|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14 &p

5. Reconnect hydraulic hoses to cylinder.

7. Lubricate all pressure lube fittings on side shifter

unit.

6. Reinstall lower hanger bars. Torque capscrews

to required value; see tabulation below.

D. ADJUSTMENT

Refer to appropriate Topic for the adjustment of the type

CAPSCREW SIZE

TORQUE VALUE

carriage used.

NOTE

If carriage frame is of the canted

.33"-16 x 1.25"

28-33 lb. ft.

bearing type it must be adjusted

before installation.

.38"-16 x 1.50"

28-33 lb. ft.

.50"-13 x 1.50"

G8-73 lb. ft.

.63"-11 x 1.75"

125-135 lb. ft.

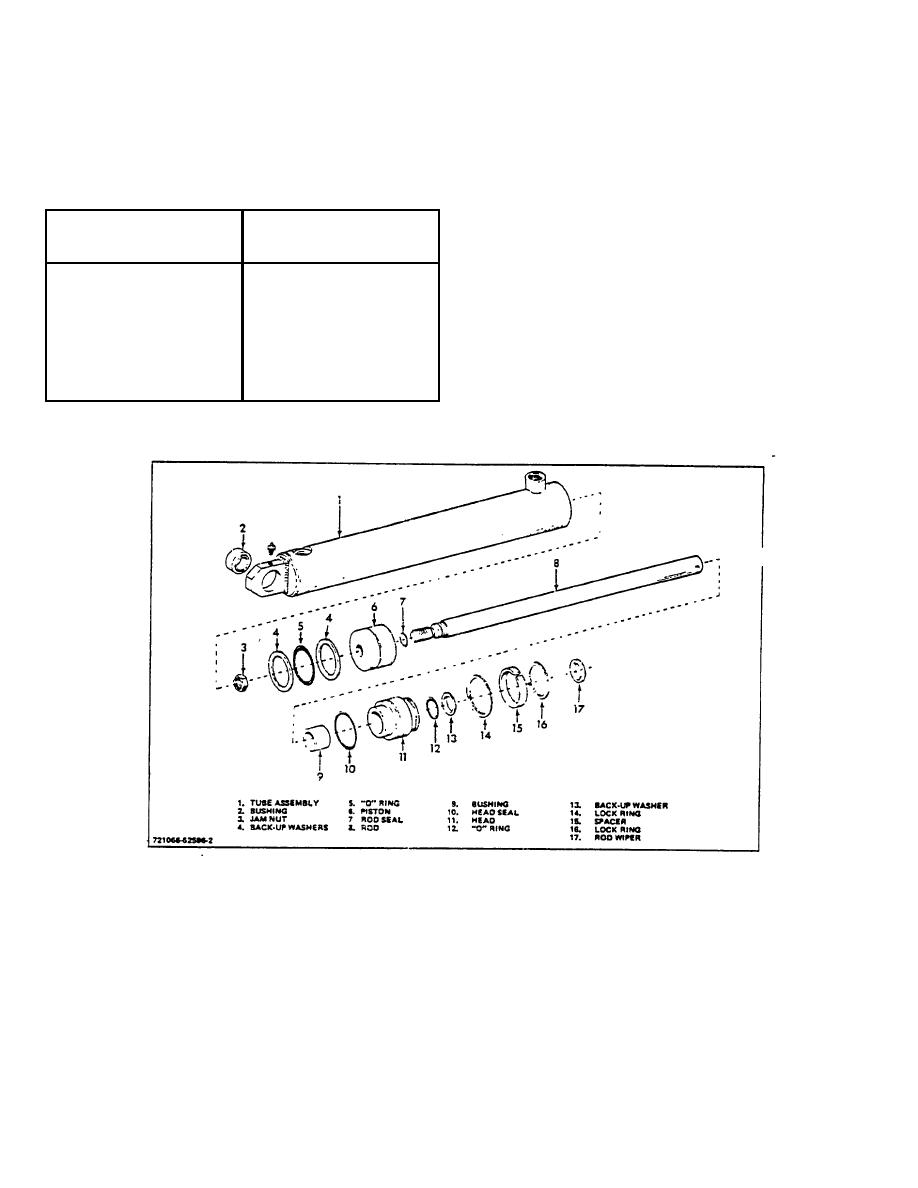

TOPIC 6. SIDE SHIFTER CYLINDER

Figure 8.

A. REMOVAL

3. Disconnect hydraulic hoses from cylinder. Plug

cylinder ports and hydraulic hose ends to

1. Remove cotter pin and rod pin from cylinder rod.

prevent entry of foreign material.

2. Retract cylinder rod far enough to clear rod

4. Remove cotter pin and cylinder retainer pin and

retainer on side shift plate.

lift out cylinder.

3-202

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |