|

|||

|

|

|||

|

Page Title:

Section II. FRONT AXLE MAINTENANCE PROCEDURES |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

8

Section II. FRONT AXLE MAINTENANCE PROCEDURES

This Task Covers:

a. Removal

c. Cleaning

e. Assembly

b. Disassembly

d. Inspection

f. Installation

INITIAL SETUP

Materials/Parts

Tools and Special Tools

Compound, Sealing (Item 14, Appendix B)

Tool Kit, General Mechanic's: Automotive

Oil, Lubricating, Gear (Item 29, Appendix B)

(Item 23, Appendix D)

Rags, Lint-free (Item 34, Appendix B)

Shop Equipment, Automotive Maintenance,

Tags (Item 55, Appendix B)

Common No. 2 Less Power

Locknut

(Item 17, Appendix D)

Lockwasher

Shop Equipment, Automotive maintenance and

Wood Blocks, 3 in. (76.2 mm)

Repair; Field Maintenance, Basic, Less Power

Container, 5 gal (18.93 l) capacity

(Item 18, Appendix D)

Steel Bar (minimum 1 in. [25.4 mm] diameter

Cap and Plug Set (Item 1, Appendix D)

and 6 ft [1.83 m] long)

Floor Jack, 10 ton (9071.84 kg) capacity

Jackstands (2) 40 in. (101.6 cm) height,

Personnel Required

3-1/2 ton (3175.14 kg) capacity

Two

Equipment Condition

Vehicle parked on level surface.

Parking brake set.

Rear wheels chocked.

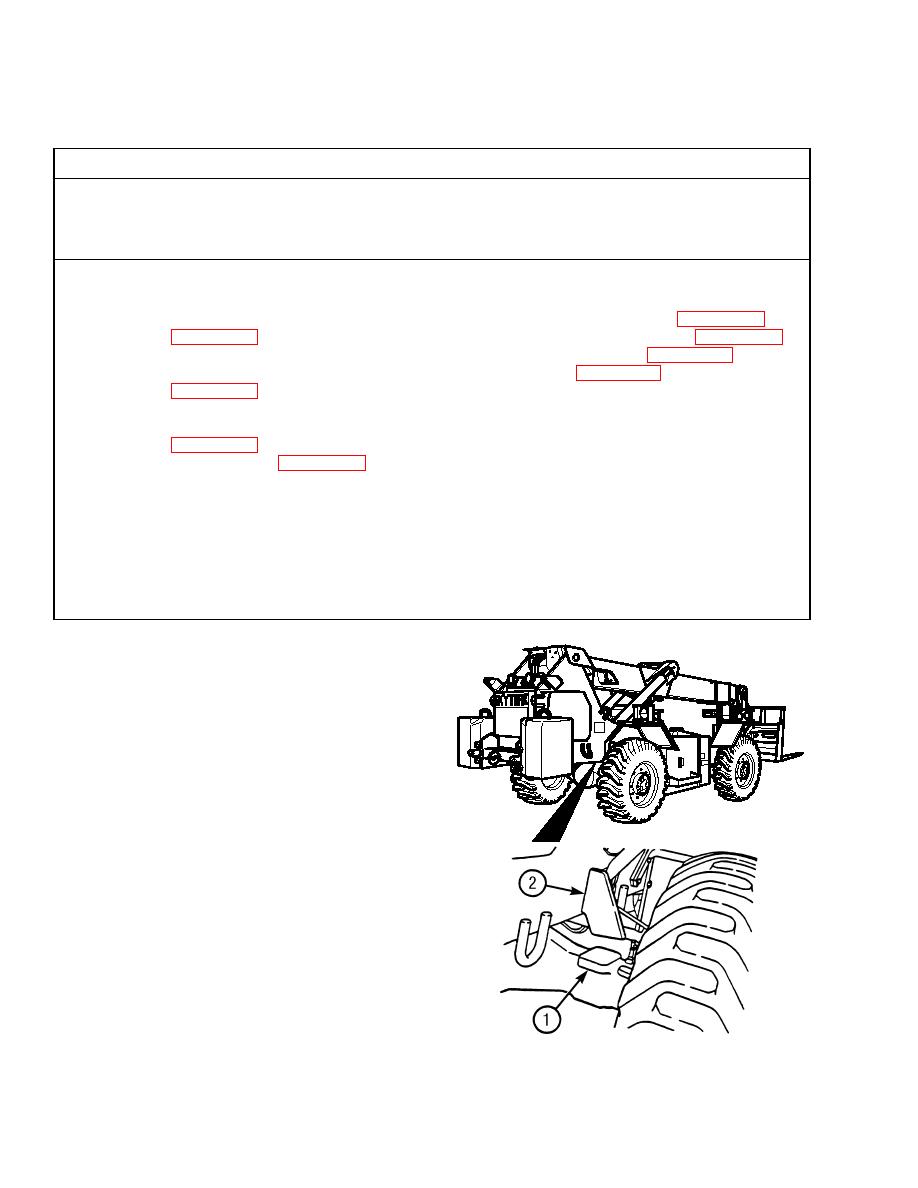

a. Removal.

(1)

Place wood blocks (3 in. [76.2 mm]

thick) between frame pads (1) on

rear axle and frame tilt stop pads (2).

This will prevent frame from tilting

when removing front tilt cylinders.

(2)

Start engine and raise boom for

sufficient work clearance

TR00001

(TM 10-3930-673-10).

(3)

Disconnect parking brake cable

(TM 10-3930-673-20).

(4)

Remove front propeller shaft

(TM 10-3930-673-20).

(5)

Raise front of vehicle 8 in. (203.2

mm) off ground and support under

frame (TM 10-3930-673-20).

(6)

Remove frame tilt cylinder

TR00249

(TM 10-3930-673-20).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |