|

|||

|

|

|||

|

Page Title:

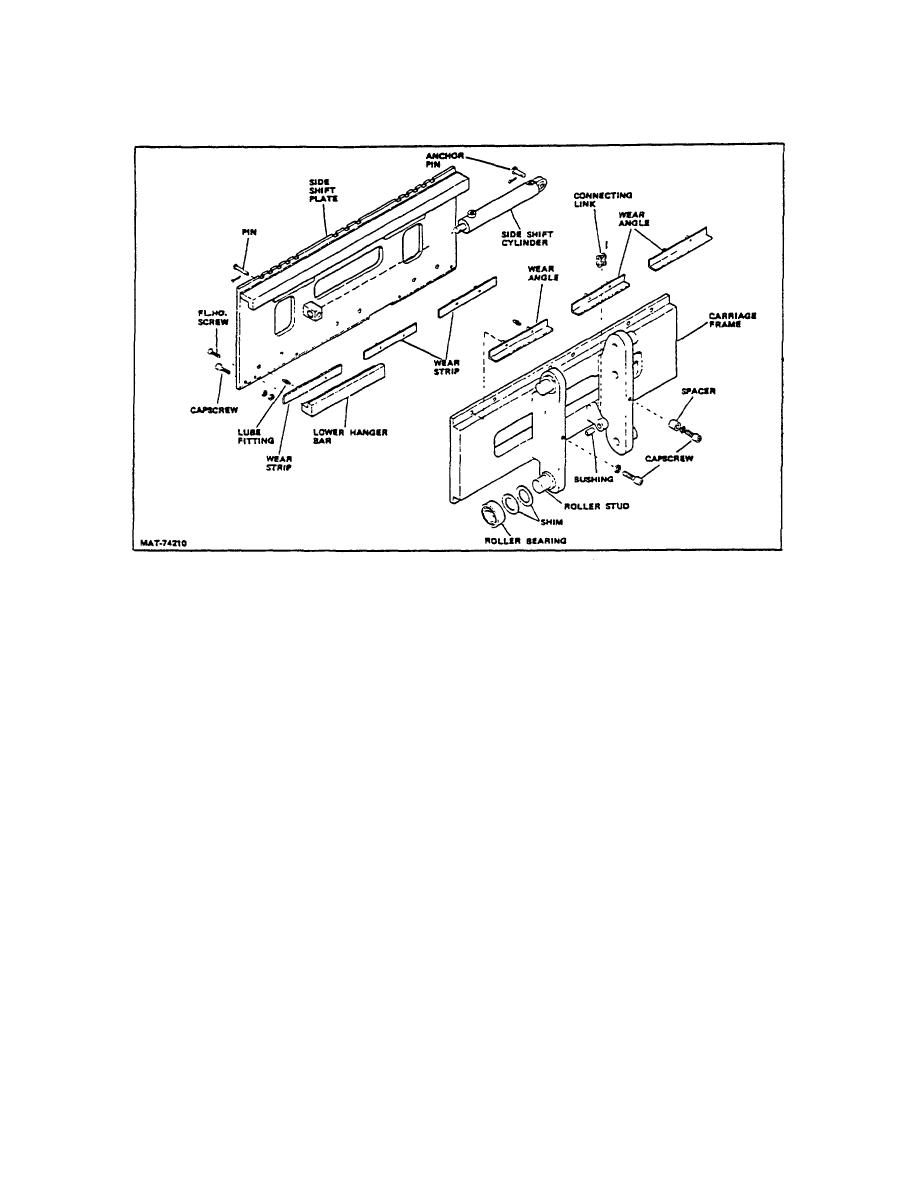

Figure 7. Side Shifter Components (Typical) |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 5 SIDE SHIFTERS

Figure 7. Side Shifter Components (Typical)

A. REMOVAL/INSTALLATION

6. Pry off wear strips at bottom of side shift and top

of carriage plates. Wear strips and wear angles

First disconnect hydraulic hoses at junction block on

should be replaced when worn to a thickness of

carriage frame, then refer to TOPIC I and perform the

.063".

appropriate removal (or installation) procedures.

7. Check all wear strip and wear angle mating

surfaces for nicks, foreign material or any high

B. DISASSEMBLY

spots. Repair or replace as necessary.

C. REASSEMBLY

NOTE

For disassembly of the carriage

1. Reinstall wear strips and wear angles by

frame refer to the appropriate topic

snapping into holes provided. Lubricate all wear

depending on the type carriage used.

strips and angles with a light coat of a Grade 2

1. To disassemble side shifter, first disconnect and

lithium base grease, (characterized by the word

plug the hydraulic hoses from the side shift

"Moly").

cylinder, to prevent entry of foreign particles.

2. Using a suitable hoist, lift side shift plate to

2. Disconnect side shift cylinder from side shift

relative mounting position at right side of

plate by removing retaining pin and cotter pin.

carriage frame (when facing carriage).

3. Attach a suitable hoist to side shift plate and

3. Carefully slide side shift plate onto carriage

take up slack in chain.

frame.

4. Slide side shift plate off right side of carriage

4. Reconnect side shift cylinder plunger to side

frame (when facing the carriage), and move/to

shift plate by reinstalling retaining pin and cotter

desired location.

pin.

5. remove lower hanger bars.

3-201

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |