|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

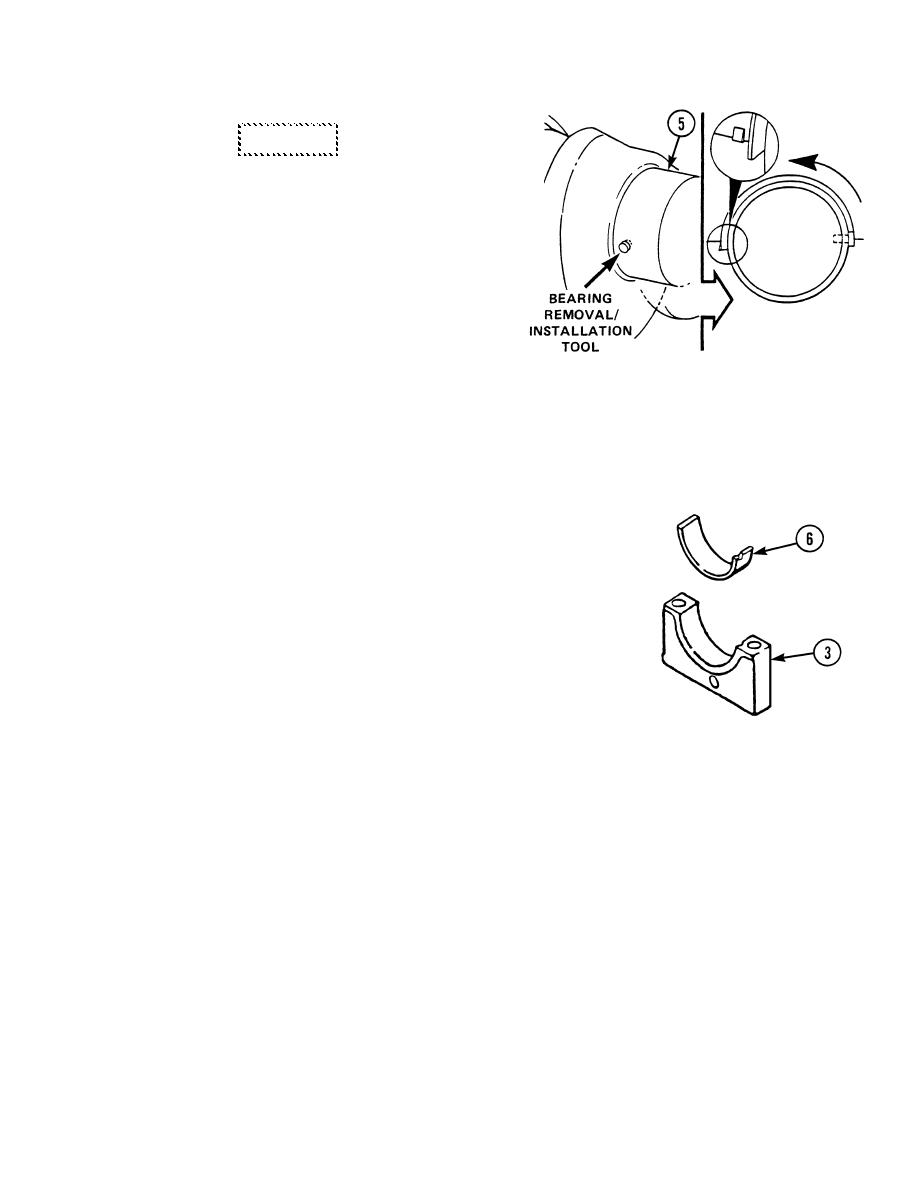

CAUTION

If crankshaft is turned in the wrong

direction, the tab on the upper

bearing half will be pushed between

the crankshaft and main bearing

bore in the block. This could cause

damage to the block and the

crankshaft.

(c)

Install bearing removal/installation

tool into oil hole in crankshaft (1)

journal for main bearing being

TR01417

removed.

(d)

Slowly turn crankshaft (1) so the

special pin pushes against the end of the bearing opposite the tab, and upper bearing half (5)

is out of the cylinder block.

(e)

Remove bearing removal/installation tool from crankshaft (1) oil hole.

(f)

Remove lower bearing half (6) from

bearing cap (3). Keep main bearings

and bearing caps together as a set.

NOTE

When bearings are reused, each

bearing set must be installed in its

original location because the

bearing surfaces have worn to the

crankshaft journals.

TR01421

(g)

Repeat Steps (a) through (f) for

remaining main bearings

positions (2 through 5) and thrust

bearing (2) at main bearing position 6.

(3)

Install main bearing (5 and 6) halves in positions (2 through 6).

(a)

Be sure bearing bore surfaces in the cylinder block are clean and dry.

(b)

Check that the backsides of main bearing halves (5 and 6) are clean and dry.

(c)

Check that inside surfaces of bearing caps (3) are clean and dry.

3-79

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |