|

|||

|

|

|||

|

Page Title:

FUEL TRANSFER PUMP REPLACEMENT/TESTING (CONT) |

|

||

| ||||||||||

|

|

TM 10-3930-673-20-2

NOTE

Fuel transfer pump should produce at least 0.7 U.S. quarts of fuel in container during Step (3)(c)

below. If fuel volume is too low, replace fuel transfer pump (refer to Removal and Installation

sections of this paragraph).

(c)

Crank engine for thirty seconds (TM 10-3930-673-10).

(d)

Remove test hose from fuel transfer pump (2).

(4)

Test fuel transfer pump (2) for adequate pressure.

(a)

Connect pressure gage to fuel transfer pump (2) at port where fuel hose (1) was removed.

NOTE

Fuel transfer pump should provide 10 psi (70 kPa) during Step (4)(b) below. If fuel pressure is too low,

replace fuel transfer pump (refer to Removal and Installation sections of this paragraph).

(b)

Crank engine and observe reading on gage.

(c)

Remove pressure gage from fuel transfer pump (2).

NOTE

Perform Steps (5) through (7) below only if fuel transfer pump is not to be replaced.

(5)

Install fuel hose (1) on fuel transfer pump (2).

(6)

Bleed fuel hose (1) (refer to Step (6) of Installation section in this paragraph).

(7)

Place auxiliary fuel shut-off switch in `on' position (TM 10-3930-673-10).

b. Removal.

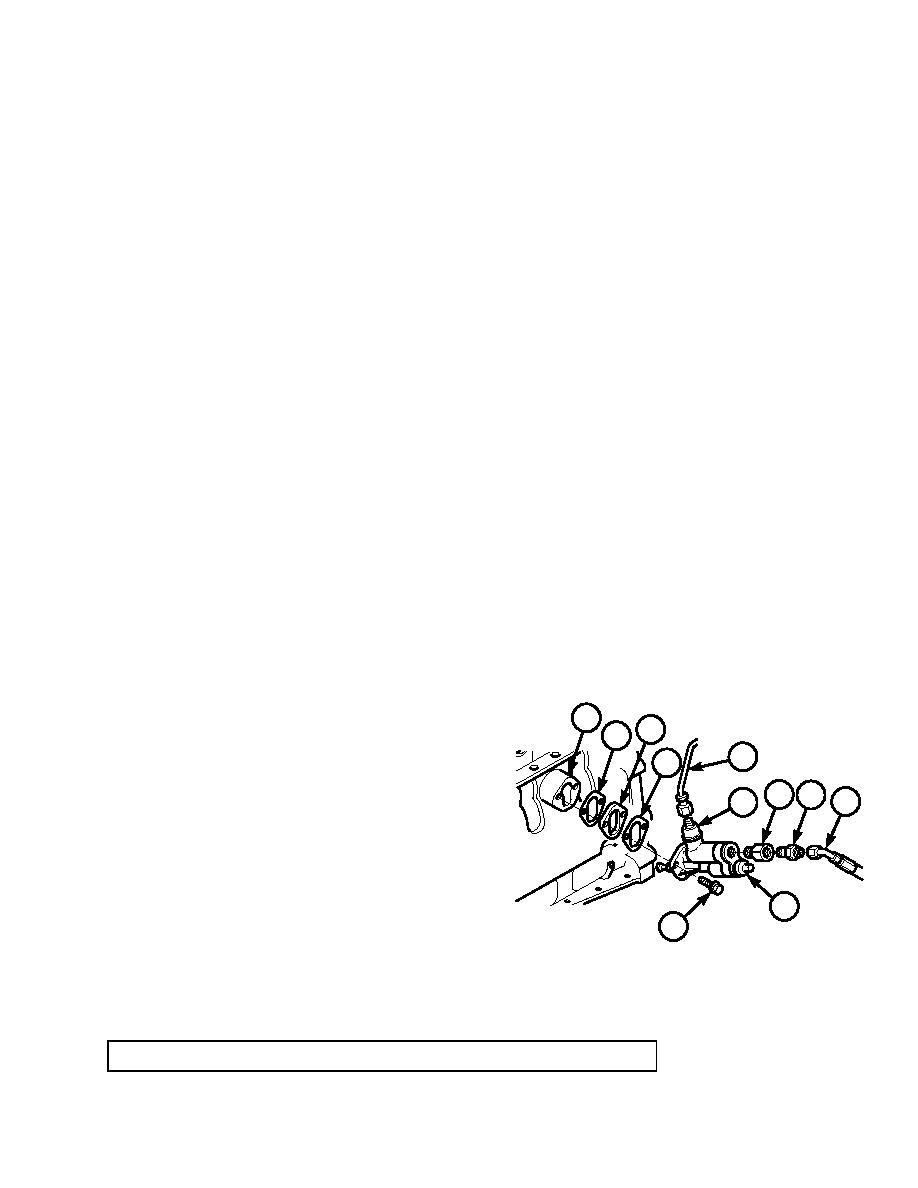

9

8

7

NOTE

4

7

Perform Step (1) below only if fuel

10

3

transfer pump was not tested. If fuel

1

5

transfer pump was tested, fuel line will

already be disconnected.

(1)

Disconnect fuel hose (1) from adapter (3).

2

(2)

Remove fuel tube (4) from adapter (5).

6

(3)

Remove two screws (6), fuel transfer pump

TR00160

(2), two gaskets (7) and spacer (8) from

engine block (9). Discard gaskets.

(4)

Remove adapters (3) and (10) from fuel transfer pump (2).

5-3. FUEL TRANSFER PUMP REPLACEMENT/TESTING (CONT)

5-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |