|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

TORQUE LIMITS

SCOPE

This work package lists standard torque values and provides general information for applying torque. Special torque val-

ues and tightening sequences are indicated in the maintenance procedures for applicable components.

GENERAL

1.

Always use torque values listed in Tables 1 and 2 when a maintenance procedure does not give a specific torque value.

a.

Table 1 provides torque limits for SAE standard fasteners.

b.

Table 2 provides torque limits for metric fasteners.

Unless otherwise indicated, standard torque tolerance shall be 10%.

2.

3.

Torque values listed are based on clean, dry threads. Reduce torque by 10% when engine oil is used as a lubricant.

Reduce torque by 20% if new plated capscrews are used.

4.

If the maintenance procedures do not specify a tightening order, use the following guides:

a.

Unless otherwise specified, lubricate threads of fasteners with oil (OEA-10).

b.

When tightening fasteners above 30 lb-ft (41 Nm), use the torque pattern but only tighten to 70% of final value

(multiply final value by 0.7). Repeat pattern until final value is reached.

c.

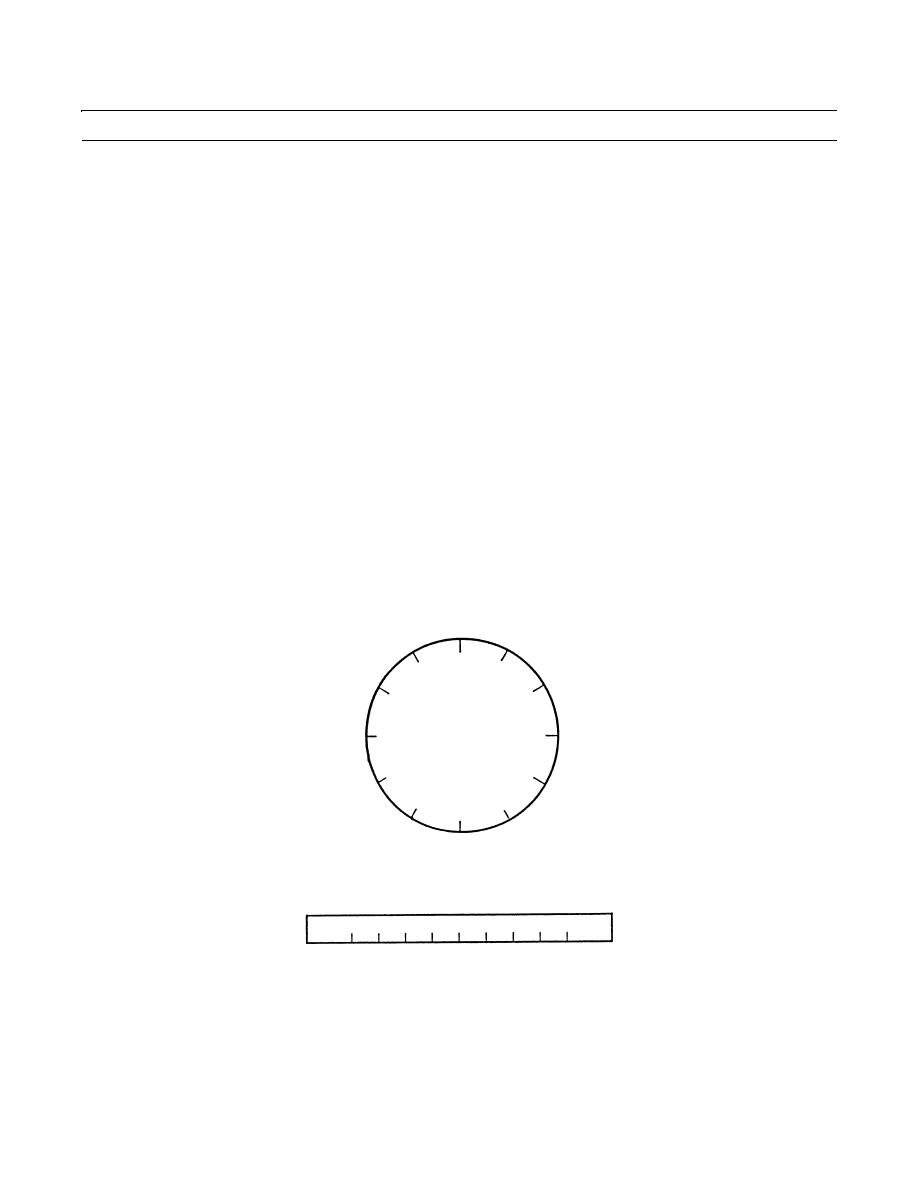

Tighten circular patterns using circular torque pattern and tighten straight patterns using straight torque pattern.

1

8

5

12

10

4

3

11

9

6

7

2

CIRCULAR TORQUE PATTERN

8

531246

9

7

STRAIGHT TORQUE PATTERN

CAUTION

If replacement capscrews are of higher grade than originally supplied, use torque specifications for the orig-

inal. This will prevent equipment damage due to overtorquing.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |