|

|||

|

|

|||

|

Page Title:

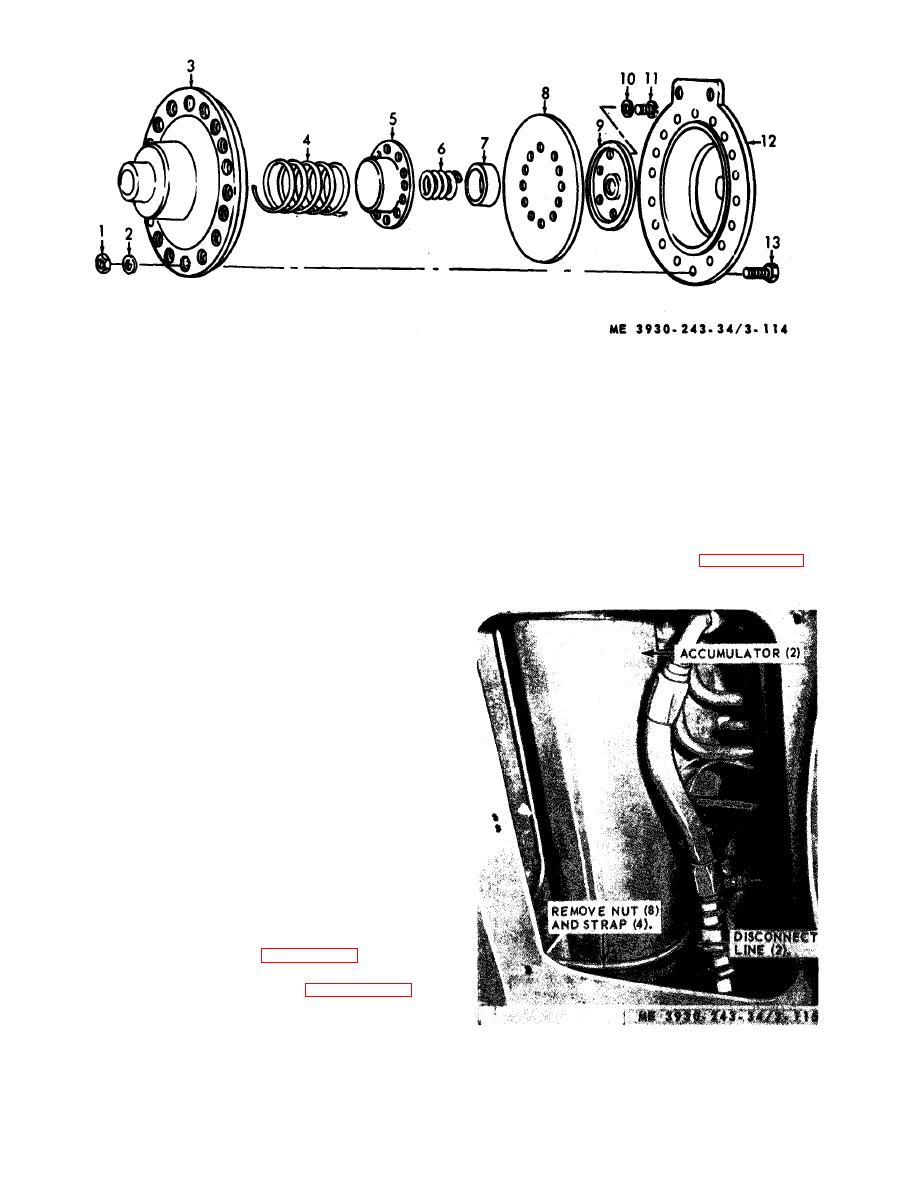

Figure 3-114. Automatic slack adjuster, disassembly and reassembly. |

|

||

| ||||||||||

|

|

8

Diaphragm

1

Nut

9

Piston

2

Washer

10

Washer

3

Housing

11

Bolt

4

Spring

12

Cap

5

Piston

13

Bolt

6

Spring

7

Piston

(2) Inspect piston for scores and scratches.

(3) Inspect body for cracks or any damage.

a. General. The accumulator is provided to store

Replace a defective part.

e n e r g y for a limited number of brake applications

e . R e a s s e m b l y . Refer to figure 3-116 and

i n case the engine stops running. The accumulator

reassemble hydraulic brake accumulator.

cylinder has a free riding piston. Nitrogen is in-

troduced through a valve on one end of cylinder

and at the opposite end of cylinder, oil from the

h y d r a u l i c system enters cylinder forcing the piston

toward the nitrogen, compressing it to ap-

p r o x i m a t e l y 1,300 psi. The accumulator is located

behing the operator's access ladder panel.

WARNING

B l e e d the brake system pressure by

repeated application of the brakes with

t h e e n g i n e stopped, u n t i l t h e l o w

pressure warning buzzer sounds.

Continue to apply brakes several times

to further reduce accumulator pressure.

C a r e f u l l y open bleed valves at each

a u t o m a t i c slack adjuster to bleed off

pressure. F a i l u r e t o b l e e d p r e s s u r e

from brake system before servicing or

p e r f o r m i n g maintenance function may

result in damage to equipment and

s e r i o u s injury to personnel.

the hydraulic brake accumulator.

disassemble the hydraulic brake accumulator.

d. Inspection.

(1) Inspect tubing and connectors for cracks or

damage.

accumulators, removal and installation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |