|

|||

|

|

|||

|

Page Title:

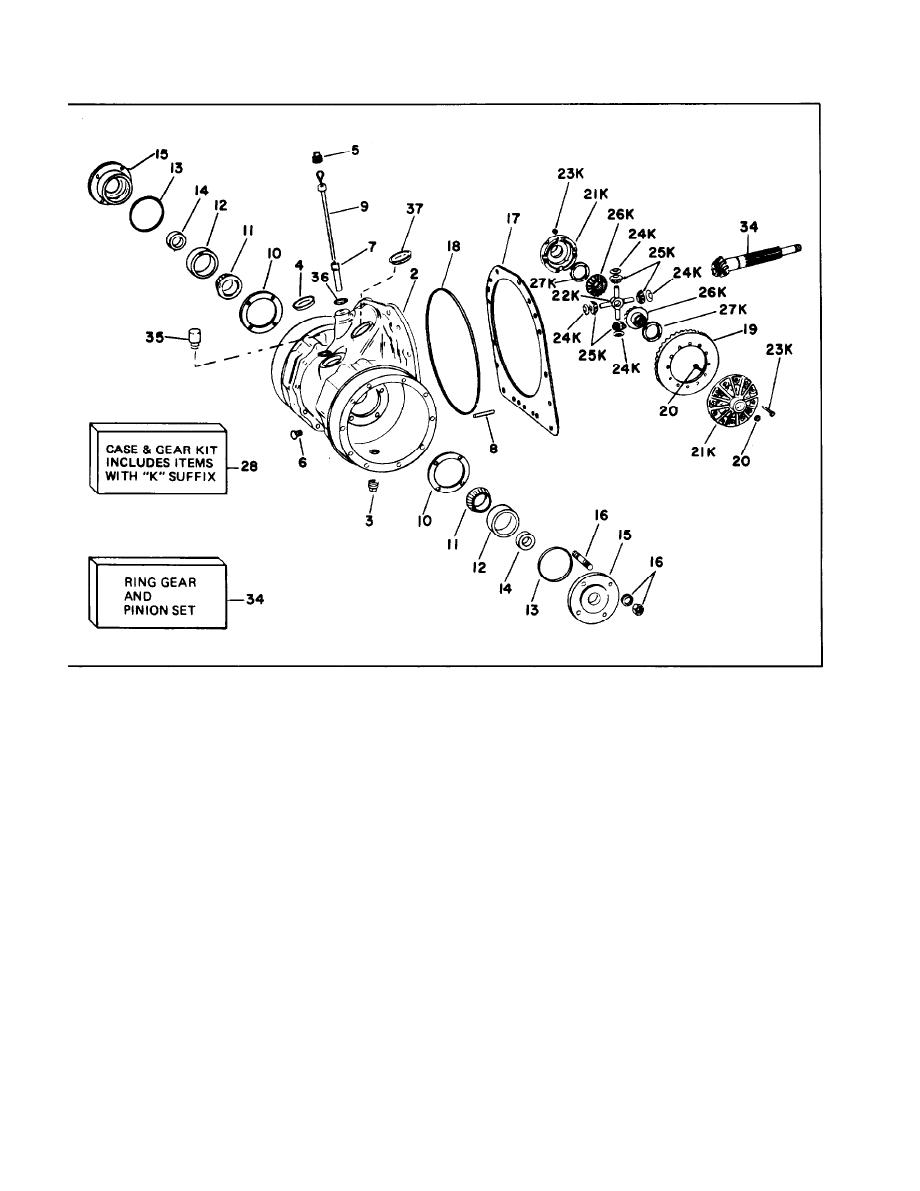

Figure 5-91. Axle Adapter and Differential |

|

||

| ||||||||||

|

|

9.

Dipstick

2.

Differential housing

Differential housing shim

17.

24.

Thrust washer

10.

Bearing carrier shim

3.

Drain plug

18.

Seal

Differential pinion gear

25.

4.

11.

Differential bearing cone

Inspection cover

19.

Ring gear

Differential side gear

26.

5.

Differential bearing

12.

Plug

Bolt, nut

20.

27.

Thrust washer

Bearing carrier seal cup

13.

6.

Plug

Bearing carrier seal

14.

Differential case

21.

34.

Ring gear, pinion set

Dipstick tube

7.

22.

Spider

35.

Vent

15.

Bearing carrier

8.

Dowel pin

23.

Case bolt

36.

Seal

16.

Nut, washer

37.

Access cover

Figure 5-91. Axle Adapter and Differential

d. Inspect all parts to detect cracks or fissures

c. Examine differential case, side gears, pinions

and thrust. washers for damage or excessive wear.

t o determine serviceability of parts. Surface of

Check clearance between pinions and pinion pin

spindle support which contacts oil seal lip must.

and thickness of all thrust washers. If differential

b e round, smooth finished and free from nicks,

scratches, grooves or scores.

side gears and pinions are worn or damaged,

a l w a y s replace with complete set - consisting of

e . Carefully inspect rollers, cages and cups for

four pinions, two side gears and all thrust

washers.

w e a r , chipping or nicks to determine fitness of

5-64

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |