|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

5-30. REPAIR.

a. Test valve spring pressure and length, using

spring tester as shown in figure 5-18. If springs do

n o t meet specifications of Table 5, replace with

new spring.

b . Check valve face runout as shown in figure

5-19. Face runout must not exceed specifications

of Table 5. If runout is excessive, valve must be

refaced or replaced.

c. Check valve seat runout, using an accurate gage

installed as shown in figure 5-20.

d. Place indicator point on face of seat, set

indicator at "0" and rotate the gauge set-up while

observing gage reading.

Figure 5-16. Valve Removal

e. If runout exceeds 0.002 inch above or below

"O", the seat must be refaced or replaced.

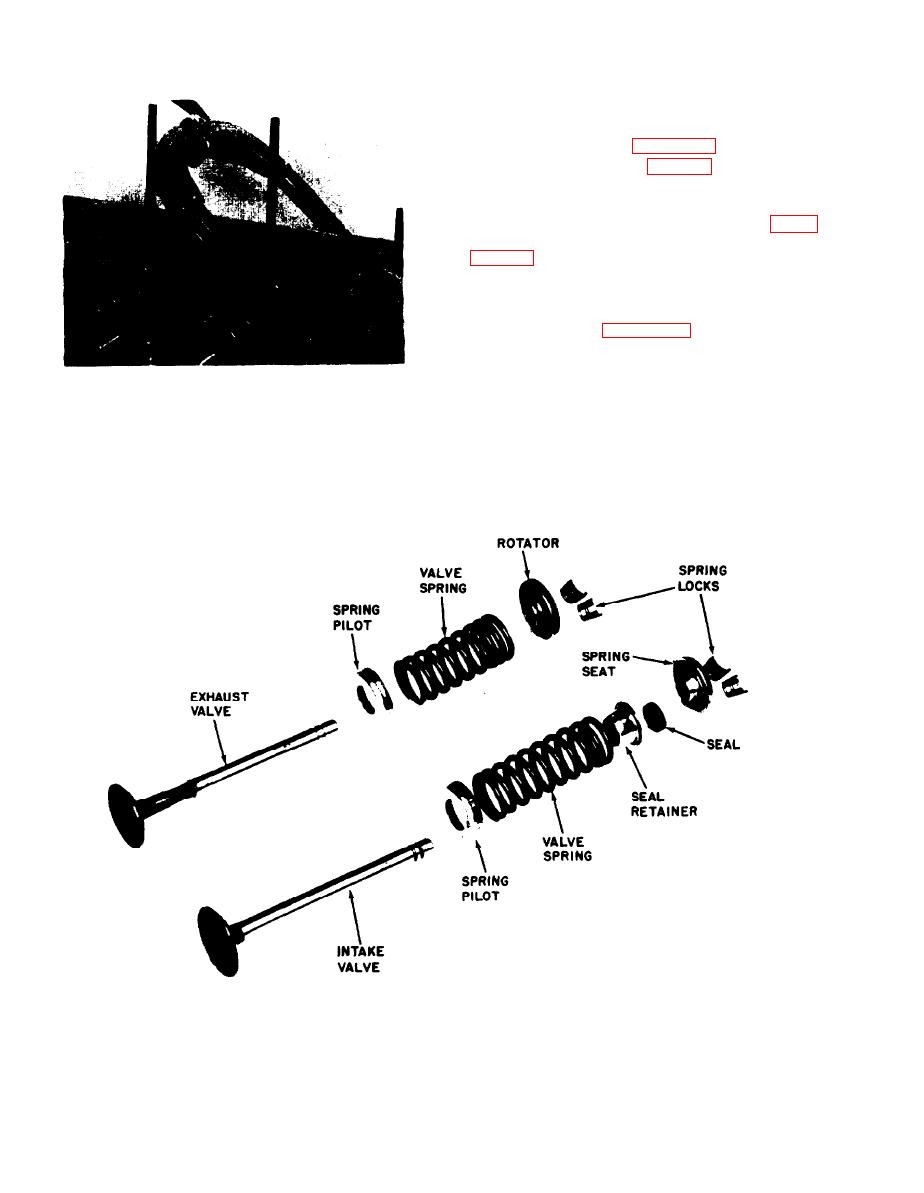

Figure 5-17. Value Parts Removed

5-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |