|

|||

|

|

|||

|

Page Title:

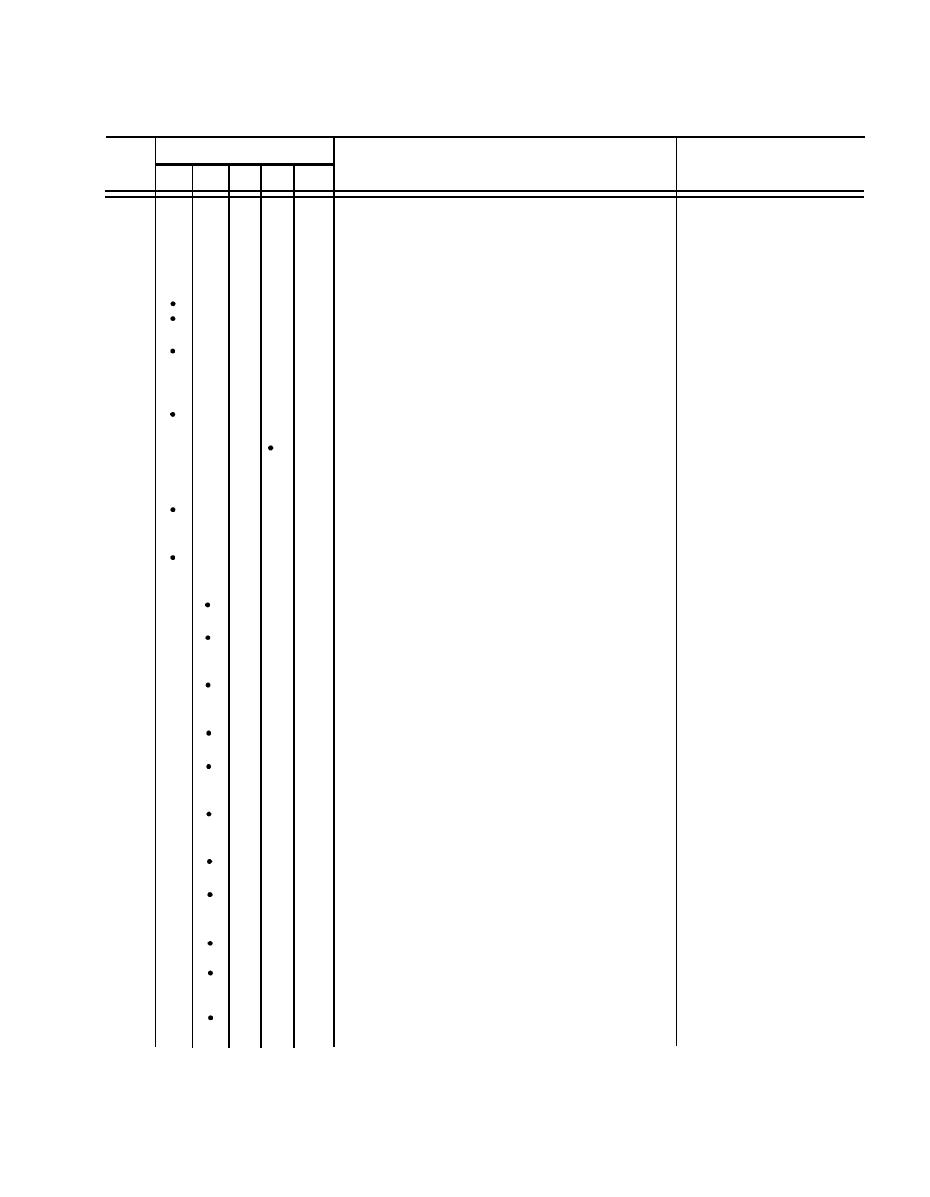

Operator Crew Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 10-3930-647-14&P

Operator Crew Preventive Maintenance Checks and Services

M-Monthly

A-After

W-Weekly

B-Before

D-During

Item to be Inspected

Interval

Procedure: Check for and have repaired, filled or

Equipment is not ready/

Item

W

D

available if:

adjusted as needed

No.

B

D

A

IMPORTANT: Perform Weekly as well as before

operations PMCS if:

1. You are the assigned operator and have not

operated the item since the last weekly.

2. You are operating the item for the first time.

1

EXTERIOR OF VEHICLE

a. Check for leaks or appearance of leaks.

Class I I I leaks or any fuel leaks.

b. Visually check overhead guard for obvious cracks

Obvious cracks in welds.

in web.

2

HYDRAULIC RESERVOIR

Check reservoir oil level, add oil if necessary to bring

level up to full mark on dipstick, when mast is lowered

and all cylinders retracted.

3

TIRES

Check tires for wear and correct pressure (100 psi).

Tire is flat, unserviceable.

4

RADIATOR

Check radiator and fill if necessary to marker tab (add

50/50 mixture of water and antifreeze) (reference TB

750-651).

5

ENGINE OIL LEVEL

Check oil dipstick, add oil, if needed, to raise level to full

mark.

6

AIR CLEANER

Check element to insure it is clean, if not, have

Element is missing or damaged.

organizational replace it.

7

HORN

Check horn by pressing button.

8

BRAKES

Service brake will not stop

Check that brakes stop truck.

truck.

9

STEERING

Steering sticks or truck is hard

Check that truck steers free and easy.

to steer.

10

ACCELERATOR

Check that the accelerator goes smoothly.

Pedal sticks.

11

LIFT LEVER

Check that lifting and lowering is smooth.

Lifting or lowering jerky or un-

controllable.

TILT LEVER

12

Check that forward and backward tilt is smooth and im-

Tilt does not operate.

mediate.

13

SIDE SHIFT LEVER

Check that shift operates.

14

LIGHTS

Check that lights are working.

15

INSTRUMENT PANEL READINGS

Gauge registers less than 5 psi.

a. Oil pressure gauge-20 to 60 psi at normal

operating speeds.

Continuous high rate of charge

or discharge or erratic.

speed.

Registers in red portion of

c. Water temperature-170-210 after 10 minutes of

operation.

gauge.

F-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |