|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

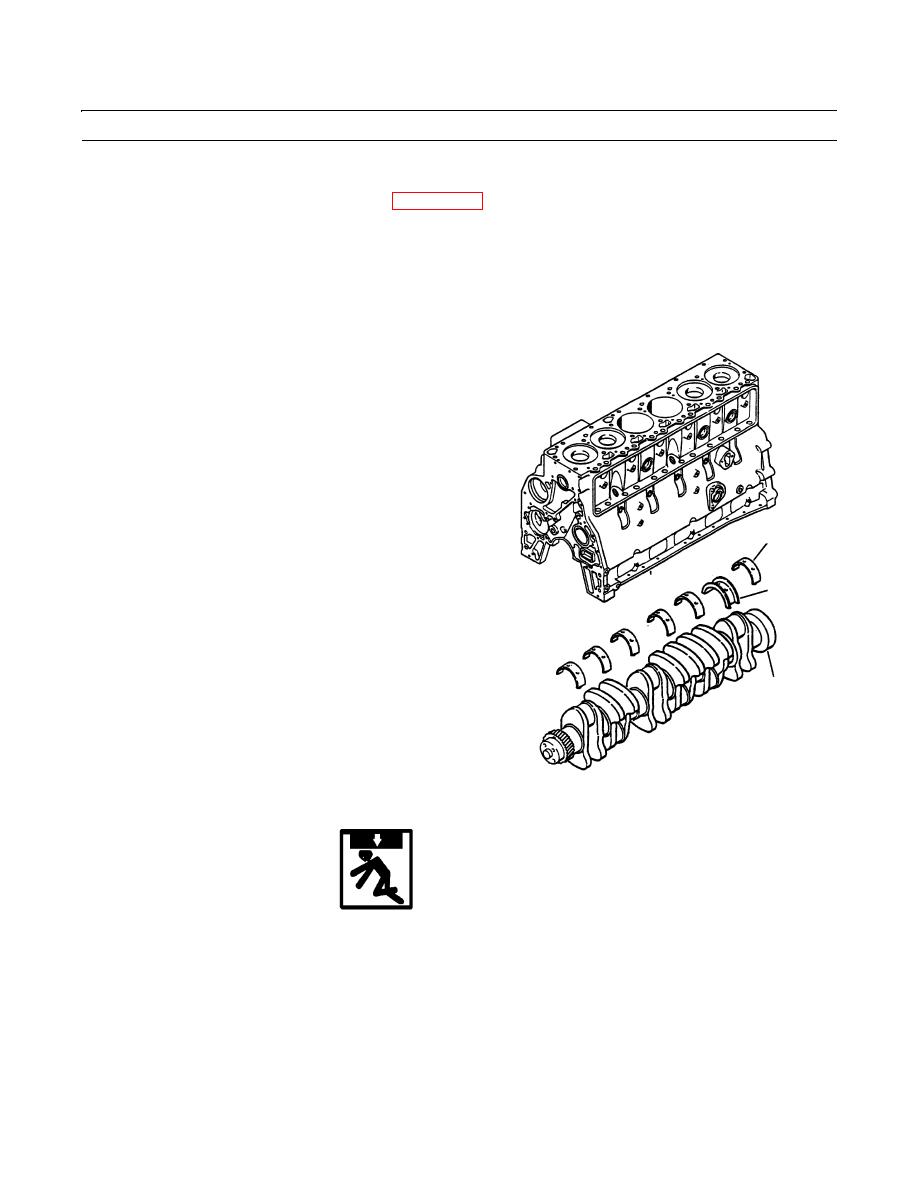

CRANKSHAFT MAINTENANCE - CONTINUED

0271 00

INSTALLATION

1.

Clean main bearing surfaces in cylinder block (WP 0273 00).

NOTE

If the crankshaft journals have been ground, appropriate oversize bearings will need to be installed.

Install new main bearings dry at this time. Be sure cylinder block bearing bores, backsides of bearings, and

inner surface of bearing caps are clean and dry.

2.

Check main bearing and thrust bearing clearance by

aligning tab of new upper main bearing half (17) with

groove in crankshaft bearing bore (cylinder block),

and press bearing half into place. Perform this proce-

dure for main bearing positions (1 thru 5 and 7).

3.

Install thrust bearing (18) in crankshaft bearing bore

no. 6 with tab in bearing bore groove.

17

18

14

409-911

WARNING

Use caution when handling heavy parts. Provide adequate support and use assistance during procedure.

Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of heavy

parts supported only by lifting device. Failure to follow this warning may cause injury or death.

CAUTION

Use only nylon straps, or equivalent, to install crankshaft into cylinder block. Be sure that nothing metallic

comes in contact with the machined surfaces of the crankshaft. A scratched or damaged crankshaft could

cause premature engine failure.

0271 00-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |