|

|||

|

|

|||

|

Page Title:

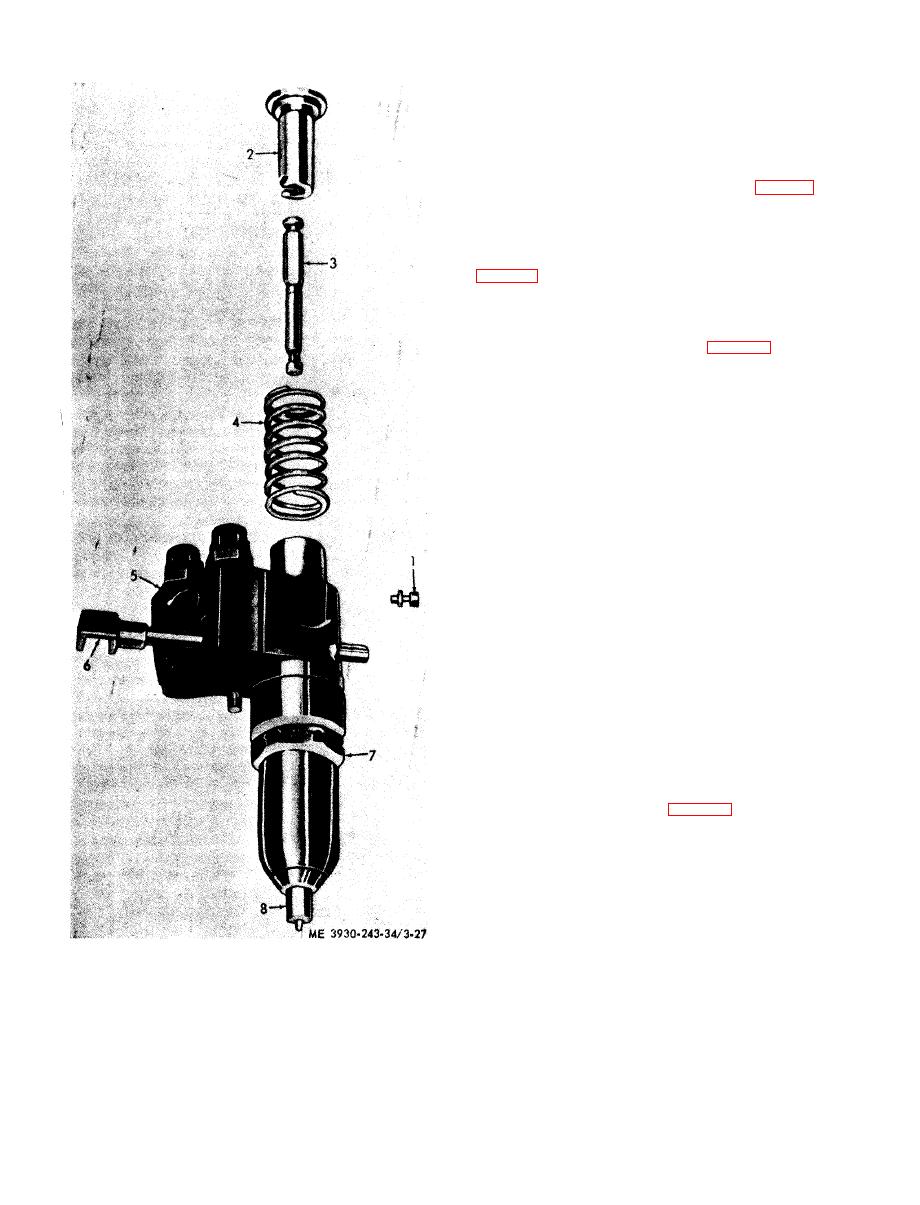

Figure 3-27. Injector follower, spring and plunger, removal and installation |

|

||

| ||||||||||

|

|

e. Cleaning and Inspection. Since most injector

difficulties are the result of dirt particles, it is

essential that a clean area be provided on which to

place injector parts after cleaning and inspection.

(1) Clean out all passages, drilled holes and

slots in the injector.

(2) Clean the spray tip with reamer (fig. 3-28).

Turn reamer in a clockwise direction to remove

carbon deposits.

(3) Clean the spray tip orifices with pin vise

tool using the proper size spray tip cleaning wire

holes.

(4) Clean and brush all passages in injector

body. Carefully insert reamer into the injector nut

and ream injector spray tip seat (fig. 3-30). Turn

reamer in a clockwise direction to remove carbon

deposits.

(5) Inspect the teeth on the control rack and

control rack gear for wear and damage. Inspect

both ends of spill deflector for sharp edges or burrs.

Remove burrs with a medium stone.

(6) Inspect follower spring for defects and

proper tension. The spring has a free length of

approximately 1.504 inches. Replace spring when

load of less than 70 pounds will compress it to

1.028 inch.

(7) Check seal ring area in the injector body

and surface which contacts the injector bushing for

damage. If necessary lap this area.

(8) Inspect the injector plunger for scoring,

erosion chipping or wear. Check for sharp edges on

portion of plunger which rides in the gear. Remove

any sharp edges with a 500 grit stone and clean.

Slip the plunger into the bushing and check for free

movement. R e p l a c e w o r n , c h i p p e d , o r s c o r e d

plungers and bushings as an assembly since they

are mated parts.

( 9 ) Excessive spray tip seating surface of

injector nut for nicks, burrs, or brinelling.

(10) Inspect the sealing surfaces of injector

parts as indicated by arrows (fig. 3-31). Inspect all

surfaces with a magnifying glass, for even the

slightest imperfection will prevent injector from

operating properly. Check for burrs, nicks, erosion,

cracks, chipping, and excessive wear. Inspect spray

tips for enlarged orifices.

5 Body

1 Stop pin

6 Control rack

2 Follower

7 Nut

3 Plunger

8 Spray tip

4 Follower spring

and installation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |