|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

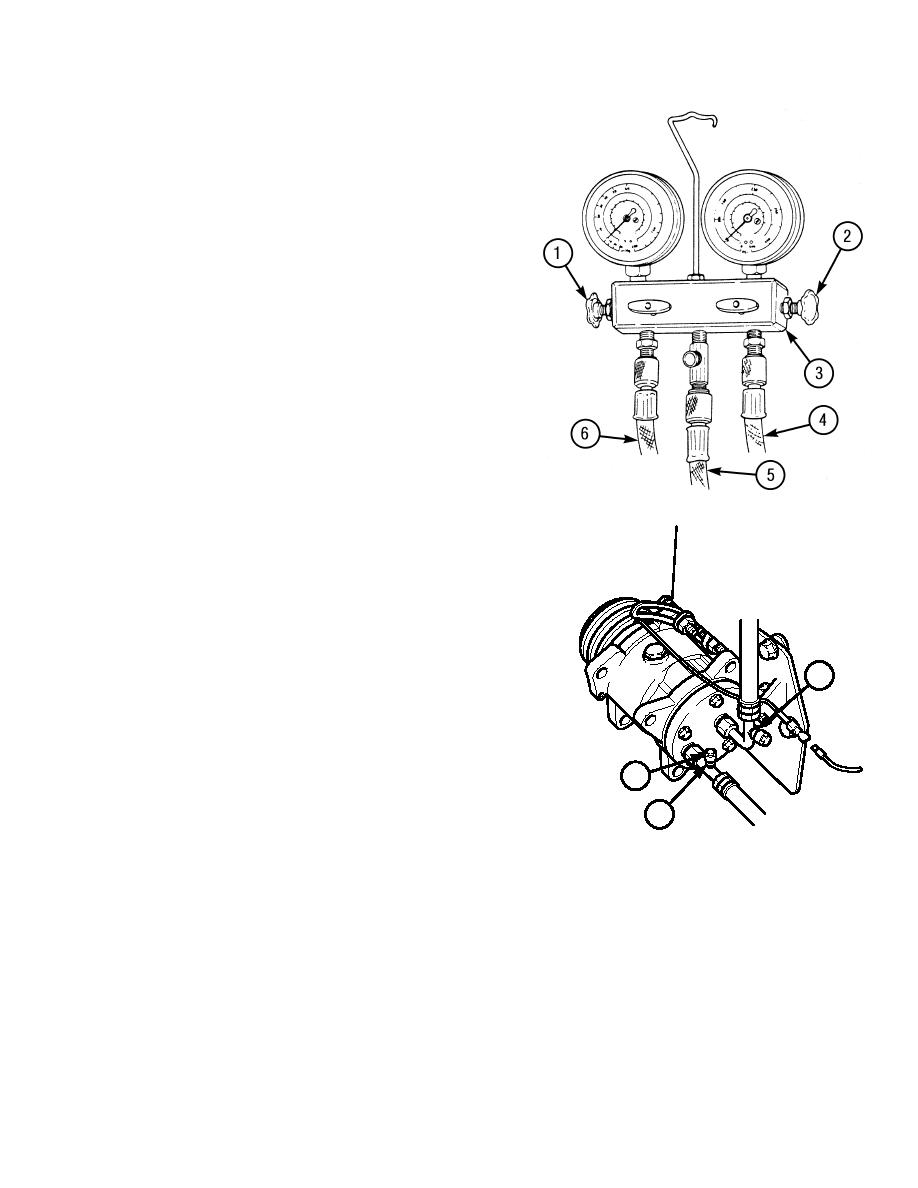

b. Manifold Gage Set Removal.

(1)

Loosen low pressure gage valve (1) and

high pressure gage valve (2) slowly,

allowing refrigerant to escape from

hoses (4) and (6) through hose (5).

(2)

Disconnect low pressure gage hose (5)

and high pressure gage hose (4) from

service valve ports (7) and (8).

(3)

Install two dust caps (9) on service valve

ports (7) and (8).

c. Discharging System.

(1)

Disconnect negative battery cable

(TM 10-3930-673-20).

(2)

Install manifold gage set (refer to task a.).

(3)

Insert center hose (5) of manifold gage

set (3) in a catch bottle or can.

NOTE

Do not allow refrigerant R-134 to

escape too quickly. Refrigerant oil

will escape.

When high pressure gage and low

pressure gage read "zero", the

8

discharging procedure is

complete.

(4)

Turn low pressure gage valve (1) and

high pressure gage valve (2)

9

counterclockwise slightly to permit

refrigerant to slowly escape through

7

center hose (5) until gages read "zero".

(5)

Measure any significant accumulation of

oil in discharge bottle and record for oil charging purposes.

(6)

Disconnect manifold gage set (refer to task b.).

15-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |