|

|||

|

|

|||

|

Page Title:

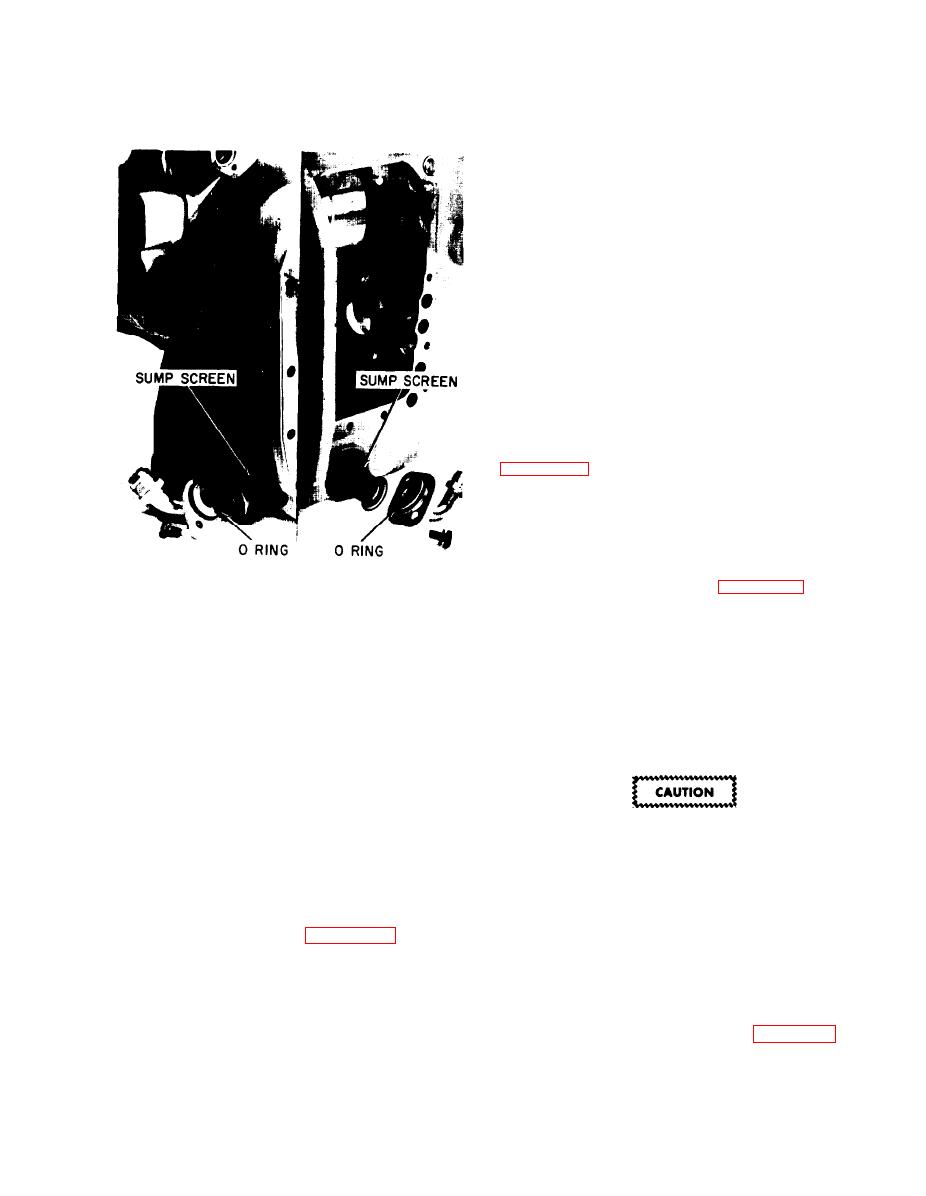

Figure 4-10. Sump Screen Removal |

|

||

| ||||||||||

|

|

1. Shut off the engine and check fluid level at

axle adapter dipstick, and add fluid as required t o

bring level to full mark.

4-10. HYDRAULIC SYSTEM. Under normal

service conditions the hydraulic sump should be

drained and the filter element changed after each

500 hours of operation. Severe service or adverse

conditions

will

operating

require

that

a

proportionately shorter interval be allowed

between services.

a. Lower carriage, and make certain that parking

brake is set. Shut engine off.

b . Remove cover plate to gain access to main

c o n t r o l valve pressure check point, as shown in

c. Remove pipe plug from the pressure check

p o i n t and connect a hose to the open port. The

hose should be of sufficient length to reach into a

10 gallon container placed on the floor to catch

the drained fluid, as shown in figure 4-13.

Figure 4-10. Sump Screen Removal

d. Place the free end of the hose into the

container and start the truck engine, allowing the

transmission/steering filter cartridge by unscrewing

engine to run at idle speed (500-550 RPM) while

from the filter base.

holding lift control lever back until the fluid

g. Clean off the filter base, and install a new filter

running from the hose starts to bubble and spurt,

cartridge. Lightly coat the new gasket (supplied

which indicates that the pump is beginning to draw

w i t h each cartridge) with a light film of clean

air. Shut off the engine immediately.

transmission fluid before installing.

h . Screw the cartridge down until gasket just

contacts base, and tighten l/2 turn more. Do not

overtighten.

Do not operate engine after the oil supply

t o the pump is exhausted. Running the

i. Change steering in-line filter (in pump suction

pump without adequate lubrication can

line) every 1000 hours.

result in serious damage to the pump.

j. Refill transmission through filler opening on

axle adapter, as shown in figure 4-12. Use only

e. Reinstall pipe plug in the pressure check point

Type "A", Suffix "A", Automatic Transmission

of main control valve.

F l u i d . (Containers must display a qualification

n u m b e r prefixed by "AQ-ATF".)

f. Place a flat pan of sufficient capacity under the

k. Operate engine at fast idle for approximately

sump tank drain plug as shown in figure 4-14. The

four minutes to distribute lubricant throughout the

pan should hold about 2 gallons.

system and expel trapped air.

4-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |