|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

7. Fill seal with grease and install it on pivot arm

pin.

8. Install washer and start new nut on pivot arm

pin.

9. Use a torque wrench and continue to tighten nut.

Note torque reading while advancing lower cone

to its seated position.

You will notice an

increase in the torque when the lower cone

starts to seat. Continue to tighten nut until

torque is 15-25 lb-ft greater than previously

noted before lower cone started to seat.

10. Check rotational bearing torque. Rotate pivot

arm back and forth several times and take rolling

torque reading. It should require 15-25 lb-ft

torque to rotate pivot arm in either direction.

NOTE

Tie rods must not be connected to

pivot am whenever rolling torque is

checked.

11. If rolling torque is less than 15 lb-in, tighten nut

an additional 5 lb-ft torque and repeat Step 10.

12. If rolling torque exceeds 25 lb-in, back nut off

one full turn. Strike end of pivot arm pin with a

softheaded mallet to unseat bearings and repeat

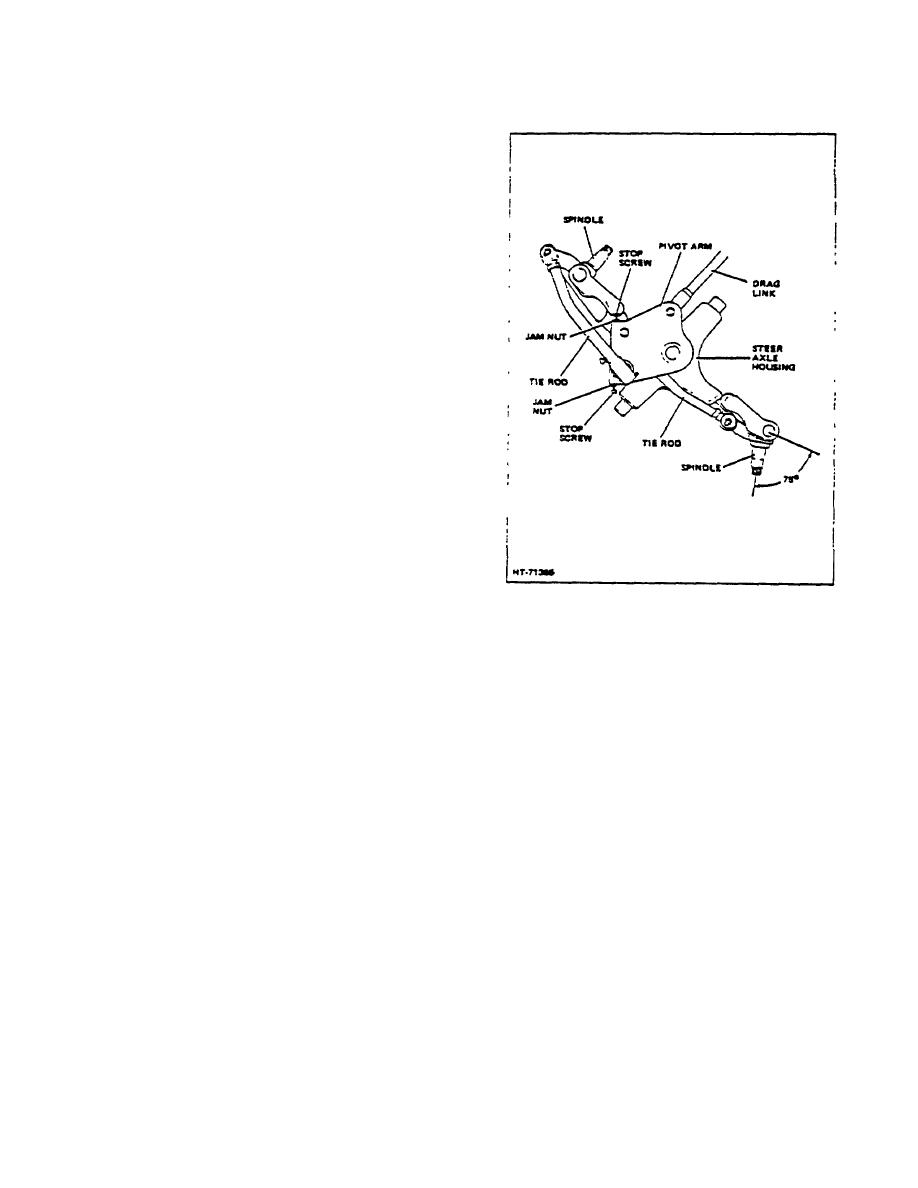

Figure 5. Pivot Arm Stop Adjustment

Steps 9 and 10.

turn and then to full left turn and adjust pivot arm

13. After proper rolling torque is obtained, stake end

stop screw each time.

of nut approximately .030" deep into slot (Fig. 4).

2. Loosen Jam nuts and adjust the pivot arm stops

14. Fill cavity with specified grease until it seeps out

(Fig. 5) to allow 1/2" clearance between the

between pivot am and steer axle housing.

steer wheel and steer axle housing with the

wheels turned full right or full left. Stops should

G. PIVOT ARM STOP ADJUSTMENT

limit travel of wheel spindle to 75 from

centerline of spindle. Tighten stop screw jam

1. Turn steer wheels first to full right

nut to a torque of 2 to 3 lb-ft.

3-162

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |