|

|||

|

|

|||

|

Page Title:

HIGH TRANSMISSION TEMPERATURE INDICATOR DOES NOT OPERATE - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-20-1

RESISTANCE CHECK

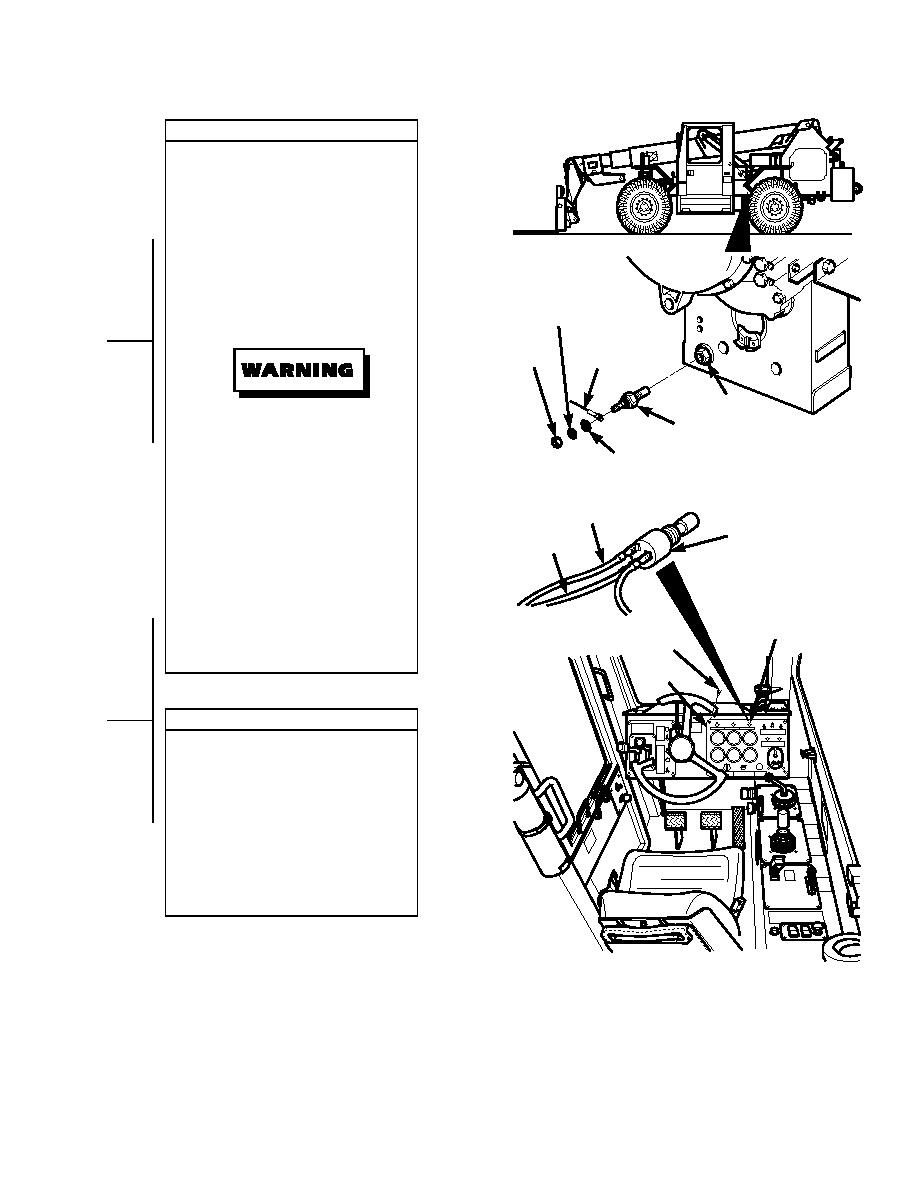

(1) Remove nut, lockwasher, washer, and

wire 18 from transmission temperature

switch.

(2) Remove transmission temperature

switch from reducer.

(3) Hang transmission temperature switch

in pan of water. Do not let switch make

contact with pan.

(4) Place a thermometer in water.

(5) Put heat to pan of water and stir water

for consistent temperature of 200F

LOCKWASHER

(93.3C). Allow water temperature to

stabilize for 15 minutes.

NUT

WIRE 18

REDUCER

Do not allow fingers or skin to contact

TRANSMISSION

hot water or hot parts. Serious burns

TEMPERATURE

to personnel could result.

SWITCH

WASHER

(6) Set multimeter to ohms.

(7) Connect multimeter positive lead (+) to

stud of transmission temperature

HIGH TRANSMISSION

WIRE 18

switch.

TEMPERATURE

(8) Connect multimeter negative lead () to

INDICATOR

WIRE 10

hex or large threads of transmission

LIGHT SOCKET

temperature switch.

(a) If 115 to 140 ohms are not

measured, replace transmission

HIGH TRANSMISSION

temperature switch (Para 8-16).

TEMPERATURE

(b) If 115 to 140 ohms are measured,

INDICATOR

install transmission temperature

SCREW

switch (Para 8-16) and go to

Step 5 of this fault.

PANEL

CONTINUITY CHECK

(1) Remove four screws and panel.

(2) Connect multimeter positive lead (+) to

wire 18 at high transmission

temperature indicator terminal.

(3) Using a known good jumper wire,

connect multimeter negative lead () to

TR01505

wire 18 at transmission temperature

switch terminal.

(a) If continuity is not present, replace

wire 18 (Para 8-48).

(b) If continuity is present, go to Step 6

of this fault.

2-407

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |