|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(4) Add or remove shims at regulators A, B, C, and

(2) With control in neutral and engine running at

600 rpm, check transmission oil level. Fill as

D to increase or decrease pressure readings at

check ports 1, 2, 3, and 4. Add shims to

necessary.

(3) Adjust pressures to the limits as shown in the

increase pre. sure; remove shims to decrease

pressure.

" ransmission Pressure Settings"below.

T

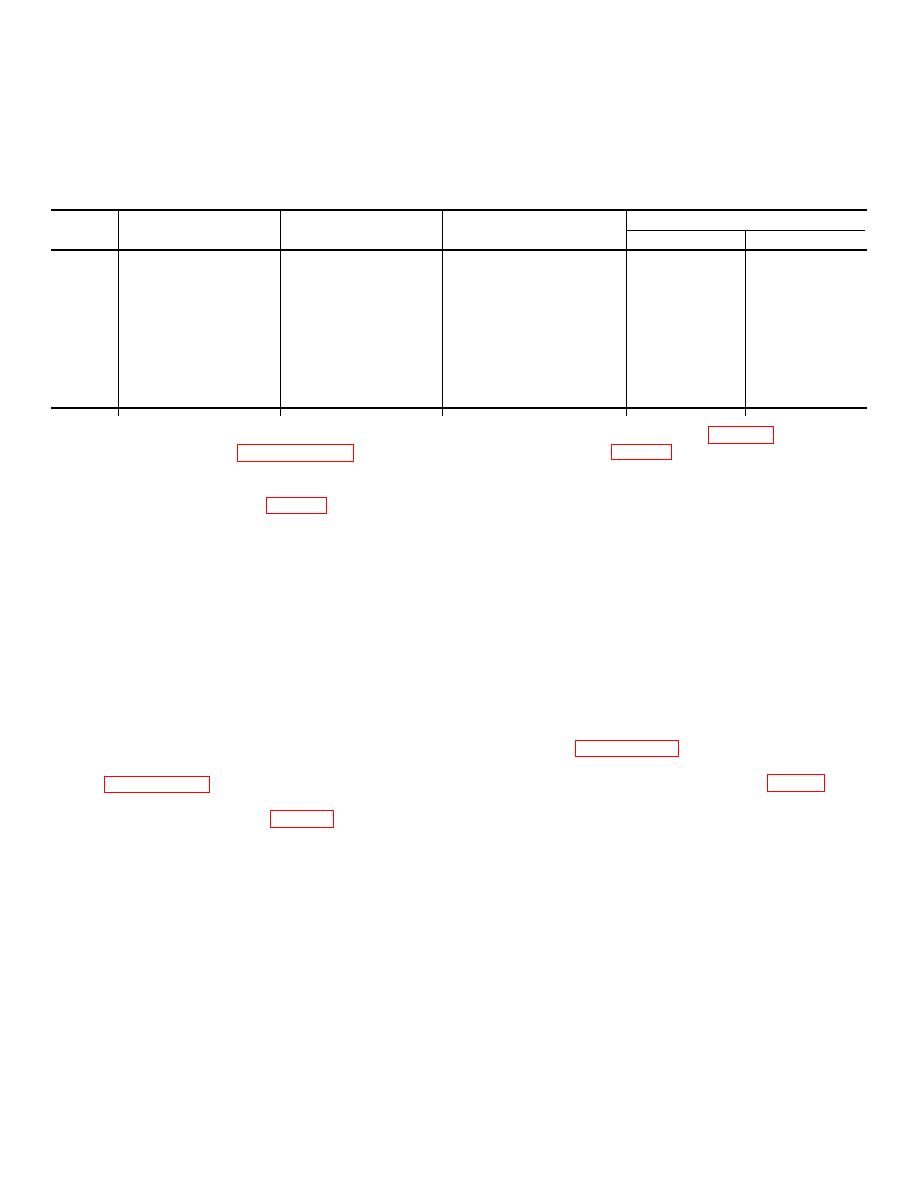

Transmission Pressure Settings

Check

Range

port

Regulator

Set to

Control position

600 rpm

2,400 rpm

1

A

130 to 140 psi

Neutral

110 psi

150 psi

Pump and Hi-Lo

at 1,500 rpm

2

B

85 to 95 psi

Neutral

30-85 psi

150 psi

Forward and Reverse

at 1,500 rpm

3

C

70-75 psi

Neutral

5-55 psi

75 psi

Converter In

at 2,400 rpm

4

D

Neutral

2 psi

45 psi

Converter Out

(4) Remove place bolts (14, fig. 32) and retainer

39. Ring Gear Assembly

plate (13, fig. 17). Separate cover (12) from

a. Removal.

Refer to paragraph 38b, steps (1)

cage assembly (3).

through (3).

(5) Remove gear (10) from cage assembly.

b. Disassembly.

(6) Remove thrust washers (9 and 11) from gear

(1) Remove snap ring (22, fig. 32) from ring gear

(10).

assembly (30).

(7) Remove pinion shafts (5), thrust washers (4 and

(2) Slide front cover (25) from gear assembly.

8), and pinion sets (6 and 7) from cage

(3) Remove snap ring (28) that retains bearing (29)

assembly.

to ring gear assembly shaft.

Note. The 18-tooth pinion set (6) meshes

(4) Using bearing puller remove bearing from shaft.

with the sun gear (10). The 19-tooth pinion set

(5) Remove needle bearing from shaft housing if

(7) measure with the ring gear assembly (30).

necessary.

c. Assembly.

Reverse procedures in b above.

c. Assembly. Reverse the procedures in b above.

Lubricate all parts before assembly.

d. Installation. Reverse the procedures in a above.

d. Installation. Reverse procedures in a above.

40. Planetary Carriage Assembly

41. Forward-and-Reverse Clutch Assembly

a. Removal.

a. Removal. Follow the procedures in steps (7)

(1) Remove transmission (par. 38a).

through (14), paragraph 38a.

(2) Remove planetary carriage assembly by

b. Disassembly.

following procedure in steps (1) through (4),

(1) Remove ring seals (11 and 12, fig. 40) from

forward drive shaft assembly (9).

b. Disassembly.

(2) Remove capscrews (21) that secure clutch

(1) Remove thrust washer (fig. 84) from carriage

assembly together.

assembly.

Caution: The clutch pack assembly will

(2) Remove safety wires that secure place bolts.

fall apart when removing the capscrews (21),

(3) Mark the cage Assembly and cover before

disassembly.

due to spring tension inside the pack, if care

is not exercised in removing capscrews.

AGO 7010A

38

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |