|

|||

|

|

|||

|

Page Title:

REAR DIFFERENTIAL CARRIER ASSEMBLY REPLACEMENT/REPAIR/ ADJUSTMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

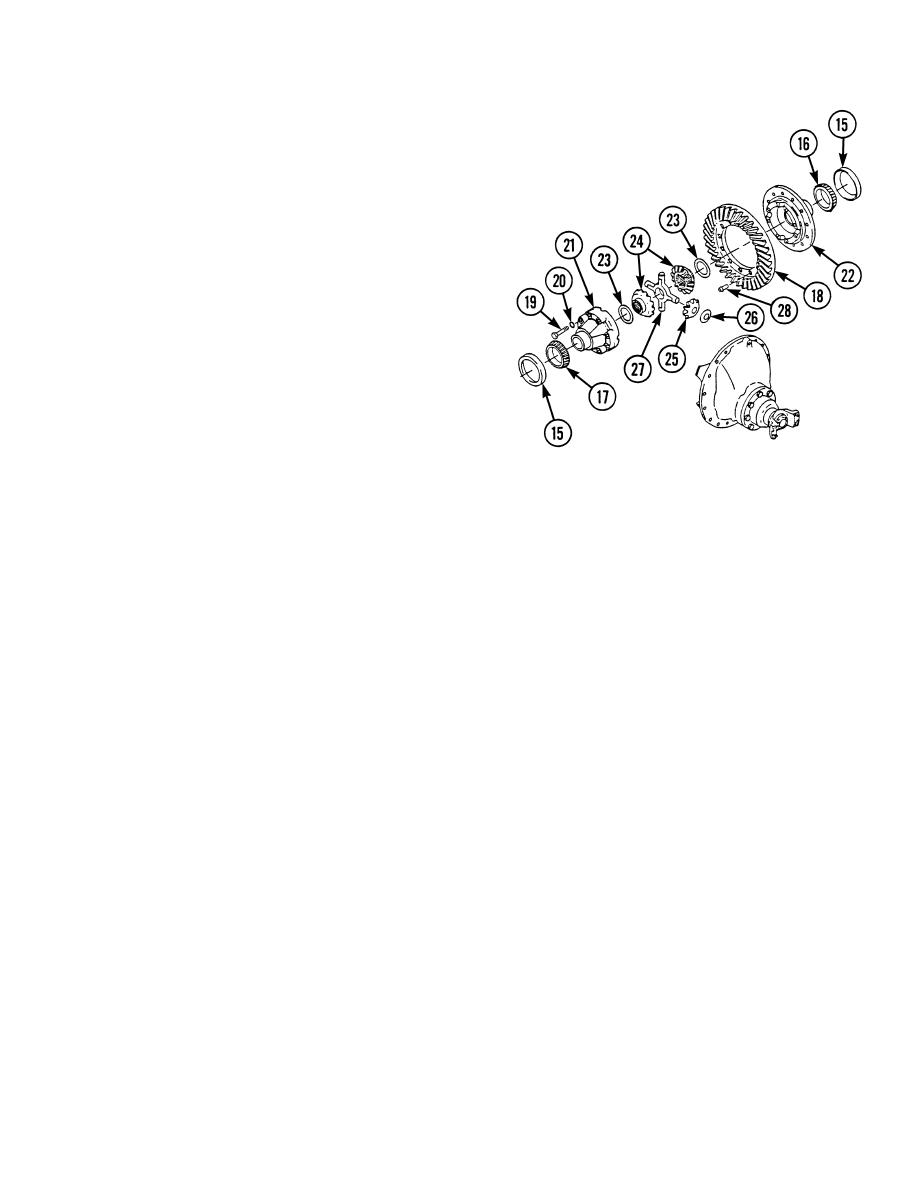

(e)

Use sling to lift differential and ring

gear assembly from the carrier.

Place assembly on a work bench.

(f)

Remove two bearing cups (15) from

flange case half bearing cone (16)

and plain case half bearing

cone (17).

(g)

Using suitable puller, remove flange

case half bearing cone (16) and plain

case half bearing cone (17).

(2)

Disassemble differential and ring

gear (18).

(a)

Mark each case half for ease of

assembly.

(b)

Remove eight screws (19) and

TR00434

washers (20) from plain case

half (21).

(c)

Separate case halves (21 and 22).

(d)

Remove two side gear thrust washers (23), two side gears (24), four pinion gears (25), pinion

gear thrust washers (26), and differential spider (27).

(3)

Remove ring gear (18).

(a)

Inspect ring gear (18) for wear or damage. If ring gear needs replacement, center punch 12

rivets (28) on side of ring gear.

(b)

Drill 12 rivets (28) on ring gear (18) to a depth equal to thickness of one rivet head. Use a drill

bit 1/32 in. (0.031 mm) smaller than rivet body diameter.

(c)

Press or drive 12 rivets (28) from drilled side through holes in ring gear (18) and flange case

half (22). Discard rivets.

(d)

Support assembly under ring gear (18) with blocks and use suitable press to remove case

half (22) through ring gear.

9-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |