|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

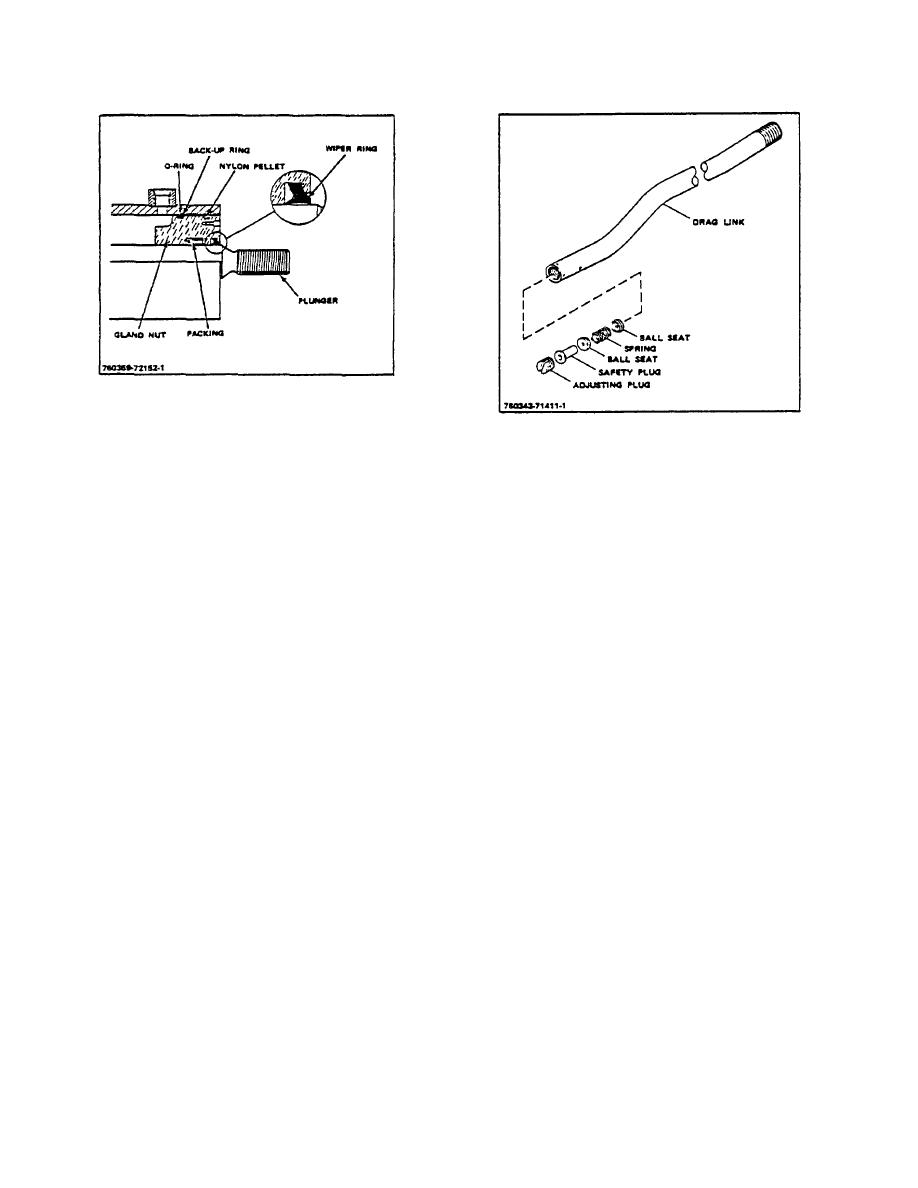

Figure 31. Cylinder Assembly

b. Usually no adjustment is required upon

Figure 32. Drag Link Components

installation; make certain that O-rings are

not twisted.

E. DRAG LINK DISASSEMBLY

c. Check to see that the ring is of correct

1. Remove adjusting plug, safety plug, ball seats

size to give a "squeeze" in the installed

and spring from drag link tube (Fig 32).

position.

2. Clean all parts in a suitable solvent. Be certain

11. Do everything possible to keep all hydraulic

all dirt and contaminants are removed.

parts as clean as possible. Keep dirt and fine

metal particles from packing and plungers.

3. Inspect all parts for cracks, nicks or other

Such material can quickly damage packing and

damage. Replace any parts that are worn or

score plungers.

damaged.

12. Inspect bushing and lube fitting in anchor pivot

F. DRAG LINK REASSEMBLY

assembly. Replace any damaged or worn parts.

Install one ball seat then the spring and the second ball

D. CYLINDER REASSEMBLY

seat followed by the safety plum and adjusting plug in

the end of the drag link tube.

Reverse disassembly procedure when installing new

parts.

G. INSTALLATION

1. Install new packing and bearing on piston.

1. Place steering cylinder into position on truck and

secure to mounting anchor with anchor pin,

2. Install spacers on plunger rod. Be sure that

washer, and cotter pin. Cylinder should pivot

outer spacer has an O-ring in groove.

freely in anchor.

3. Install piston and plunger assembly in cylinder

2. First make certain locknut is on drag link and

tube.

connect drag link to steering cylinder by

screwing drag link into cylinder tube.

4. Install new nylon pellets, O-ring, back-up ring,

packing and wiper on paking gland nut.

3. Connect drag link to pivot arm, screw in

adjusting plug, and secure with cotter pin.

5. Install packing gland nut on plunger assembly

and cylinder tube. Gland nut must be flush with

4. Remove plugs and connect hoses to power

outer edge of cylinder tube.

steering cylinder.

6. Install adjusting spacer, jam nuts, and anchor

5. Make sure hoist is securely attached to

pivot assembly on plunger rod.

3-173

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |