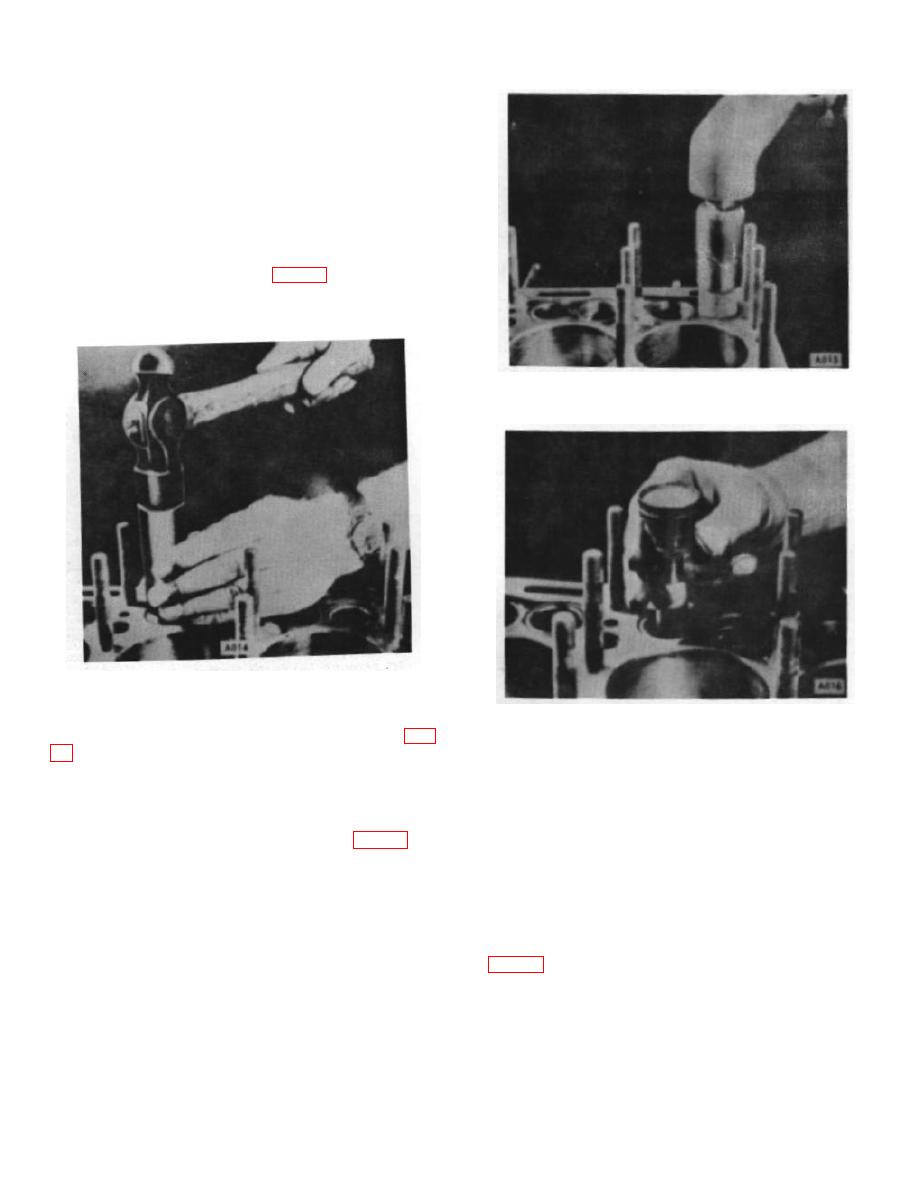

the one removed. Dimensions of standard inserts and

counterbores are given in the Specification Listing.

2. When oversize inserts are used, dimensions of

the insert and counterbore increase proportionately

(.010", .020", .030", depending on the oversize). New

insert installation should have a press fit. Chill insert

with dry ice for 20 minutes before assembling. Insert

may then be installed in the counterbore using a piloted

driver, tapping in place with very light hammer blows,

without shearing the side walls. (Fig. 13) This assures a

firm seating in the bottom of the counterbore, after

which it should be rolled in place.

Figure 14.

Figure 13.

Figure 15.

3. Grind the intake and exhaust valve seats (Fig.

D. VALVES

Before removing the arbor, check seat for runout. Total

indicator reading of the run-out must not be more than

1. Inspect valves and replace any that are

.002". Use a solid stem pilot with a long taper, as all

cracked, burned or which have stems that are bent or

valve seats must be ground concentric and square with

worn more than .002" over the maximum allowable

either new or worn valve stem guide holes. (Fig. 15)

limits. Reface or replace all valves.

2. All valves having less than 50% margin

thickness (outer edge of valve head) after refacing has

been completed, should be replaced. To check this

dimension, compare the refaced valve with a new valve.

B-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |