|

|||

|

|

|||

|

Page Title:

DRIVE UNIT DISASSEMBLY/REASSEMBLY |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

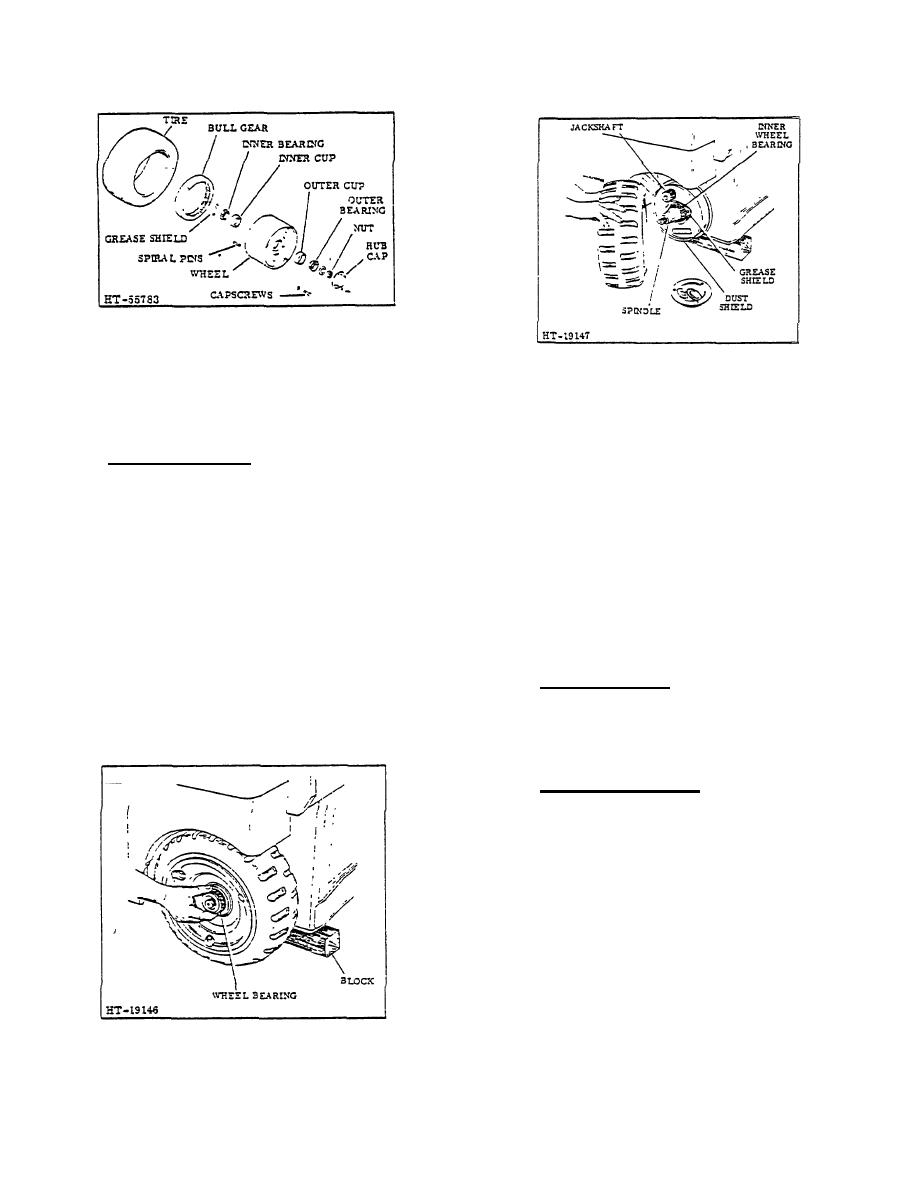

Figure 4. Drive Wheel Assembly

C. DRIVE UNIT DISASSEMBLY/REASSEMBLY

Figure 6. Removing Drive Wheel

The following operations may be performed without

and retaining nut.

The outer wheel

removing the drive unit from the truck.

bearing can now be removed.

1. Drive Wheel Removal

c. After the outer wheel bearing has been

removed, the wheel can be removed.

The wheel assembly consists of the wheel, tire.

(See Figure 6.)

brake drum. wheel bearings and the bull gear.

(Figure 4.)

CAUTION

When removing wheel, exercise care

To remove the wheel:

so that no damage to the drum or

brake shoes occurs.

a. Raise the truck sufficiently so that the

drive wheel clears the floor. This may be

d. After the drive wheel has been removed,

done by tilting the mast to Its full backward

the inner wheel bearing and the grease

position and inserting a block under the

shield can be removed.

mast assembly, then tilting mast to its

vertical position. (See Figure 5.)

2. Inspection - Service

b. Remove capscrews, lockwashers and hub

Using a solvent, wash all grease from the bearings and

cap. Remove cotter pin, washer

bearing surfaces. Inspect for worn or damaged parts

and replace where necessary.

a. Replacing Bearing Cups

(1) Recesses are provided on the inner hub of

the drum; insert a brass drift at these

points, tap lightly with a hammer and

remove cup.

(2) When replacing bearing cups, set in hub

with taper to the outside of the wheel.

Using a brass drift, tap evenly around the

edge of the cup, exercising care so that

;he cup will not bind (bearing press can

also be used for installation).'

NOTE

Bearing cup should be a press fit.

Figure 5. Removing Wheel Bearing

3-137

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |