|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

INNER BOOM MAINTENANCE - CONTINUED

0262 00

INSTALLATION - CONTINUED

NOTE

Adjust hoist and sling as required during following steps to provide work room when installing wear pad

assemblies.

All used wear pads installed in following steps must be at least 3/8 in. (9.5 mm) thick. If wear pad is worn to

less than 3/8 in. (9.5 mm) thick, discard old wear pad and replace with new wear pad.

Shims are used as required. Install same quantity of shims as noted during removal.

10.

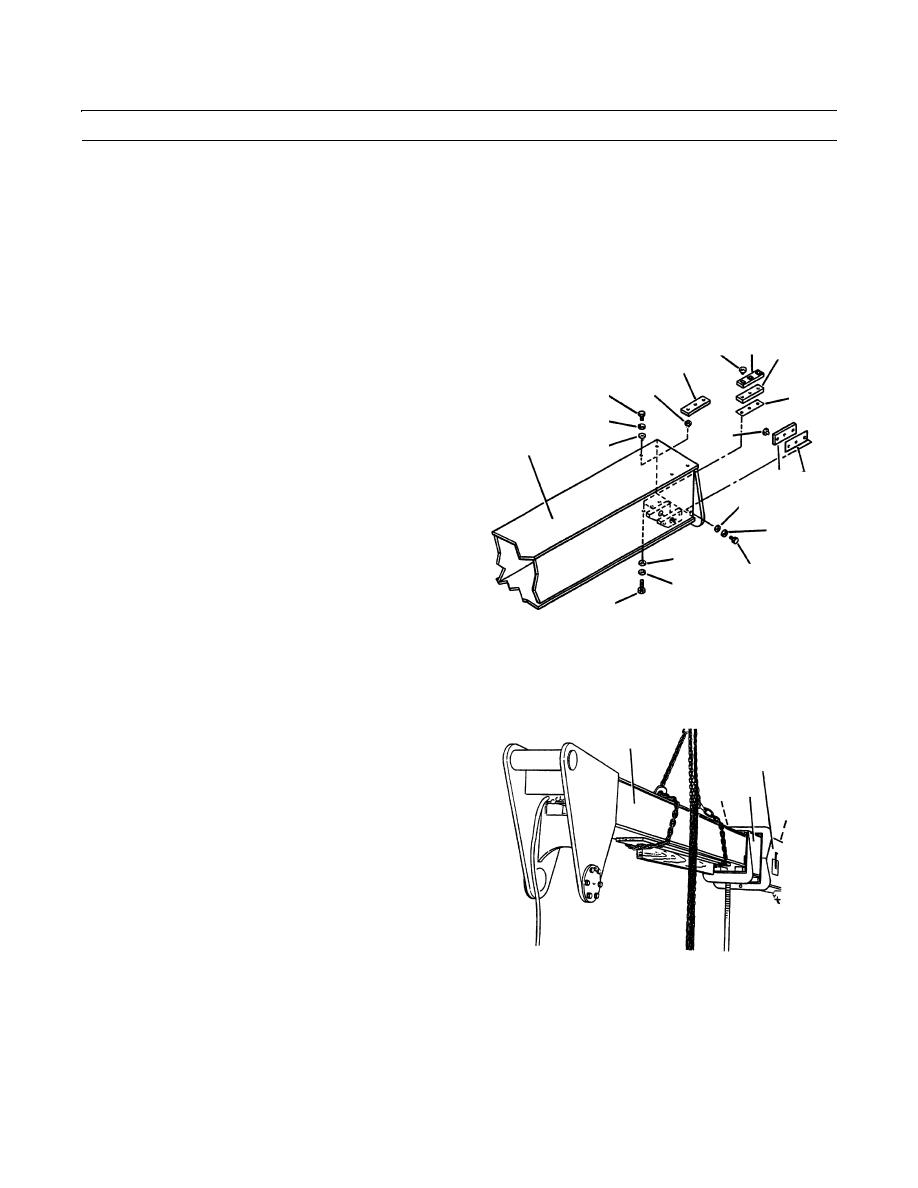

Lift inner boom (2) to provide adequate space between

56

57

58

inner boom (2) and intermediate boom (11).

41

11.

Position spacers (58), shims (59 and 60), wear pads

42

43

59,60

(56) and wear pad inserts (57) between intermediate

44

boom (11) and inner boom (31). Chamfered side of

52

wear pad (56) must be facing towards inner boom

11

45

(31). Widest portion of wear pad (56) must be facing

towards outside of intermediate boom (11).

49 50,51

48

NOTE

47

Apply loctite to capscrews as installed in

steps 12, 14 and 16.

55

46

12.

Secure wear pad assemblies, parts (56 thru 60) to

54

intermediate boom (11) with flatwashers (55), new

409-1409

53

lockwashers (54) and capscrews (53). Torque cap-

screws to 30 lb-ft (41 Nm).

NOTE

Shims are used as required. Install same quantity of shims as noted during removal.

13.

Position wear pads (49), shims (50 and 51) and wear

31

pad inserts (52) between intermediate boom (11) and

2

inner boom (31). Chamfered side of wear pad (49)

13,14,15

25,35 11

must be facing towards inner boom (31). Widest por-

tion of wear pad (49) must be facing towards bottom

37

of intermediate boom (11).

14.

Secure wear pad assemblies, parts (49 thru 52) to

intermediate boom (11) with flatwashers (48), new

lockwashers (47) and capscrews (46). Torque cap-

screws to 30 lb-ft (41 Nm).

409-1440

15.

Position wear pads (44) and wear pad inserts (45) between intermediate boom (11) and inner boom (31). Chamfered side

of wear pad (44) must be facing towards inner boom (31). Widest portion of wear pad (44) must be facing towards out-

side of intermediate boom (11).

16.

Secure wear pad assemblies, parts (44 and 45) with flatwashers (43), new lockwashers (42) and capscrews (41). Torque

capscrews to 30 lb-ft (41 Nm).

0262 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |