|

|||

|

|

|||

|

Page Title:

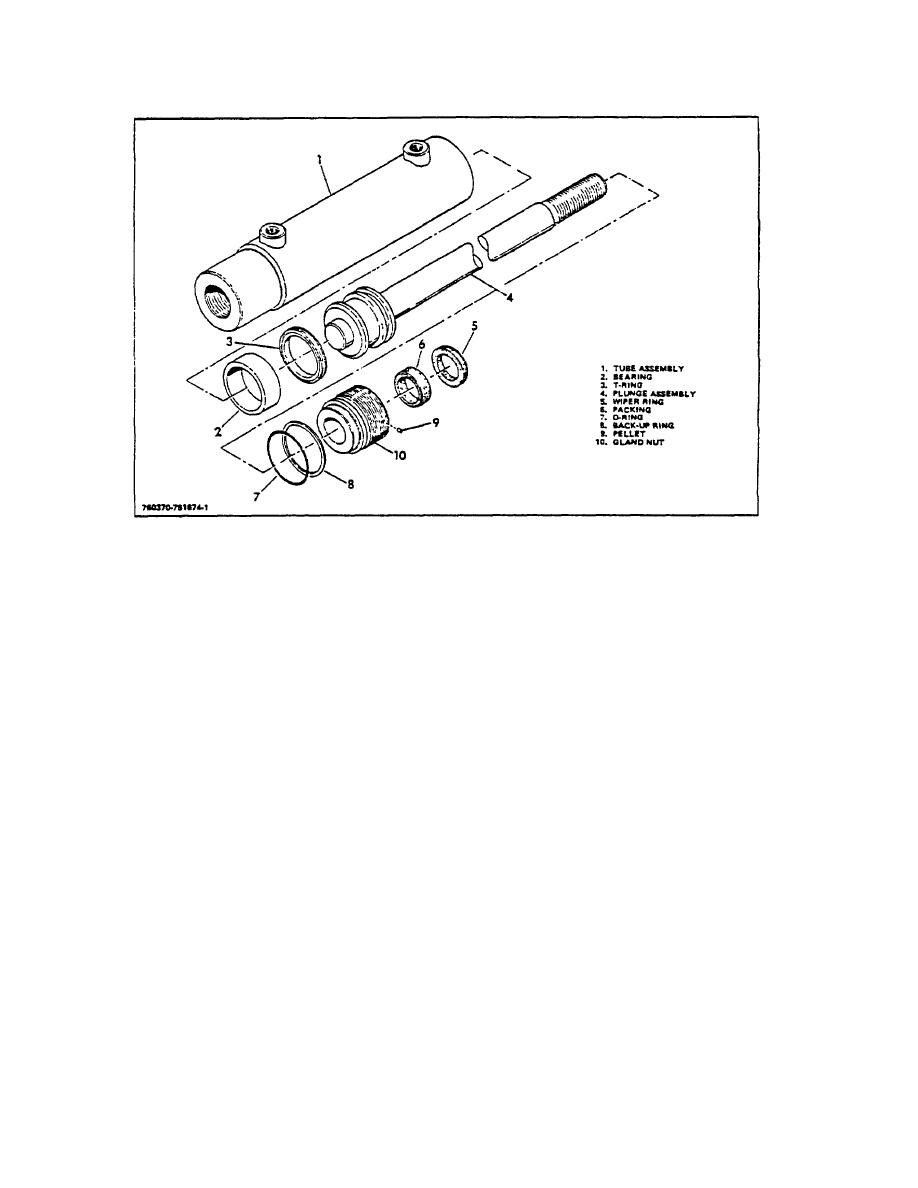

Figure 30. Power Steering Cylinder Components |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Figure 30. Power Steering Cylinder Components

lubricate with hydraulic oil and do not

3. Use only approved packing.

Never make

overstretch when sliding over edge of packing

substitutions.

gland.

4. Before installing, inspect for nicks, cuts or flaws.

4. When replacing plunger packing seal, remove

Do not install If any of these faults are present.

items in Steps 1 and 2 in this paragraph, and

then withdraw complete piston and plunger

5. All metal surfaces on which packing slides

assembly from cylinder tube.

should be very smooth. If surfaces are scored

or nicked, replace the parts or resurface them.

CAUTION

6. Soak packing in hydraulic oil before installing.

Do not attempt to remove piston from

plunger rod. They do not separate.

7. Sharp tools or Instruments should not be used

5. Remove bearing and packing from piston.

when Installing packing.

6. Thoroughly check cylinder bore for score marks

8. When installing seal rings do not stretch them

or nicks.

These cause damage to piston

more than absolutely necessary.

packing cups.

9. Fit packing evenly and snugly without using

C. CYLINDER REPAIR

undue force.

1. When packing starts to wear, renew it, otherwise

10. When packing must be installed over threads or

parts of the packing will contaminate the oil and

sharp edges, use shim stock to protect packing.

work into the pump or valve, thus causing

damage, or malfunction.

a. O-rings should be pushed over sharp

edges with care. They can be easily cut.

2. Do not disassemble the unit any more than is

required to replace the faulty packing.

3-172

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |