|

|||

|

|

|||

|

Page Title:

CRANKSHAFT MAIN BEARINGS REPLACEMENT |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

3

This Task Covers:

a. Removal

c. Inspection

b. Cleaning

d. Installation

INITIAL SETUP

Equipment Condition

Tools and Special Tools

Vehicle parked on level ground

Tool Kit, General Mechanic's: Automotive

Oil pan removed (Para 3-23)

(Item 23, Appendix D)

Oil pump inlet tube removed (Para 3-24)

Shop Equipment, Automotive Maintenance,

Common No. 2 Less Power

Materials/Parts

(Item 17, Appendix D)

Oil, Lubricating, Engine (Item 27, Appendix B)

Shop Equipment, Automotive Maintenance and

Plastigage (Item 32, Appendix B)

Repair; Field Maintenance, Basic, Less Power

Rags, Lint-free (Item 34, Appendix B)

(Item 18, Appendix D)

Solvent, Drycleaning (Item 52, Appendix B)

Bearing Removal/Installation Tool - Fabricated

Lubriplate (Item 23, Appendix B)

Tool (Figure C-7, Appendix C)

Dial Indicator (Item 3, Appendix D)

a. Removal.

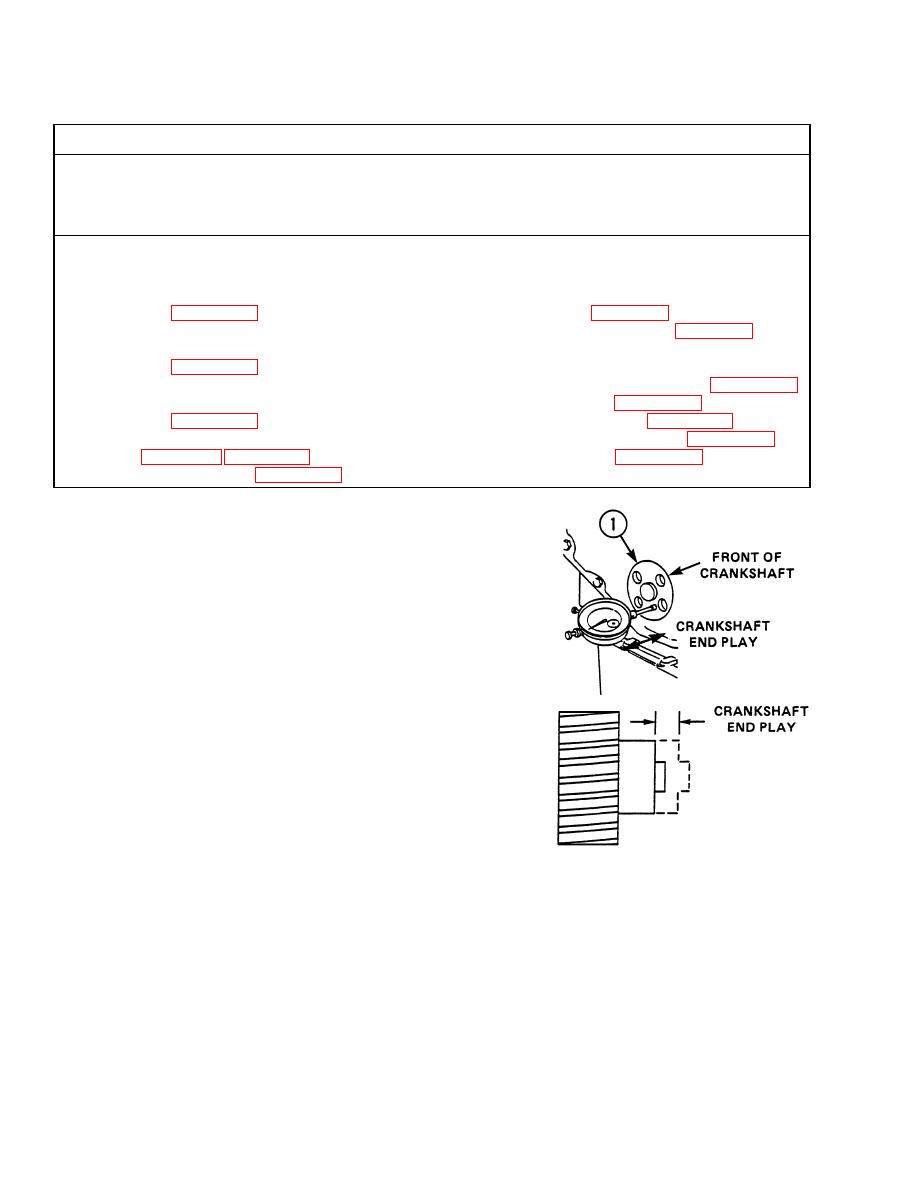

(1)

Check crankshaft (1) end play.

(a)

End play is controlled by the

dimensions of the thrust bearing (2)

and crankshaft (1) journal at the

no. 6 main bearing position.

(b)

Measure crankshaft (1) end play

using a dial indicator as shown in

this illustration.

(c)

Push crankshaft (1) forward, then

toward rear of engine. Record end

play measurement. This data will be

needed later during thrust bearing

installation.

TR01415

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |