|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

TRANSMISSION ASSEMBLY REPAIR - CONTINUED

0289 00

ASSEMBLY - CONTINUED

CAUTION

Use care when installing piston to prevent damage to O-ring and outer piston seal.

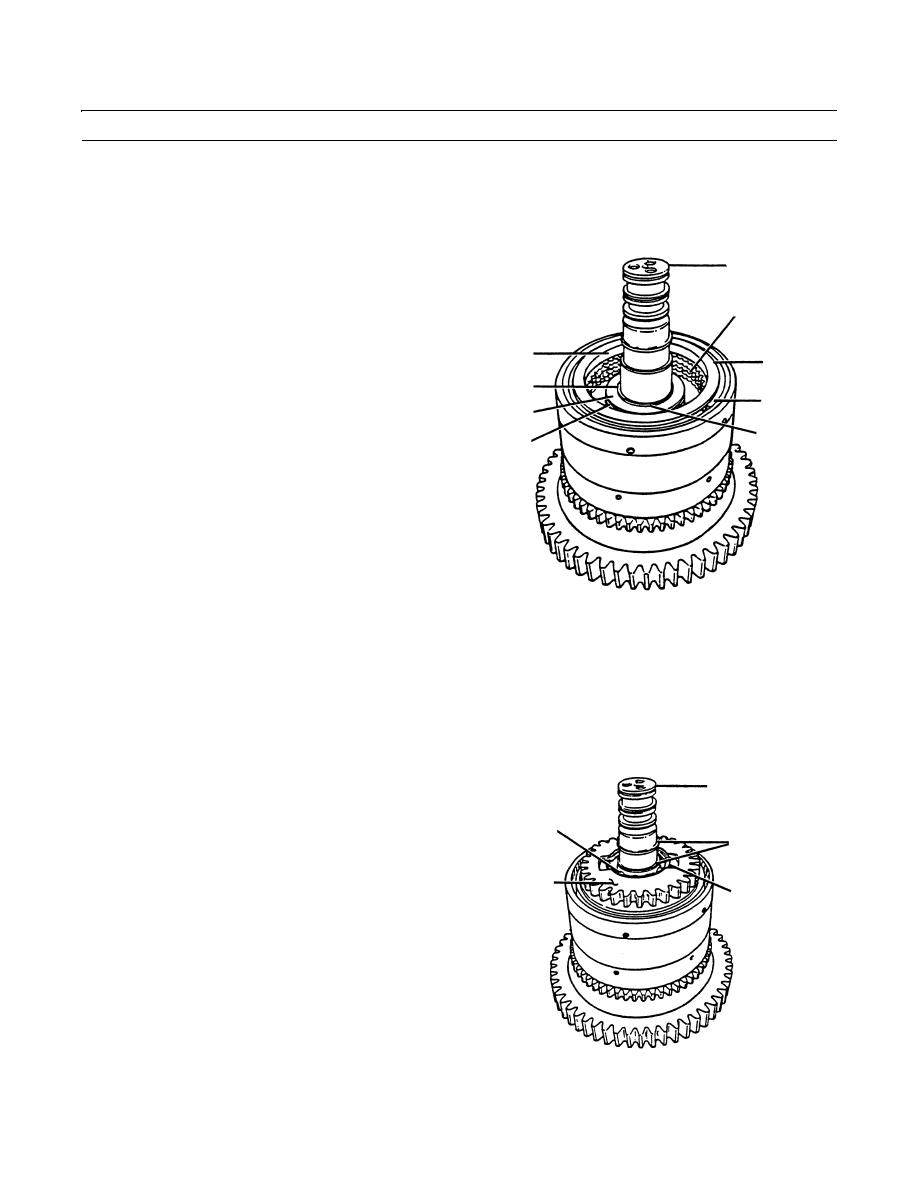

46.

Install assembled piston (64) into shaft assembly (49).

49

Ensure that piston (64) aligns with locating pins in

shaft assembly (49).

57,58

47.

Install thrust washer (62), four springs (61) and

retainer (59).

64

56

48.

Place shaft assembly (44) in a press. Install a spring

59

compressor tool.

55

61

WARNING

60

62

Ensure that retainer ring is secure in

groove before spring compressor tool is

removed from retainer to prevent springs

from flying out. Failure to follow this pre-

caution could cause personal injury.

49.

Press down on spring compressor tool and retainer

409-4117

(59) to allow installation of retainer ring (60). Slowly

remove spring compressor tool.

CAUTION

Carefully handle clutch plates so graphite coating does not flake off. Failure to follow this precaution could

cause equipment damage.

50.

Install four clutch plates (57) and four separator plates (58) into shaft assembly (49). Begin with a separator plate (58)

and then a clutch plate (57). Continue by alternating plates. The last plate must be a clutch plate (57).

NOTE

49

The separator plates have external teeth

and clutch plates have internal teeth. The

53

plates do not have a right or wrong side for

51

installation.

52

51.

Install clutch plate retainer (56) and snap ring (55) on

54

shaft assembly (49).

52.

Install appropriate pair of alignment bars between

weld gear (52) and piston (64), as required, to hold

weld gear (52) off piston (64). Use either narrow or

wide side of bars to ensure that weld gear (52) is held

off piston (64) 1/16 in. (1.6 mm) and at the same time

engages all clutch plates (57).

409-1168

0289 00-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |