|

|||

|

|

|||

|

Page Title:

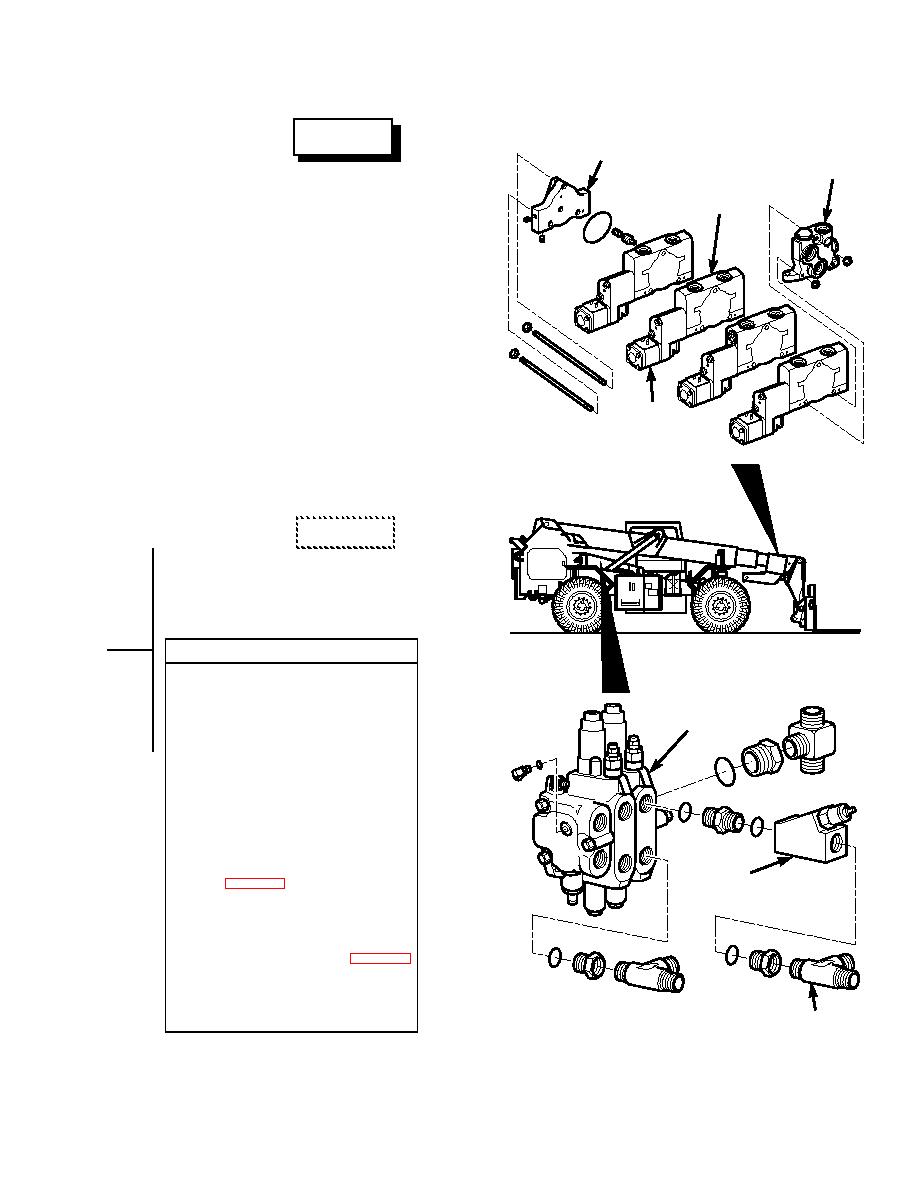

LEAKS BETWEEN ATTACHMENT/MAIN CONTROL VALVE SECTIONS - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

WARNING

OUTLET

INLET

HOUSING

HOUSING

ATTACHMENT

Compressed air used for cleaning purposes will

VALVE

not exceed 30 psi (207 kPa). Use only with

SECTIONS

effective chip guarding and personal protective

equipment (goggles/shield, gloves, and so forth).

Drycleaning Solvent (P-D-680) is TOXIC and

flammable. Wear protective goggles and gloves; use

only in a well-ventilated area; avoid contact with skin,

eyes, and clothes; and do not breathe vapors. Keep

away from heat or flame. Never smoke when using

solvent; the flashpoint for type I drycleaning solvent

is 100F (37.8C), type II is 138F (59C), and type

III is 200F (93.3C). Failure to do so may result in

injury or death to personnel.

Adhesives, solvents, and sealing compounds can

burn easily, can give off harmful vapors, and are

ELECTRIC-

harmful to skin and clothing. To avoid injury or death, keep

HYDRAULIC

away from open fire and use in a well-ventilated area. If

ASSEMBLIES

adhesive, solvent, or sealing compound gets on skin or

clothing, wash immediately with soap and water.

CAUTION

Wipe area clean around all hydraulic connections to be

opened during removal. Cap oil lines and plug holes

after removing lines. Contamination of the hydraulic

system could result in premature failure.

VISUAL INSPECTION

(1) Separate the various sections of the

attachment control valve and/or main

MAIN CONTROL

control valve.

VALVE SECTIONS

(2) Visually inspect preformed packings

between sections for crimps, breaks,

and/or other damage.

(a) If preformed packings are free from

signs of crimps, breaks, and/or

other damage, determine if

sections were assembled in correct

order. Go to Step (3) below.

(b) If preformed packings are crimped,

broken, or show signs of other

damage, replace faulty packings

FLOW

CONTROL

Step (3) below.

VALVE

(3) Assemble the various sections of the

attachment control valve and/or main

control valve in correct order on tie rod.

(4) Torque tie rods as specified (Para 16-4

and 16-5).

(5) Install attachment control valve and/or

main control valve

(TM 10-3930-673-20).

FITTINGS TO

HYDRAULIC LINES

2-59

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |