|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

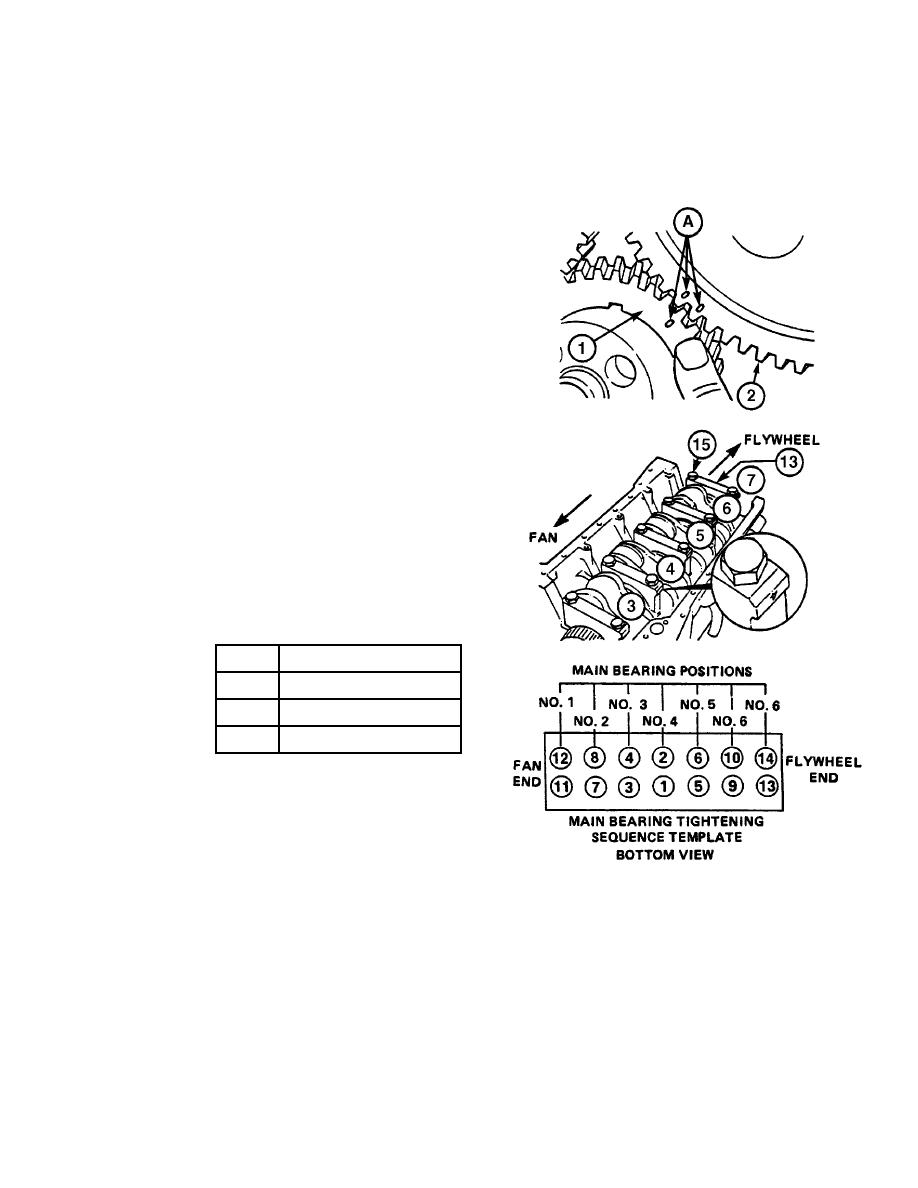

(e)

Apply Lubriplate 105 to the inside surfaces of the upper and lower bearing halves (14 and 18)

and thrust bearing (19).

(f)

Slowly lower crankshaft into cylinder block. Be careful not to scratch the crankshaft journals.

(g)

Check that the crankshaft gear (1)

to camshaft gear (2) timing marks

are aligned at point "A", then allow

crankshaft to firmly rest against the

upper bearing halves (18).

NOTE

The number on the bearing caps

must correspond to the numbers in

the cylinder block and they must be

towards the oil cooler side of the

engine.

(h)

Install seven bearing caps (13) and

14 screws (15). Tighten screws

finger tight.

(i)

The main bearing screws (15) must

be tightened evenly in a series of

three steps, and in the sequence

shown in this illustration. The

torque value for each step is shown

in this chart.

Step

Torque Value

1

44 lb-ft (59.66 Nm)

2

88 lb-ft (119.31 Nm)

3

129 lb-ft (174.90 Nm)

(4)

Check crankshaft (16) end play.

NOTE

End play is controlled by the

dimensions of the thrust bearing

TR01175

and crankshaft journal at the no. 6

main bearing position.

(a)

Measure crankshaft (16) end play using a dial indicator as shown in this illustration.

(b)

Push crankshaft (16) forward, then toward rear of engine. With a new thrust bearing, end

play limits must not exceed 0.005 - 0.010 in. (0.13 - 0.25 mm).

(c)

If end play measurement is greater than 0.010 in. (0.25 mm), install a larger size thrust

bearing (19).

3-67

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |