|

|||

|

|

|||

|

Page Title:

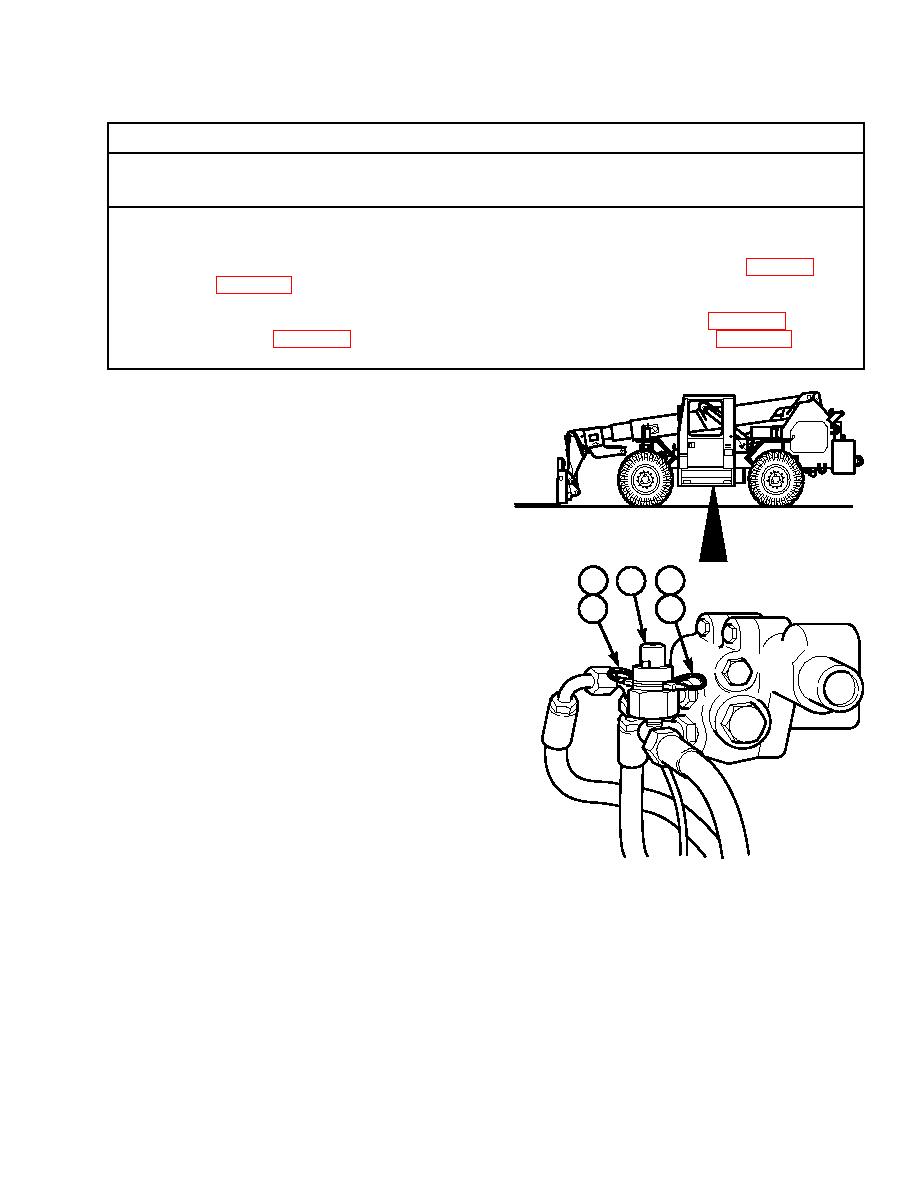

BRAKE HYDRAULIC PRESSURE SWITCH TEST/REPLACEMENT |

|

||

| ||||||||||

|

|

TM 10-3930-673-20-2

6

This Task Covers:

a. Test

b. Removal

c. Installation

INITIAL SETUP

Equipment Condition

Tools and Special Tools

Negative battery cable disconnected (Para 8-44)

Tool Kit, General Mechanic's: Automotive

(Item 18, Appendix F)

Materials/Parts

Compound, Sealing (Item 32, Appendix C)

Test Equipment

Varnish, Anti-fungus (Item 42, Appendix C)

Ohmmeter (Item 10, Appendix F)

Container

a. Test.

(1)

Tag, mark, and remove two connectors (1)

from connectors (2) on brake hydraulic

pressure switch (3).

(2)

Connect ohmmeter across connectors (2) on

brake hydraulic pressure switch (3).

TR00004

(3)

Test brake hydraulic pressure switch (3) for

continuity.

1

1

3

2

2

(a)

With engine OFF, pump brake pedal a

minimum of 20 times to exhaust stored

brake system pressure.

(b)

Observe ohmmeter. Ohmmeter should

show continuity.

(c)

Start vehicle and allow brake system

accumulator to charge.

(d)

Observe ohmmeter. Ohmmeter should

show no continuity.

(e)

Turn engine OFF.

TR00320

(f)

If brake hydraulic pressure switch (3)

does not pass continuity test, brake

hydraulic system must be repaired.

(g)

If brake hydraulic pressures are within normal range, brake hydraulic pressure switch (3) must be replaced

as described in Removal and Installation sections below.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |