|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

PISTON PUMP MAINTENANCE - CONTINUED

0256 00

ASSEMBLY - CONTINUED

31.

Use tapered feeler gauge to measure opening between valve block (3) and housing (6). Four measurements should be

obtained equidistant around unit. Average four readings by adding them together and dividing by 4. Calculate thickness

of shaft bearing spacer as shown in the following example:

+ 0.150 in. (3.81 mm) = measured thickness of bearing spacer

- 0.027 in. (0.68 mm) = average gap (estimated)

+0.003 in. (0.076 mm) +

0.001 in. (0.025 mm) = preload setting

+0.020 in. (0.508 mm) = compressed thickness of gasket

0.146 + 0.001 in. = required bearing spacer thickness to provide a 0.003 + 0.001 in. bearing preload

32.

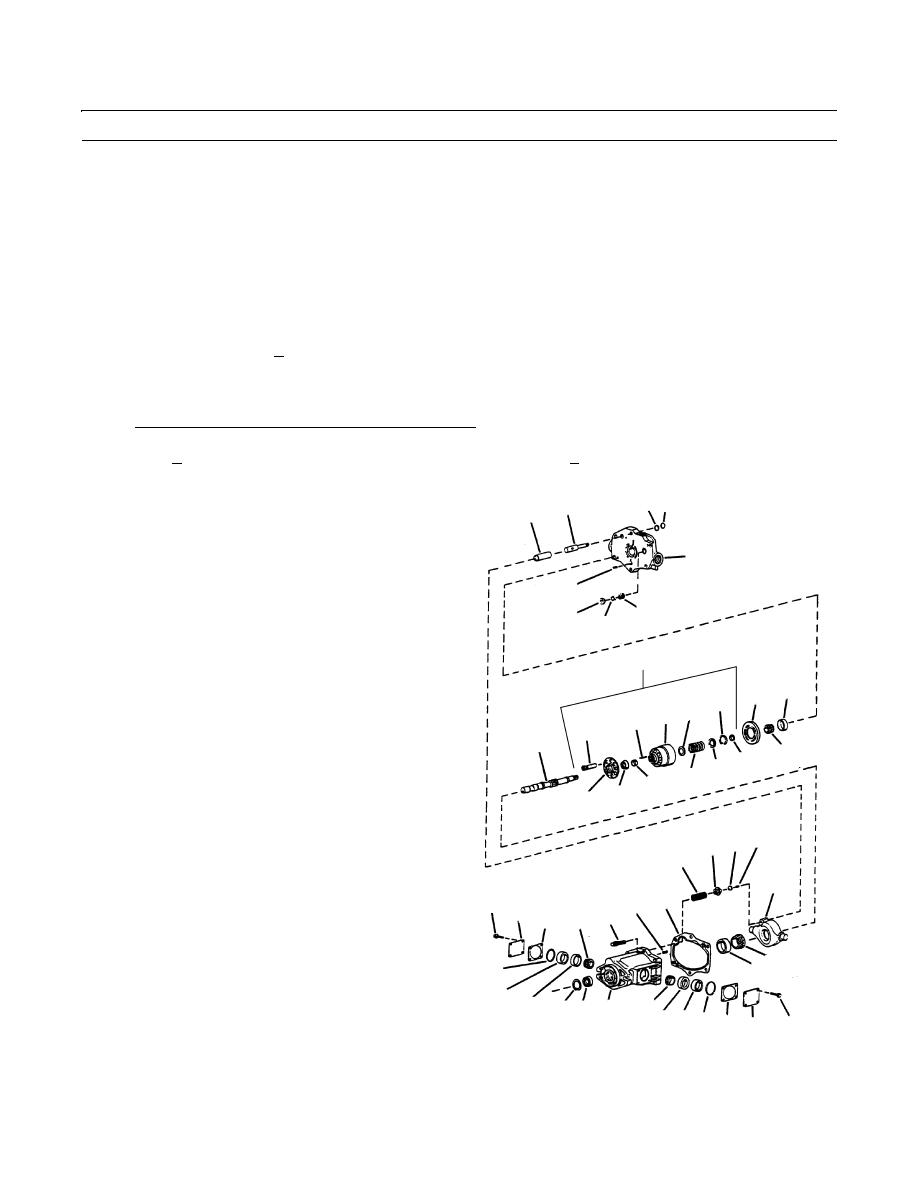

Remove the six mounting screws (8), then remove

47 46

8

7

housing (6) from valve block (3).

33.

Remove bearing (13) and thickest bearing spacer (14)

3

from shaft (15).

34.

Locate bearing spacer (14) in kit with dimensions cal-

12

culated in step 35 above. Place spacer (14) next to the

44

new bearing (13) on shaft (15), with chamfer of spacer

42

43

facing the shaft shoulder. Use the original spacer (14)

and bearing (13) if preload is not required. Set aside

18

until final assembly is performed.

48

11

21

17 23

16

23

15

13

22 14

20

25

24

19

34 36 37

35

26

49 10

28 29

9

27

31

38

39

32

33

30

31

40 41 6

30 33 32 27 29

28

409-1473

0256 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |