|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

FLYWHEEL MAINTENANCE - CONTINUED

0214 00

INSTALLATION

WARNING

Use caution when handling heavy parts. Provide adequate support and use assistance during procedure.

Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of heavy

parts supported by lifting device. Failure to follow this warning may cause injury or death.

CAUTION

Do not use the timing pin to lock the engine. Use a barring tool to hold the engine crankshaft during fly-

wheel installation. Using the timing pin as a locking device while tightening the flywheel mounting hard-

ware could damage the pin.

NOTE

The flywheel weighs more than 50 lb (23 kg).

1.

Attach lifting device and hoist to the flywheel.

9,10

CAUTION

Install new capscrews each time flywheel

is removed to help prevent possible engine

failure.

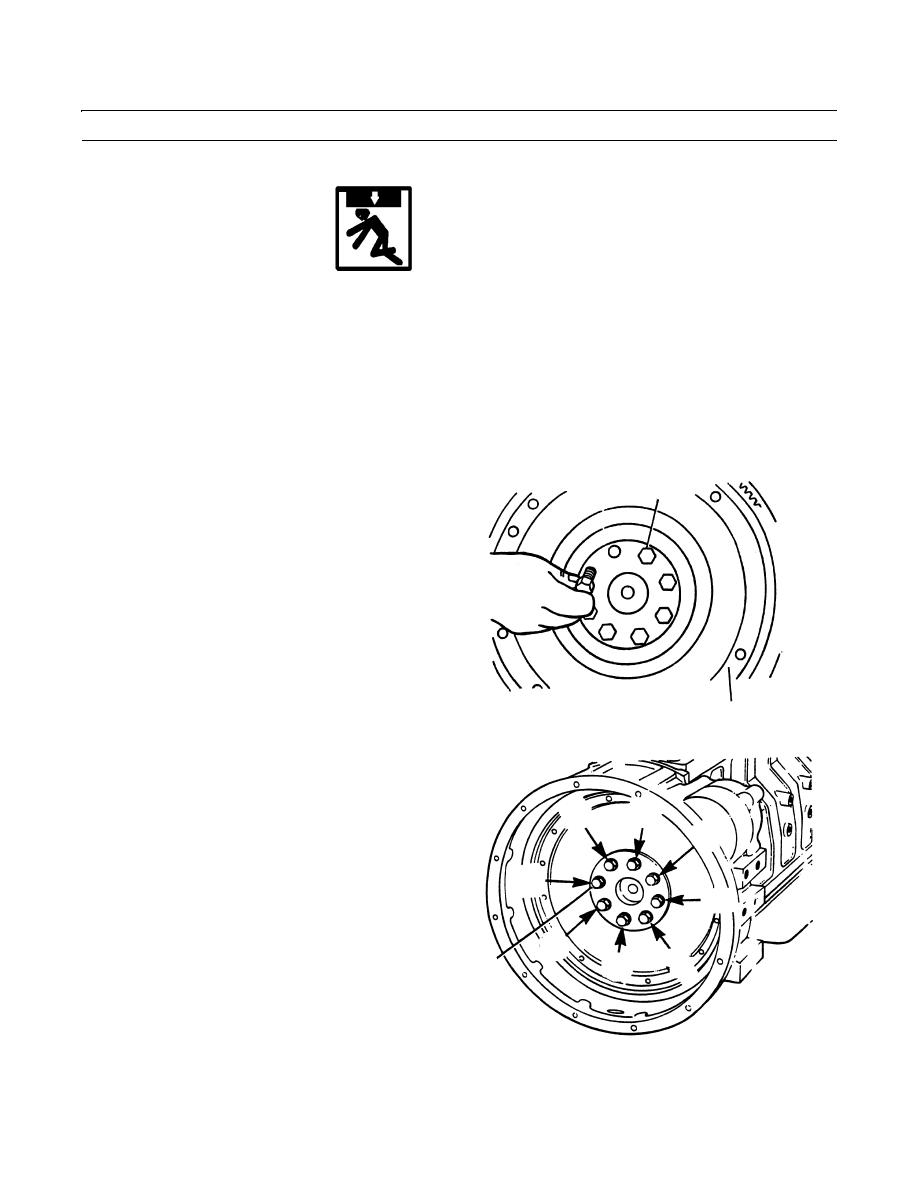

2.

Lift flywheel (11) against end of crankshaft and install

eight new capscrews (9) and new washers (10).

Remove hoist and lifting device.

11

409-967

3.

Install barring tool between long capscrews in vibra-

tion damper.

4.

Firmly hold barring tool to keep flywheel from turn-

1

3

ing, and torque new capscrews (9), in the sequence

5

shown, to 101 lb-ft (137 Nm) torque.

5.

Remove barring tool and two long capscrews.

8

7

6

4

9

2

SEQUENCE DIAGRAM

409-968

0214 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |