|

|||

|

|

|||

|

Page Title:

CONNECTING RODS AND BEARINGS REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

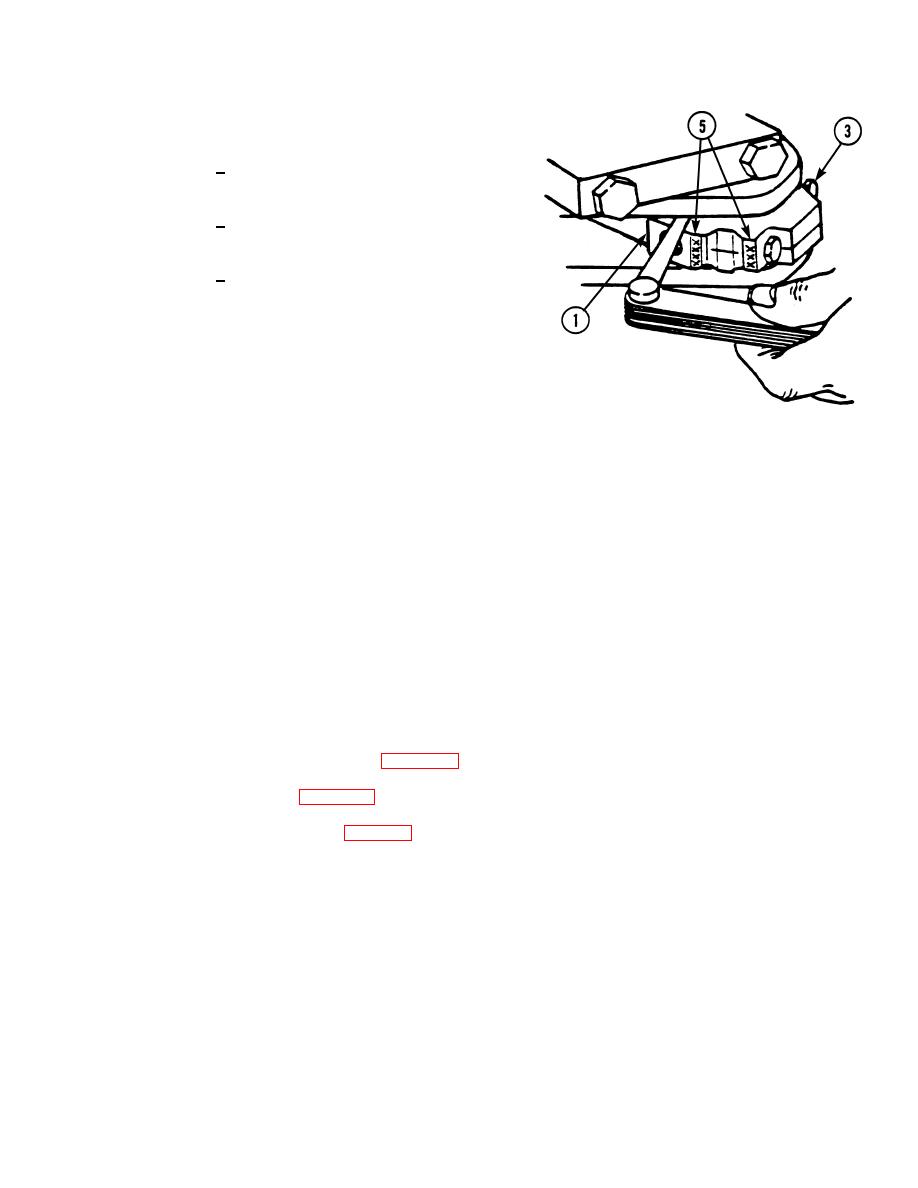

(m) Tighten screws (3) in three

increments.

1

First increment - 26 lb-ft

(35.25 Nm).

2

Second increment - 52 lb-ft

(70.50 Nm).

3

Third increment - 73 lb-ft

(98.97 Nm).

(3)

As bearing caps (1) are installed,

manually rotate crankshaft (9) to

ensure that crankshaft rotates

freely. If crankshaft fails to rotate

freely at some point, check for

installation or incorrect size of rod

TR01639

bearings (4).

(4)

Repeat Steps (2) and (3) for remaining piston (2) and connecting rod assemblies (5) are

installed

(5)

Measure connecting rod (5) side play at each connecting rod (5) assembly.

(a)

Measure connecting rod (5) side play.

(b)

Wear tolerance is 0.012 in (0.30 mm).

(c)

If side play exceeds wear tolerance stated in Step (b), replace connecting rod (5) and bearing

cap (1).

NOTE

Follow-on Maintenance:

Install oil pump inlet tube (Para 3-24).

Install oil pan (Para 3-23).

Install cylinder head (Para 3-7).

END OF TASK

3-117

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |