|

|||

|

|

|||

|

Page Title:

TURBOCHARGER ASSEMBLY REPAIR - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

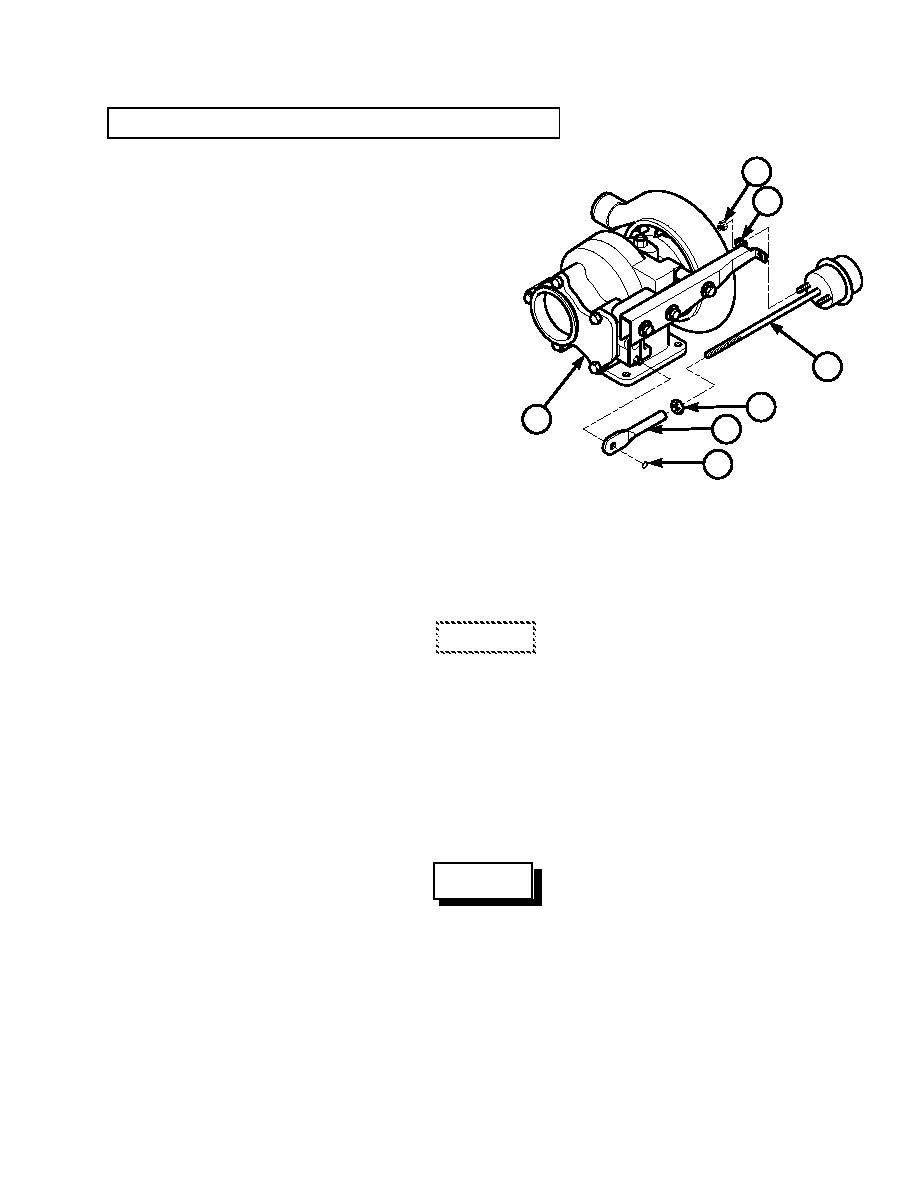

4-6. TURBOCHARGER ASSEMBLY REPAIR (CONT)

(31)

Install nut (7) and adjusting link (3)

4

on boost capsule actuator (5).

6

(32)

Install boost capsule actuator (5) and

two locknuts (4) on bracket (6).

Tighten locknuts to 40 lb-in

(4.5 Nm).

(33)

Install turbocharger

(TM 10-3930-673-20).

(34)

Measure boost capsule actuator (5)

5

travel. Specified travel should be

0.013 to 0.050 in. (0.33 to 1.3 mm).

7

1

3

(a)

Attach a dial indicator to the

turbine housing (1).

2

TR01384

(b)

Set dial indicator to zero.

(c)

Connect 27.7 psi (191 kPa) regulated air pressure to boost capsule actuator (5).

(d)

Measure boost capsule actuator (5) travel. If travel is less than 0.013 in. (0.33 mm) or greater

than 0.050 in. (1.3 mm) replace boost capsule actuator.

CAUTION

Do not force alignment of boost capsule actuator or adjusting link may cause damage to

parts.

(35)

Install boost capsule actuator (5), and adjusting link (3) on turbine housing (1) control

lever.

(a)

Position turbine housing (1) lever towards boost capsule actuator (5).

(b)

Adjust the adjusting link (3) length to where adjusting link aligns with turbine housing (1)

lever.

WARNING

Use care when installing snap and retaining rings. Snap and retaining rings are under

spring tension and can act as projectiles when released and could cause severe eye

injury.

(c)

Install adjusting link (3) and retaining ring (2) on turbine housing (1) lever.

(36)

Disconnect regulated air pressure from boost capsule actuator (5).

END OF TASK

4-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |