|

|||

|

|

|||

|

Page Title:

CONNECTING RODS AND BEARINGS REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

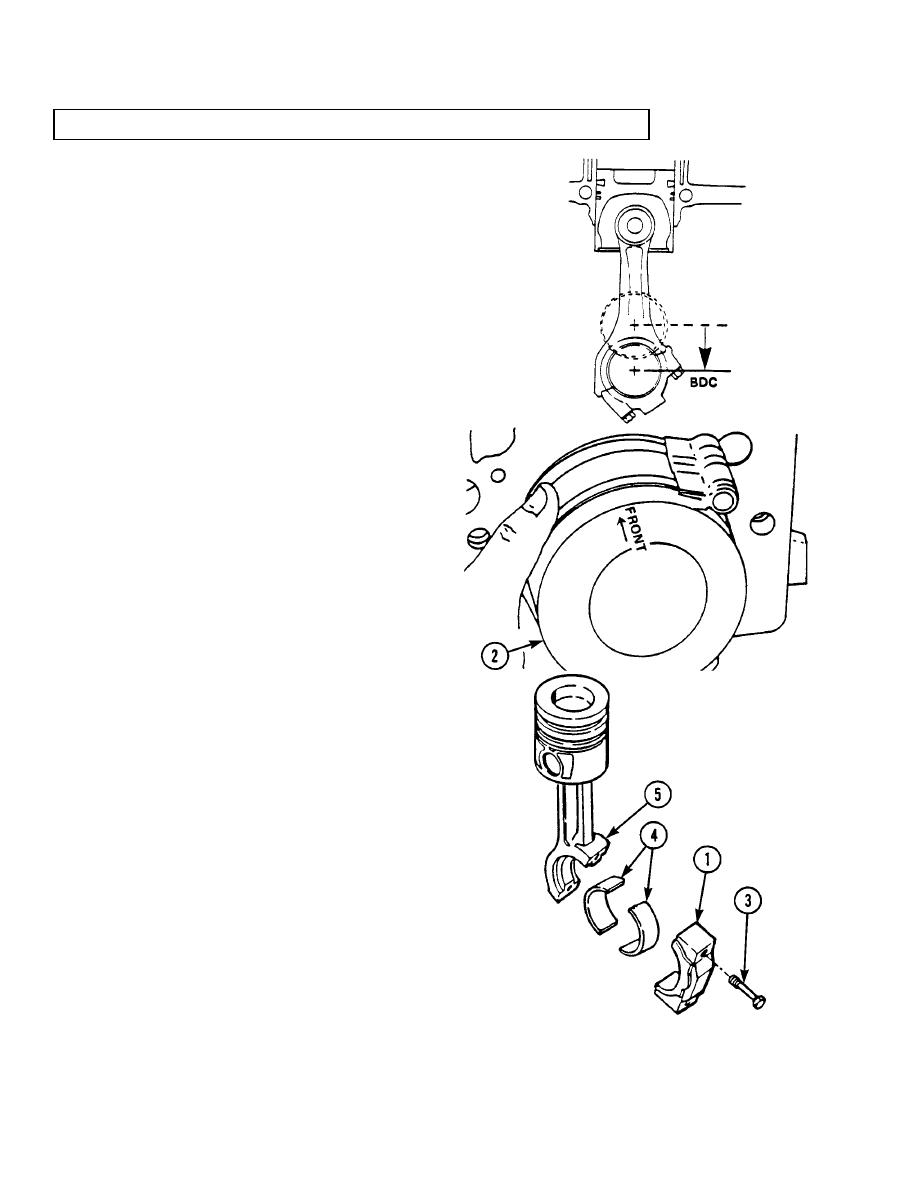

3-17. CONNECTING RODS AND BEARINGS REPLACEMENT (CONT)

(c)

Bar crankshaft (9) over so rod

journal for piston (2) and connecting

rod (5) assembly being installed is at

bottom dead center (BDC).

(d)

Install piston (2) and connecting

rod (5) assembly through top of

cylinder bore, using care not to

damage cylinder liner walls. Make

sure that side of piston containing

word, "FRONT," faces front (fan end)

of engine.

(e)

Continue to push piston (2) into

cylinder bore until top of piston is

approximately 2 in. (50.8 mm) below

top surface of cylinder block.

(f)

Repeat above procedure until all six

piston (2) and connecting rod (5)

assemblies are installed.

(g)

Obtain proper sized rod bearing set,

according to rod bearing clearance

measurement, in Inspection

Steps (4)(d) and (4)(e).

(h)

Install rod bearings (4) in

connecting rods (5) and bearing

caps (1).

(i)

Apply light coat of Lubriplate 105 to

rod bearing (4) bearing surfaces.

(j)

Grasp bottom of connecting rod (5)

and pull downward onto

crankshaft (9) rod journal.

(k)

Install bearing caps (1) with four-

digit numbers stamped on bearing

caps and on connecting rods (5), at

parting line, towards oil cooler side

of engine.

(l)

Apply engine lubricating oil to

threads and under heads of

screws (3). Install screws in bearing

cap (1) and connecting rod (5).

Tighten screws fingertight.

TR01638

3-116

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |