|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

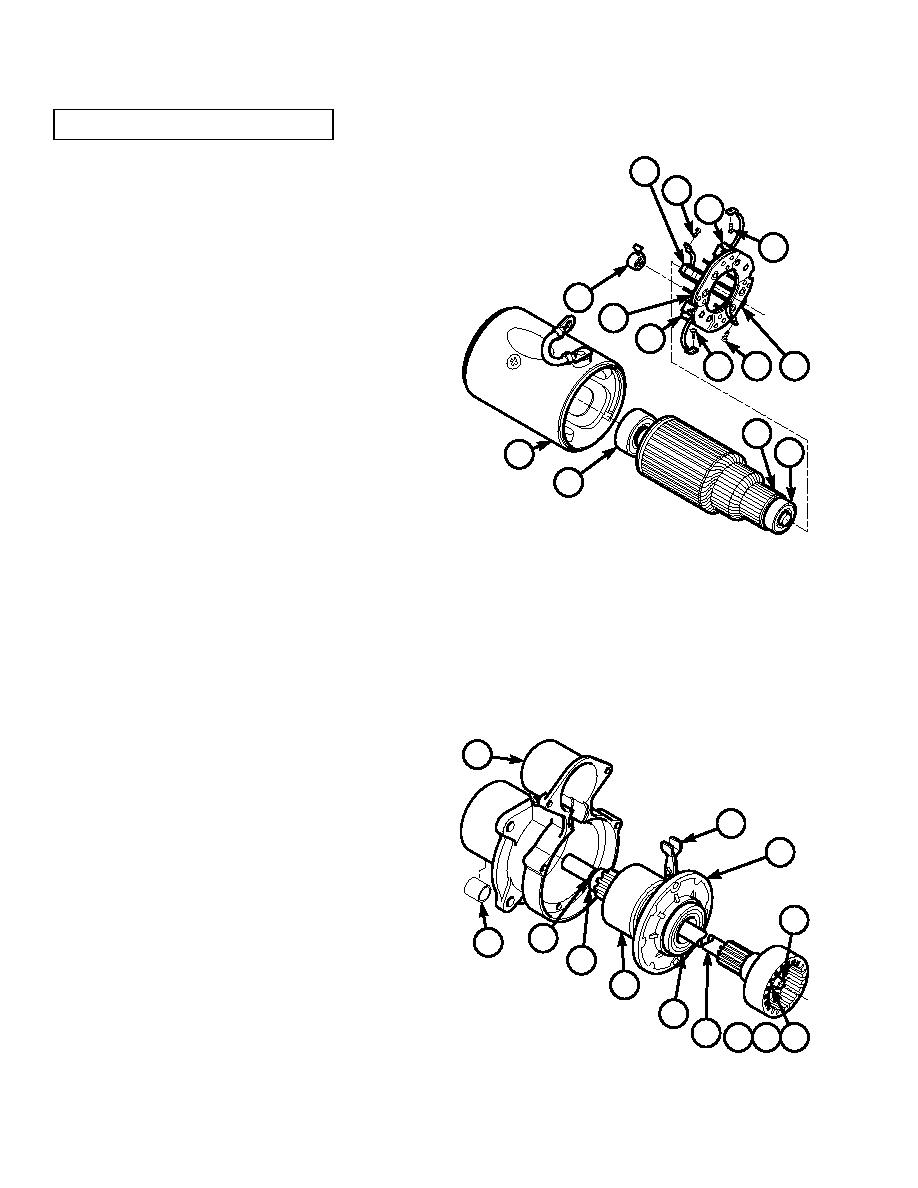

6-4. STARTER REPAIR (CONT)

(4)

Check for short circuits in armature (13)

14

using a growler and steel strip.

19

15

(a)

Rotate armature (13) in growler.

18

(b)

Hold steel strip (e.g., hacksaw blade)

across armature slots as armature

rotates. Steel strip will vibrate as slot

21

between shorted bars passes under steel

20

strip.

15

(c)

If short circuit is detected, check for build

19

14

18

up of copper dust or other conductive

material between commutator bars.

Clean out copper dust and check again for

short circuits. If commutator bars are

13

shorted, replace armature (13).

16

9

(5)

Check armature for grounds or open

17

circuits.

(a)

Set multimeter to ohms, on highest scale.

Check for grounds by measuring resistance between commutator and one armature bar.

(b)

Switch multimeter to lowest scale.

(c)

Place multimeter leads against two adjacent commutator bars and observe multimeter.

Multimeter needle should swing to zero and remain.

(d)

Repeat check for all commutator bars by moving one multimeter lead at a time. There must be

continuity between each pair of bars. If there is no continuity between one or more pairs of

bars, replace armature (13).

d. Assembly.

22

(1)

If removed, install bushing (40) in

drive housing (22).

27

(2)

Install bearing (39) on drive

shaft (30).

31

(3)

Position shaft support (31) and drive

clutch assembly (32) on drive

36

shaft (30).

38

40

37

32

39

30

33 34 35

TR01410

6-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |