|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

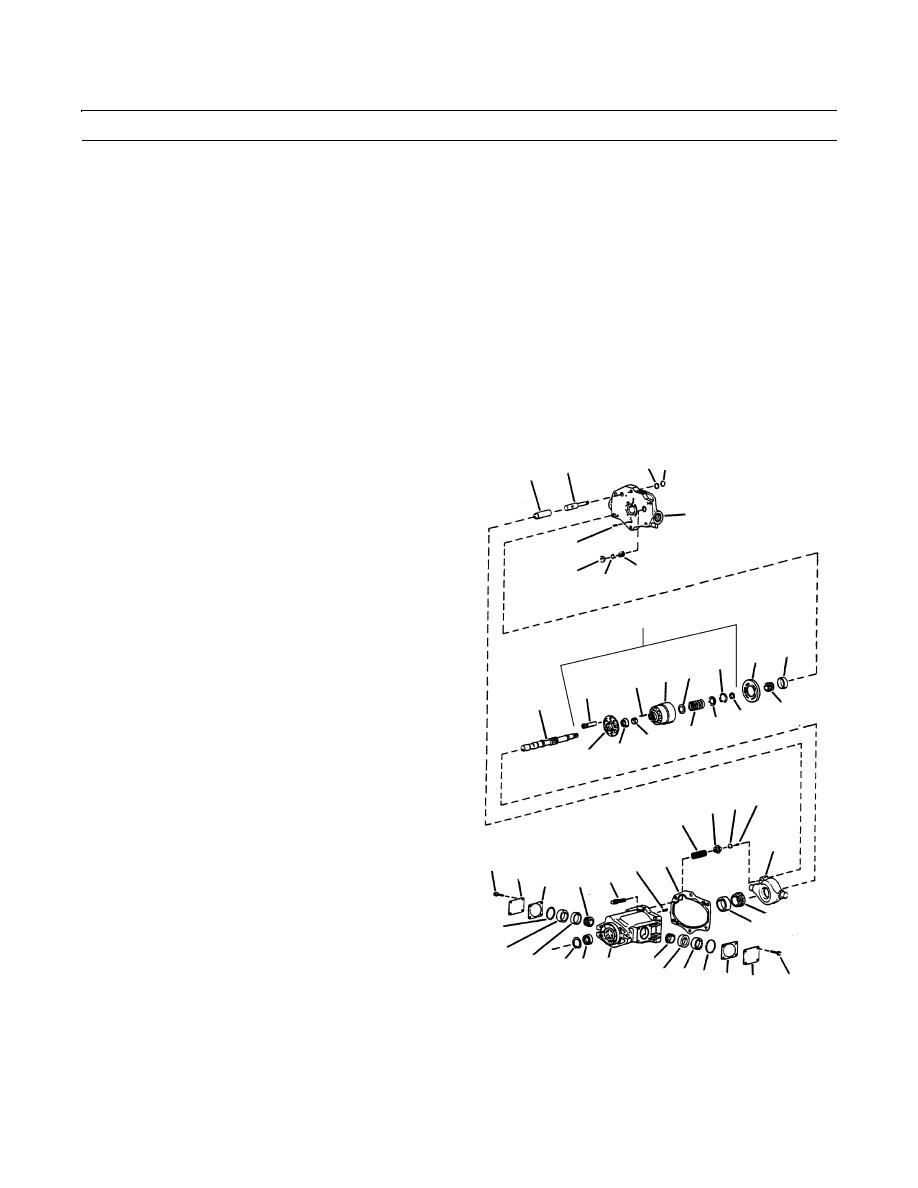

PISTON PUMP MAINTENANCE - CONTINUED

0256 00

ASSEMBLY - CONTINUED

NOTE

The side of the wafer plate with the locating pin groove must face the valve block.

46.

Assemble wafer plate (11) over bearing race (48) and plate groove over locating pin (12).

CAUTION

Wafer plate must be flat against valve block face. Check to make sure it does not rock back and forth. If

rocking motion occurs, make sure locating pin is bottomed out in the valve block. Wafer plate rocking will

induce high stress conditions and cause fractures in the wafer plate.

47.

Place valve block (3) on its side. Install piston rod (8) into valve block (3) and attach retaining ring (47).

48.

Install new O-ring (46) in the piston rod (8) O-ring

47 46

8

7

groove.

CAUTION

3

Be careful not to allow the piston to drop

12

from piston rod as this could damage the

piston.

44

42

43

49.

Install piston (7) over piston rod (8).

18

50.

Assemble valve block (3) to housing (6) with six

screws (9).

48

11

21

51.

Cross-torque screws (9) to bring valve block and

17 23

16

housing evenly together against gasket (10). Torque

23

15

screws (9) to 60-70 lb-ft (81-95 Nm).

13

22 14

20

25

24

19

34 36 37

35

26

49 10

28 29

9

27

31

38

39

32

33

30

31

40 41 6

30 33 32 27 29

28

409-1473

52.

Check shaft torque to verify correct bearing preload. If shaft torque is greater than 6 lb-ft (8 Nm), adjust shaft bearing

preload. See steps 22-27.

0256 00-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |