|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

16

This Task Covers:

a. Disassembly

c. Inspection

b. Cleaning

d. Assembly

INITIAL SETUP

Materials/Parts (Cont)

Tools and Special Tools

Solvent, Dry Cleaning P-D-680

Tool Kit, General Mechanic's: Automotive

(Item 52, Appendix B)

(Item 23, Appendix D)

Container, 5 gal (19 l) capacity

Wrench Set, Spanner (Item 26, Appendix D)

Nut

Packing, Preformed

Equipment Condition

Packing, Preformed

Frame tilt cylinder removed (TM 10-3930-673-20)

Packing, Preformed

Materials/Parts

Packing, Preformed

Compound, Sealing (Item 42, Appendix B)

Packing, Preformed

Oil, Lubricating, Transmission/Hydraulic

Seal

(Item 30, Appendix B)

Rags, Lint-free (Item 34, Appendix B)

Personnel Required

Two

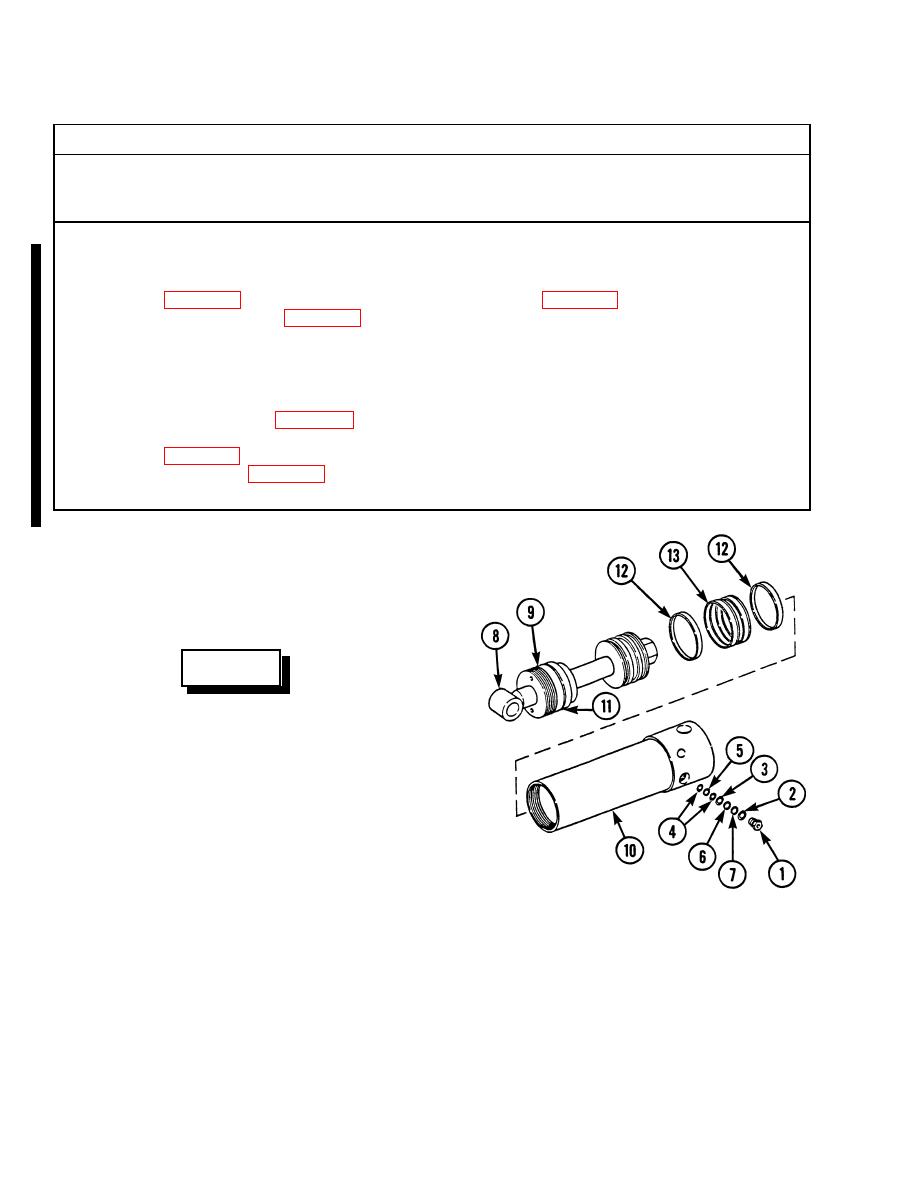

a. Disassembly.

(1)

Use a vise with soft jaws to secure frame tilt

cylinder in a horizontal position for

disassembly.

WARNING

Hydraulic oil, under pressure, can remain

within cylinder after disconnecting

hydraulic hoses. To avoid severe personal

injury, slowly loosen counterbalance

valve and allow pressure to escape before

removing valve entirely.

NOTE

Note and mark location of counterbalance

valves for use during assembly.

TR01013

Counterbalance valves are not

interchangeable.

(2)

Relieve pressure in frame tilt cylinder by slowly removing two counterbalance valves (1). Drain residual oil

through valve holes into a suitable container.

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |