|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-673-34

3

3-8. CRANKSHAFT REPLACEMENT/REPAIR

This Task Covers:

a. Removal

c. Cleaning

e. Assembly

b. Disassembly

d. Inspection

f. Installation

INITIAL SETUP

Materials/Parts

Tools and Special Tools

Gloves, Insulated (Item 17, Appendix B)

Tool Kit, General Mechanic's: Automotive

Lubriplate (Item 23, Appendix B)

(Item 23, Appendix D)

Oil, Lubricating, Engine (Item 27, Appendix B)

Shop Equipment, Automotive Maintenance,

Plastigage (Item 32, Appendix B)

Common No. 2 Less Power

Bearings, Connecting Rod

(Item 17, Appendix D)

Bearings, Connecting Rod

Shop Equipment, Automotive Maintenance and

Bearings, Main

Repair; Field Maintenance, Basic, Less Power

Bearings, Main

(Item 18, Appendix D)

Bearing, Thrust

Nylon Straps, 200 lb (90.72 kg) capacity)

Gasket

Lifting Device, 200 lb (90.72 kg) capacity)

Pin, Roll

Dial Indicator

Screws (2)

Engine Stand

Wear Sleeve, Front

Gear Puller

Wear Sleeve, Rear

Inside Micrometer, 3 in. (76.2 mm)

Inside Micrometer, 4 in. (101.6 mm)

Equipment Condition

Engine removed (Para 3-3)

Flywheel housing and cover removed

Front housing cover only removed (Para 3-21)

Engine oil pan removed (Para 3-23)

a. Removal.

(1)

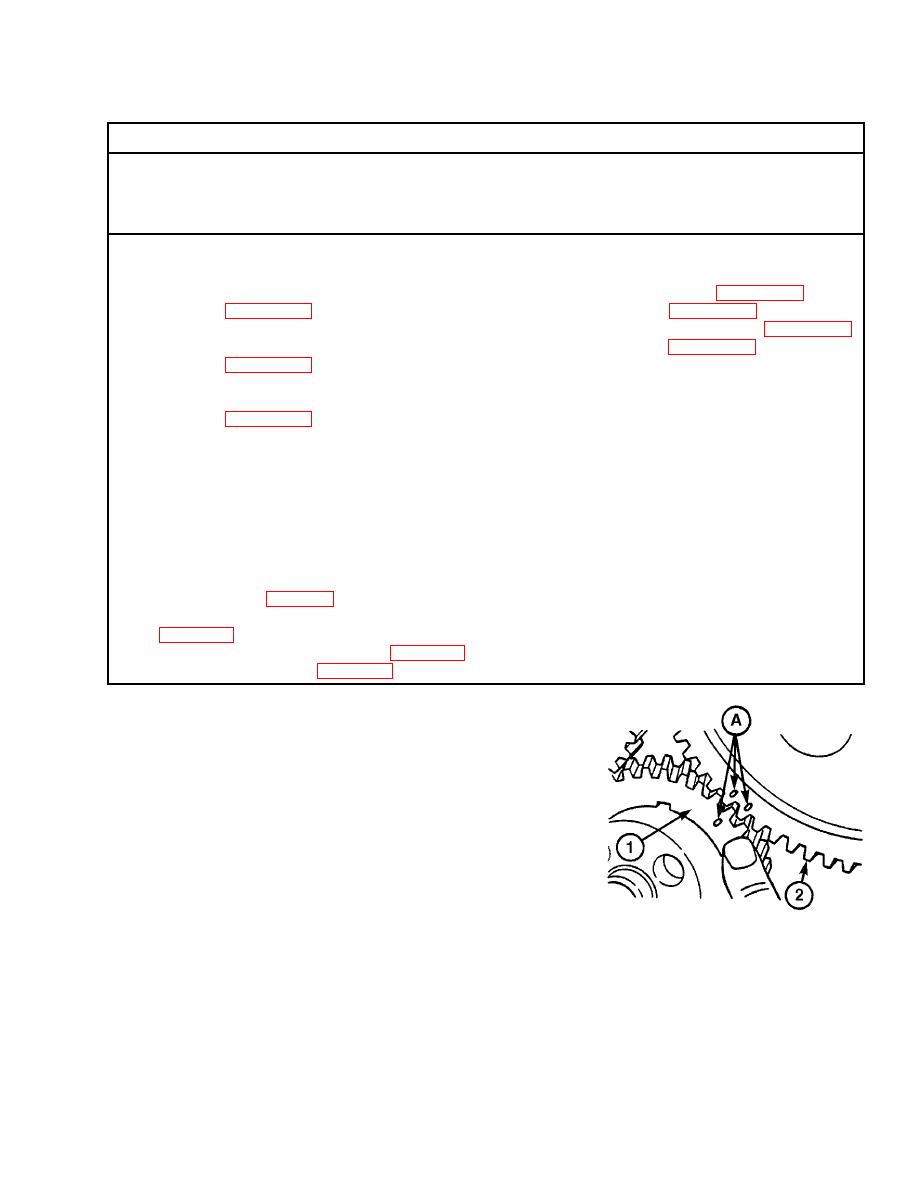

Align and mark crankshaft gear (1)

and camshaft gear (2).

Turn crankshaft until timing mark (A) on

crankshaft gear (1) is aligned with timing

mark (A) on the camshaft gear (2).

TR01165

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |