|

|||

|

|

|||

|

Page Title:

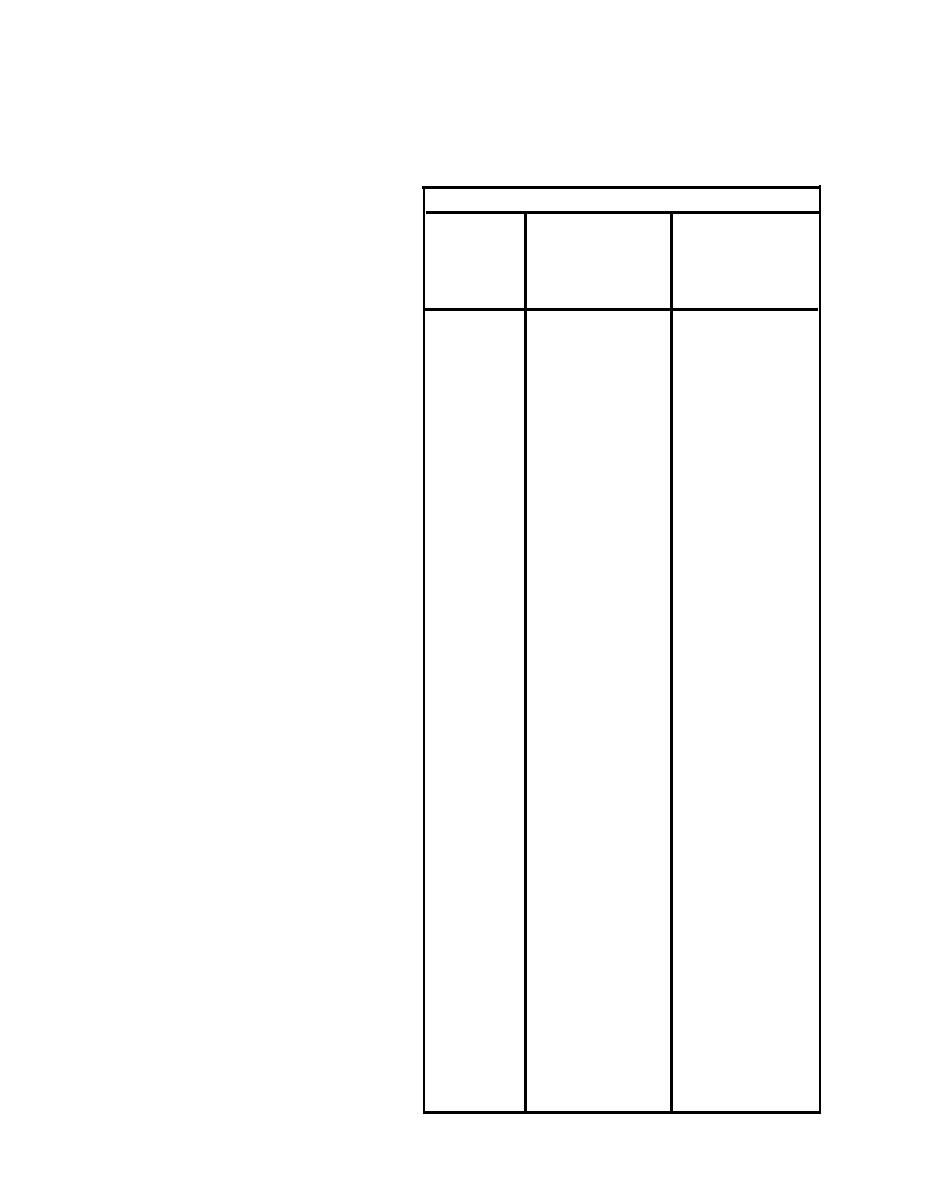

TABLE 3. PREVENTIVE MAINTENANCE INSPECTION - continued |

|

||

| ||||||||||

|

|

TABLE 3. PREVENTIVE MAINTENANCE INSPECTION (Continued)

I N S P E C T I O N INVERVAL

Annual,

3 months or 300

Daily,

or 1200

operating hours,

When

operating hours,

whichever

used

whichever

comes first

comes first

H Y D R A U L I C SYSTEM

Replace filter, inspect for proper operation

X

and leaks.

X

Check pump attaching bolts.

X

Check lines for damage and leaks.

X

Check oil level. Add oil if necessary.

X

Drain and refill.

Check all fittings and connections. Tighten if

X

necessary.

Check operation of hydraulic valves and

X

cylinders. Check for leakage.

TRANSMISSION/CONVERTER

Check oil level. (Must be done with engine

X

running or immediately after)

X

Check for oil leaks at lines, fittings, and gaskets.

Check converter pump pressures (both converter

X

charging and transmission clutch pressure).

X

Drain oil and refill.

X

Remove and clean sump screen.

WHEELS AND TIRES

X

Check tires for cuts or foreign objects.

X

Check hub bolt nuts.

X

Check bearings for looseness.

X

Check oil seals.

X

Cross-switch tires, if uneven tread is noted.

X

race for defects.

U P R I G H T AND CARRIAGE

X

Bleed lift cylinder.

X

Check lift chain adjustment.

X

Adjust roller clearances.

Check for damage or warped

X

upright rails on carriage.

X

Check forks for damage.

X

Check cylinders for leakage.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |