|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

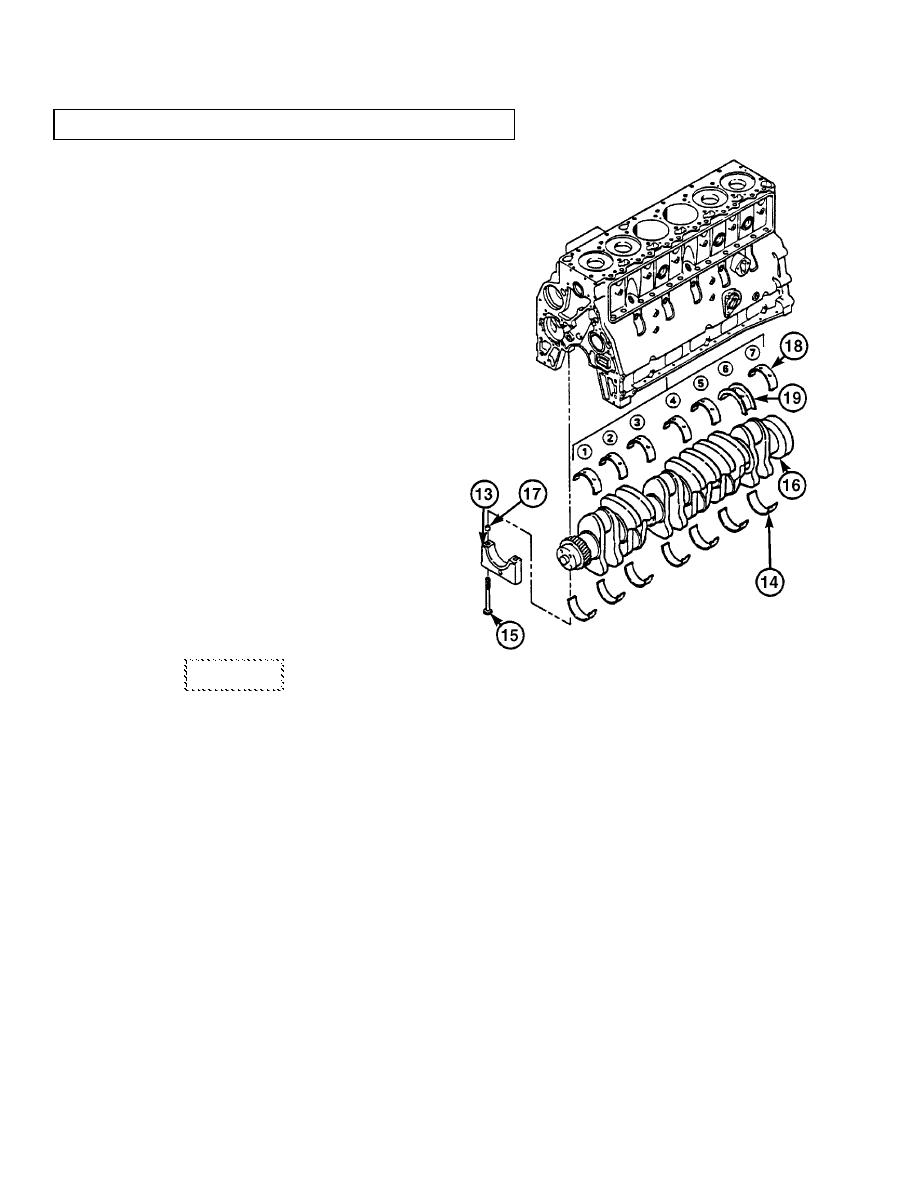

3-8. CRANKSHAFT REPLACEMENT/REPAIR (CONT)

NOTE

If clearance exceeds tolerance listed

below proceed to Steps (m) and (n).

If clearance does not exceed

tolerance proceed to Step (3)(h).

(l)

Remove and measure plastigage.

Main bearing clearance must not

exceed 0.00474 in. (0.120 mm). If

bearing clearance exceeds clearance

measurement, use appropriate

oversize bearings.

(m) Remove lower bearing halves (14)

from bearing caps (13).

(n)

Lift crankshaft (16) from cylinder

block (4) far enough to remove upper

bearing halves (18) and thrust

bearing (19). Be careful that

connecting rods do not scratch

crankshaft.

(3)

Install upper and lower bearing

halves (14 and 18).

TR01174

CAUTION

Be sure cylinder block bearing

bores, backsides of bearings, and

inner surface of bearing caps are

clean and dry. Oil on these areas

could cause less heat transfer

between the bearings and the block

which, in turn, could cause

overheated bearings.

(a)

If removed, install 14 ring dowels (16) in bearing caps (13).

(b)

Place lower bearing halves (14) in bearing caps (13) with tab inserted in cap groove.

(c)

At main bearing positions (1 through 5, and 7), align tab of upper bearing half (18) with

groove in bearing bore (cylinder block), and press bearing half into place.

(d)

Align tab of thrust bearing (19) with groove in cylinder block at main bearing position (6) and

press thrust bearing into place.

3-66

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |