|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-1

MLRS ATTACHMENT CYLINDER REPLACEMENT - CONTINUED

0185 00

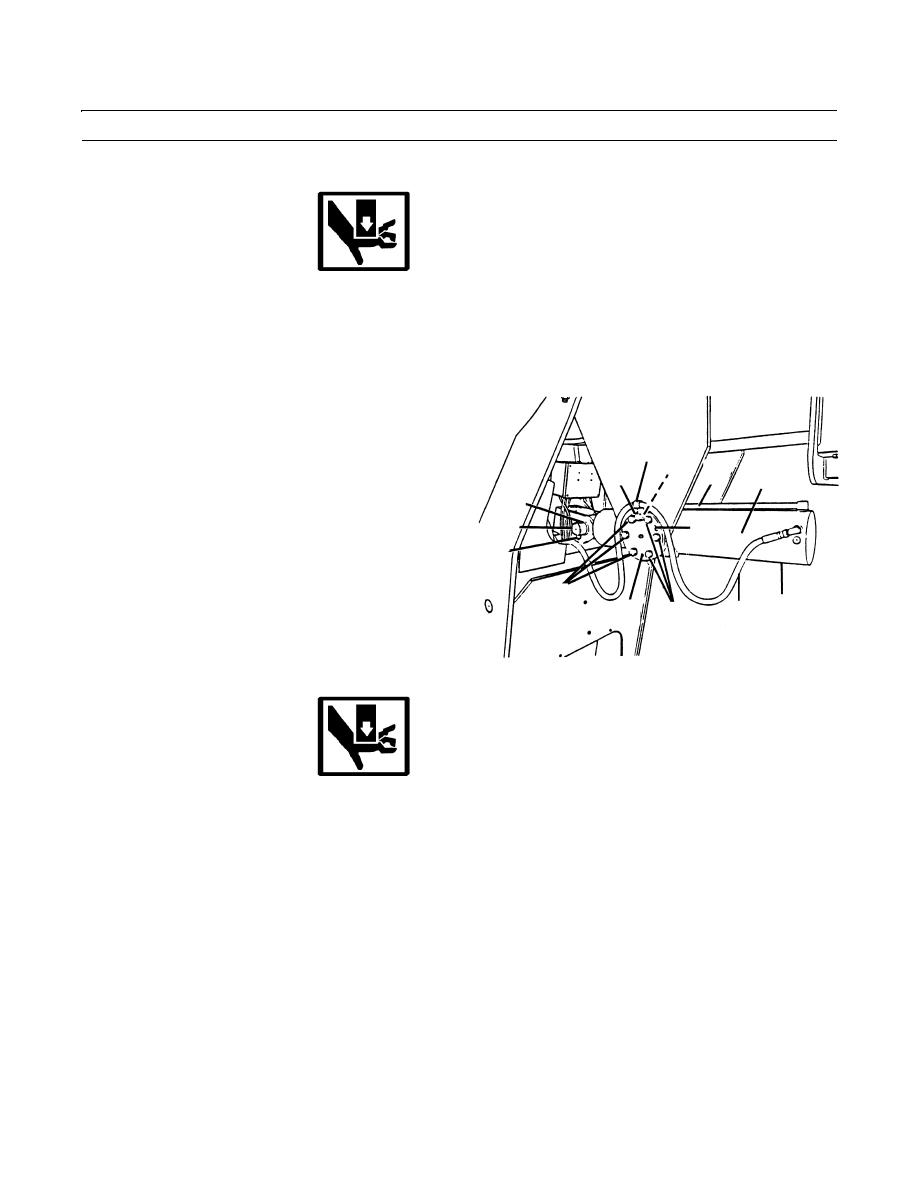

INSTALLATION

WARNING

Failure to support cylinder during installation may cause severe personal injury or damage to equipment.

NOTE

If desired, use a hoist with slings of appropriate length in place of personnel to support cylinder in steps 2

thru 6. Slings must be long enough to lower cylinder to ground without interference from boom.

1.

Support MRLS attachment cylinder (7) using two peo-

ple.

3,4

2.

Install two bearing caps (5) and MLRS attachment

13

cylinder (7).

1,2

B

A

10

NOTE

8

5

Install bearing caps so that jack bolt holes

9

are positioned as shown. Position cylinder

with the rod end oil feed tube (B) up.

11,12

7

6

13

11,12

3.

Apply loctite to six bolts (11).

4.

Install six bolts (11) and six new lockwashers (12).

409-706

5.

Repeat steps 3 and 4 for other bearing cap (5).

WARNING

Failure to support rear portion A of MLRS attachment cylinder when installing pivot pin may cause personal

injury and damage to cylinder.

6.

Support rear portion of MLRS attachment cylinder (7) using a hoist and sling or other suitable lifting device.

NOTE

Apply anti-seize compound to pivot pin.

7.

Install pivot pin (8).

8.

Secure pivot pin (8) with bolt (10) and new locknut (9).

9.

Raise or lower MLRS attachment cylinder (7) as needed to ease pivot pin (8) installation.

10.

Install two hydraulic lines (6). Use tags to identify connections.

11.

Install new lockwasher (4), clamp (3), new lockwasher (2) and capscrew (1) to each of the two bearing caps (5).

0185 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |