|

|||

|

|

|||

|

Page Title:

REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

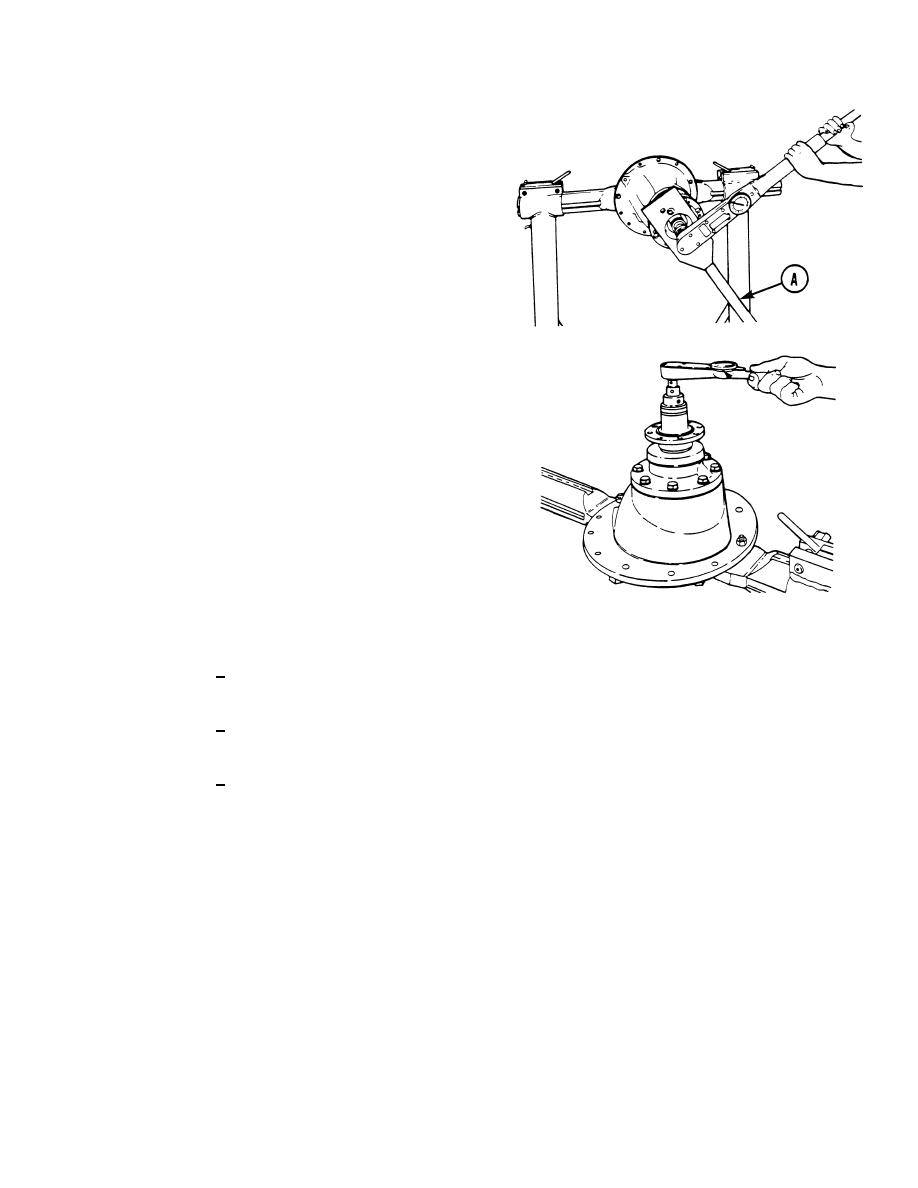

(d)

Fasten fabricated yoke nut tool to

companion yoke (9). Use fabricated

yoke nut tool (A) to hold bevel

pinion (29) in position when nut (31)

is tightened.

(e)

Tighten nut (31) on bevel pinion (29)

to 300 - 400 lb-ft

(406.75 - 542.33 Nm).

(f)

Remove bar from companion

yoke (9).

NOTE

Do not read starting torque. Read

only torque value after bevel pinion

starts to rotate. Starting torque will

give a false reading.

(g)

Attach torque wrench on bevel

pinion nut (31). Rotate bevel

pinion (29) and read value indicated

on torque wrench. New pinion

bearings should be preloaded

between 5 - 45 lb-in. (0.56 - 5.08

Nm) of torque. Reused pinion

bearings should be preloaded

TR00438

between 10 - 30 lb-in. (1.13 - 3.39

Nm).

Increase bearing preload by removing bevel pinion (29) from bearing cage (30) and

1

installing a thinner bearing spacer (40). Repeat Steps (a) through (g).

Decrease bearing preload by removing bevel pinion (29) from bearing cage (30) and

2

installing a thicker bearing spacer (40). Repeat Steps (a) through (g).

Remove nut (31), washer (32), and companion yoke (9) from bevel pinion (29).

3

(h)

Remove eight screws (33) from bearing cage (30).

(i)

Remove bevel pinion (29) and bearing cage (30), as an assembly, from differential carrier (3).

(3)

Install pinion oil seal (36).

(a)

Apply thin film of gear lubricant to inner surface of bevel pinion oil seal (36).

(b)

Apply thin film of gear lubricant to seal bore in bearing cage (30).

(c)

Use a press or mallet and suitable sleeve to install bevel pinion bearing oil seal (36) in bearing

cage (30) until flange of seal is against bearing cage.

9-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |