|

|||

|

|

|||

|

Page Title:

Section II. ELECTRICAL SYSTEM MAINTENANCE PROCEDURES |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

Section II. ELECTRICAL SYSTEM MAINTENANCE PROCEDURES

6

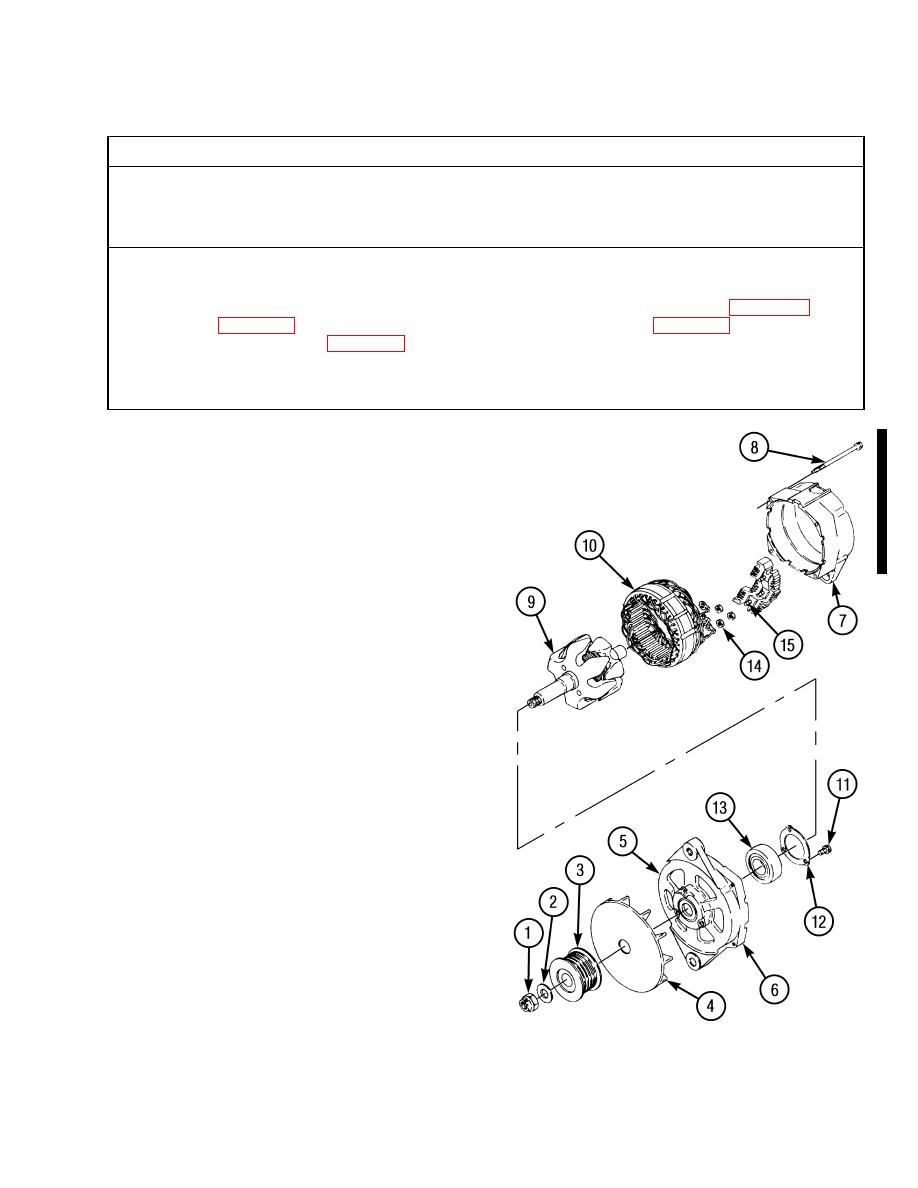

6-3. ALTERNATOR REPAIR/TEST

This Task Covers:

a. Disassembly

c. Inspection

e. Assembly

b. Cleaning

d. Testing

INITIAL SETUP

Materials/Parts

Tools and Special Tools

Lubricant, Delco-Remy (Item 21, Appendix B)

Tool Kit, General Mechanic's: Automotive

Sandpaper (Item 37, Appendix B)

(Item 23, Appendix D)

Bearing Cap

Multimeter, Digital (Item 14, Appendix D)

Bushings (2)

Locknut

Equipment Condition

Alternator removed (TM 10-3930-673-20)

NOTE

Alternator is one of two different models

used on ATLAS vehicles. Although

configuration of a few components

between models is slightly different,

many are identical. This paragraph can be

used to repair/test either alternator.

a. Disassembly.

(1)

Remove locknut (1), washer (2), pulley (3),

and fan (4) from alternator (5). Discard

locknut.

(2)

Separate front frame (6) from rear frame (7).

(a)

Remove four screws (8) from alternator

(5).

(b)

Separate front frame (6) and rotor

assembly (9) from rear frame (7) and

stator assembly (10).

(3)

Remove rotor assembly (9) from front frame

(6).

(a)

Use suitable press to remove bearing (13)

in front frame (6) from rotor assembly

(9).

(b)

Remove three screws (11), retainer plate

(12), and roller bearing (13) from front

frame (6).

(4)

Remove stator assembly (10) from rear

frame (7).

(a)

Remove three nuts (14) from studs (15).

TR01426

(b)

Remove stator assembly (10) from rear

frame (7).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |