|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

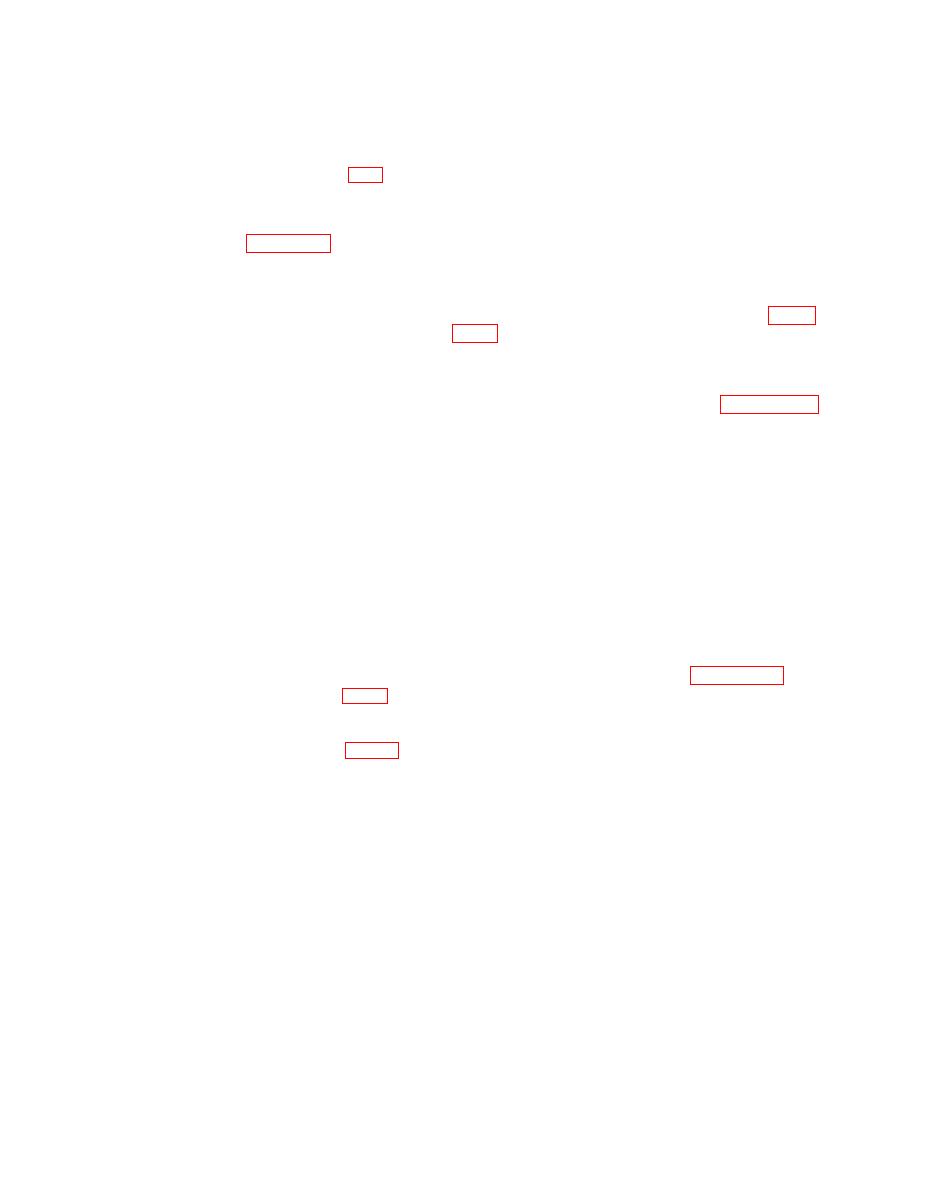

Legend for Figure 6-12

1.

Lower Dash P a n e l

7.

4.

Nut

Nut

8.

2.

Capscrew

5.

Lockwasher

Lockwasher

3.

Lockwasher

6.

Bracket

9.

Gauge

5 - 1 7 8 . GAUGE REMOVAL (Refer to Fig.

SEAT INSPECTION

5-181.

6-12 for Parts Identification).

a.

Inspect seat cushion and back

rest for cuts, tears, or similar

If any instrument gauges are found

Replace if necessary.

damage.

inoperative (Refer to page 3-4 for

g a u g e operation) remove gauge as

b . Inspect seat for loose or missing

follows:

c u s h i o n o r b r a c k r e s t f a s t e n e r s . Tighter

( R e f e r to page

R e m o v e battery ground cable.

or replace as necessary.

a.

7-95 for upholstery mounting fasteners.

b . R e m o v e lower dash panel fas-

Inspect seat adjustors for loose

C.

t e n e r s (Items 2 & 3) and remove

or missing fasteners. Tighten or re-

lower dash panel (Item 1) from

(refer to page 7-95

place as necessary.

machine.

for adjustor mounting fasteners.

C. R e m o v e gauge bracket fasteners

d . Inspect both seat adjustor mech-

( I t e m s 4 & 5) and bracket (Item 6)

from underside of dash.

anisms for free movement and full travel

Adjustors should travel a total of 4".

d . Remove terminal fasteners

Lubricate with MIL-L-10924 grease or

( I t e m s 7 & 8) and wires from term-

replace as necessary.

i n a l s . Lift gauge (Item 9) from

e.

Inspect adjusting lever on right

top of dash.

hand adjustor for free operation. Lub-

ricate if necessary with MIL-L-46152

5-179.

GAUGE INSTALLATION.

o i l . A l s o make sure adjustor locks

a.

Installation is the reverse of

securely into position when lever is

If not, replace entire ad-

removal as outlined in Section 5-178.

released.

justor assembly. (Refer to page 7-95

b . Refer to wiring diagram (page

f o r adjustor part numbers).

7-108) f o r c o r r e c t w i r e l o c a t i o n .

5-182.

SEAT INSTALLATION

5-180.

SEAT REMOVAL (Refer to Figure

Install the 2 rear seat mounting

a.

6-13)

bolts (1 eash of Items 2 & 3) through

t h e rear holes of seat adjustors. NOTE:

a . Raise seat support to full open

The longer bolts are used on the right

position.

hand adjustor to facilitate the in-

stallation of the heat shield (Item 6).

b . R e m o v e heat shield (Item 6)

b . With the seat support raised to

from underside of seat support by

the full open position, set seat on

r e m o v i n g 2 nuts, lockwashers, and

s e a t s u p p o r t , i n s e r t i n g the two mounting

w a s h e r s (Items 9, 8, & 7) from the

b o l t s through the two rear mounting hole:

1 right-hand seat adjustor mounting

in the seat support.

bolts (Item 3).

C.

I n s t a l l lockwashers and nuts

C. R e m o v e 4 seat adjustor mount-

(Items 4 & 5) on the two rear bolts.

ing bolts, lockwashers, and nuts

D O NOT tighten at this time.

( I t e m s 2, 3, 4, & 5). L i f t s e a t f r o m

machine.

5-208

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |