|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

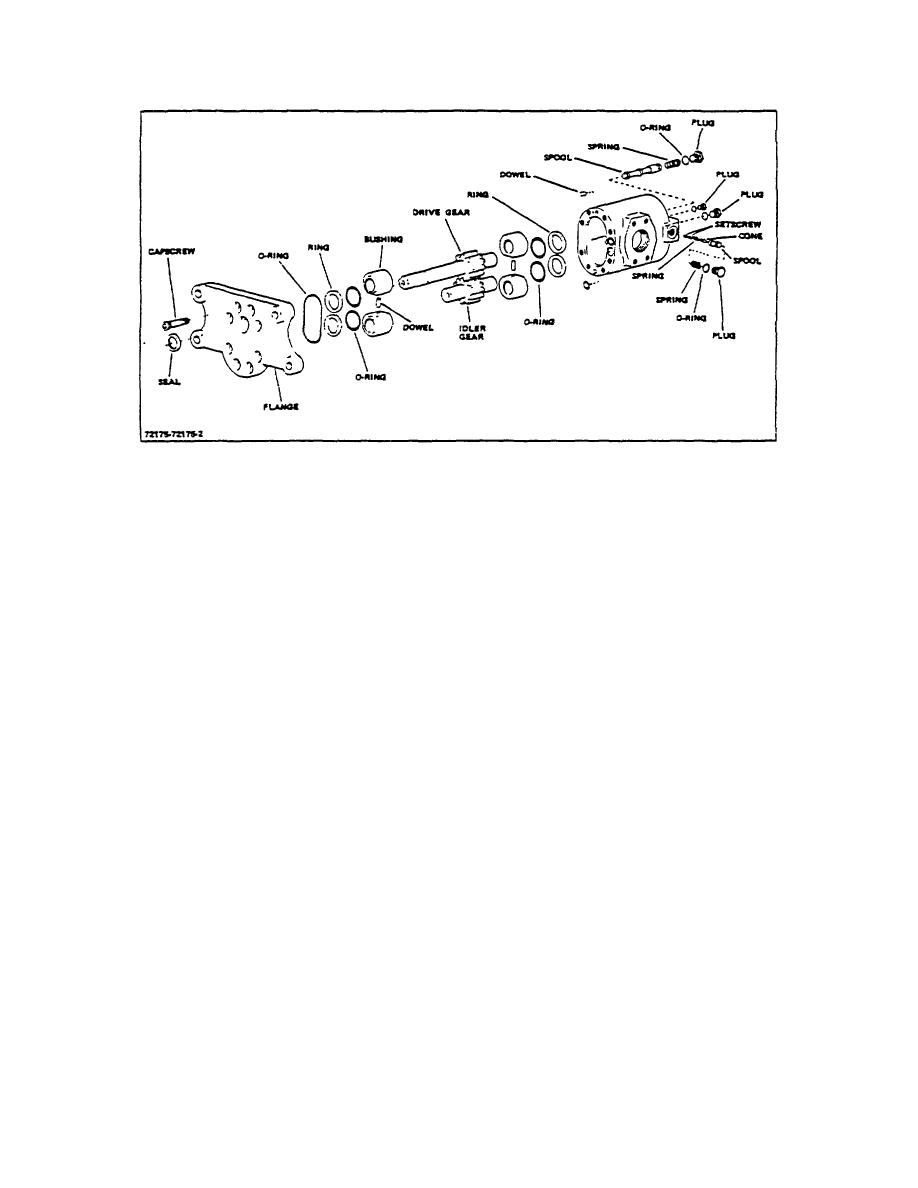

Figure 1-1. Hydraulic Pump

Looking at the plate from the pump side,

body. Check diameter of all lands and replace

measure the top left and lower right mounting

spool if any are less than .748. Check the

holes. If the holes are larger than .441 diameter,

balance and flow orifices and clear with a fine

replace the flange. This indicates pump has

wire, if plugged.

been running with mounting bolts loose.

if

flange is to be reused, hone same as body face.

7. Check valve spool spring to see that it is not

bent or deformed. Replace if length is less than

4. Handle pump gears carefully when inspecting to

3-1/2'".

prevent burring the teeth with resultant damage

to the bushings. If the length of the gear is less

8. Inspect the relief valve plunger for wear and

than 1.320, or if gear O.D. is less than 1.754,

erosion and replace, if damaged.

the gear must be replaced. Check gear teeth

ends and remove any burrs with a small, fine

9. If relief valve spring is bent or deformed, replace

hone. If journal surfaces are blackened, and

it. Replace if length is less than 0.30.

can be scratched with a pen knife, they have lost

their case hardening and must be replaced.

E. REASSEMBLY

5. When inspecting the bushings, they must be

Before reassembling pump, lay out all parts in a

handled very carefully to prevent damage, as

sequence in which they were removed and make sure all

this makes them difficult to assemble and

parts are perfectly clean.

reduces their sealing effectiveness. The bore of

the bushing, will be worn slightly oval, must not

1. Place pump face up and install the two body

measure over 0.381 at the largest reading. The

dowels, tapping them in place with a plastic

length of the bushing must not measure under

hammer. Coat body bores with light oil.

1.055. Minor cuts or scratches can be removed

by honing in a circular motion with an extra fine

2. Place the bushing O rings and the backup rings

stone. Be sure sharp edge between face of

on the shoulder at the rear of the rear bushings.

bushing and the O.D. is not broken. Erosion on

Hold in place with grease, if necessary. Place

the face of the bushing near the rectangular land

the bushing dowel in the holes in the flat side of

and in the lube oil slot indicates dirt in the

the bushings and holding the bushings together,

system.

carefully align then and slide them, O Ring side

down, into the bores. Coat faces and bores of

6. Wash valve spool and dry with compressed air.

the bushings

It should slide freely in and out of its bore in the

3-180

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |