|

|||

|

|

|||

|

Page Title:

PISTONS, PISTON PINS, AND RINGS REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

c. Inspection.

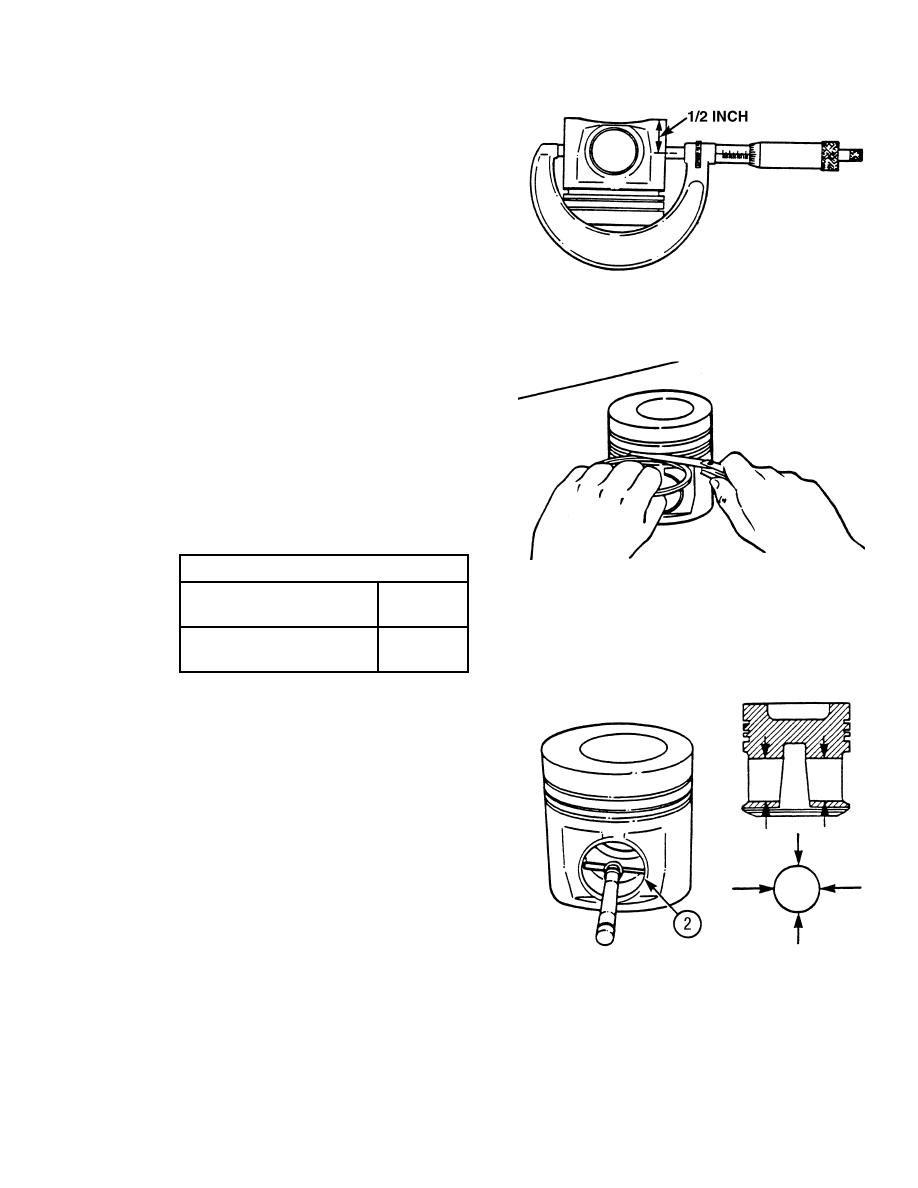

(1)

Visually inspect ring grooves, piston

top, piston skirt, and piston pin bore

for cracks or other damage and for

excessive wear.

(2)

Check piston skirt diameter using an

inside micrometer as shown, at a

point approximately 1/2 in. (12.7 mm)

TR01062

above bottom edge of piston.

Minimum allowable skirt diameter is

4.0088 in. (101.82 mm).

(3)

Check top piston ring for nicks,

cracks or other visible defects. Ring

clearance check is not required for

top piston ring.

(4)

Check ring clearance in

intermediate and oil control ring

grooves using new rings and a feeler

gauge as shown. Maximum allowable

clearances for these two grooves are:

Limit

TR01063

Intermediate ring groove

0.006 in.

(0.15 mm)

Oil control ring groove

0.005 in.

(0.13 mm)

(5)

Check piston pin bore diameter at

four points noted. Maximum

allowable bore diameter is 1.5758 in.

(40.03 mm).

TR01064

3-107

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |