|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

Selector Valve

At periodic inspections, make sure all mounting

Forward (F) position permits oil to flow to the forward

capscrews are tight. Make certain no oil is leaking past

clutch and exhaust reverse clutch. Neutral (N) position

the output shaft and that the universal joints are tightly

permits the selector valve to block oil at the valve and

connected.

to flow to reverse clutch and exhaust forward clutch.

C. REMOVAL

Converter Regulator Valve

When it becomes necessary to remove the transmission

Oil fed to converter from pressure regulator valve is

and/or converter for repair, the following procedure is

directed to end of converter regulator valve. Any time

recommended.

force from oil on the end of the valve exceeds spring

force, the valve opens to feed oil to lube and clutch

1. Remove the floor and toe plates, seat deck

cooling circuit.

assembly, front screen and air filter.

Clutch Orifice and Flyball

2. Drain oil from transmission by removing drain

Clutch cylinders or pistons are provided with either bleed

plug at rear of sump.

holes or bleed holes and ball dump valve. These are

provided to exhaust oil from the clutch cylinder and

3. Disconnect the cooler lines at the bottom and at

assure clutch release. Centrifugal force could cause

the right side of the sump. Cap lines and plug

pressure buildup within the clutch cylinder if bleeds were

holes to avoid contaminating system.

not provided. The flyball bleed provides fast release and

permits higher apply pressure.

4. Remove all control linkage.

Disconnect wires

from neutral start switch.

B. SERVICE

At the truck lubrication period, open trap door in floor

5. Disconnect the

universal

joints

at

the

plate and check the oil level of the transmission sump by

transmission.

use of the dipstick. Engine must be running for this

check. Add automatic transmission fluid, if necessary, to

6. Remove the capscrews and lockwashers which

bring the oil level up to the FULL mark on the dipstick.

mount the converter to the flywheel through the

When so noted (every 1000 hours of operation), the

flywheel inspection hole. Use a suitable tool to

transmission sump should be drained and refilled with

rotate the flywheel

new oil.

NOTE

CAUTION

The convertor flex plate mounts the

DO NOT OVERFILL TRANSMISSION.

engine timing mark decal.

The

relationship between the flex plate

No specific time intervals are given, but the shift control

and flywheel should-he marked prior

adjustment should be checked on occasion.

to convertor removal.

The transmission operating pressures should be

checked whenever the unit is not operating efficiently or

after any internal parts have h in replaced. Make certain

the oil cooler lines are tight. Refer to CHECK OUT

PROCEDURES

(TOPIC

2,

TRANSMISSION

MAINTENANCE MANUAL).

Check and adjust the

shifting mechanism if necessary. Refer to TOPIC 3,

TRANSMISSION MAINTENANCE MANUAL.

To check and service transmission oil cooler, refer to

TOPIC 4, TRANSMISSION MAINTENANCE MANUAL.

To service the oil filter, refer to TOPIC

5,

TRANSMISSION MAINTENANCE MANUAL.

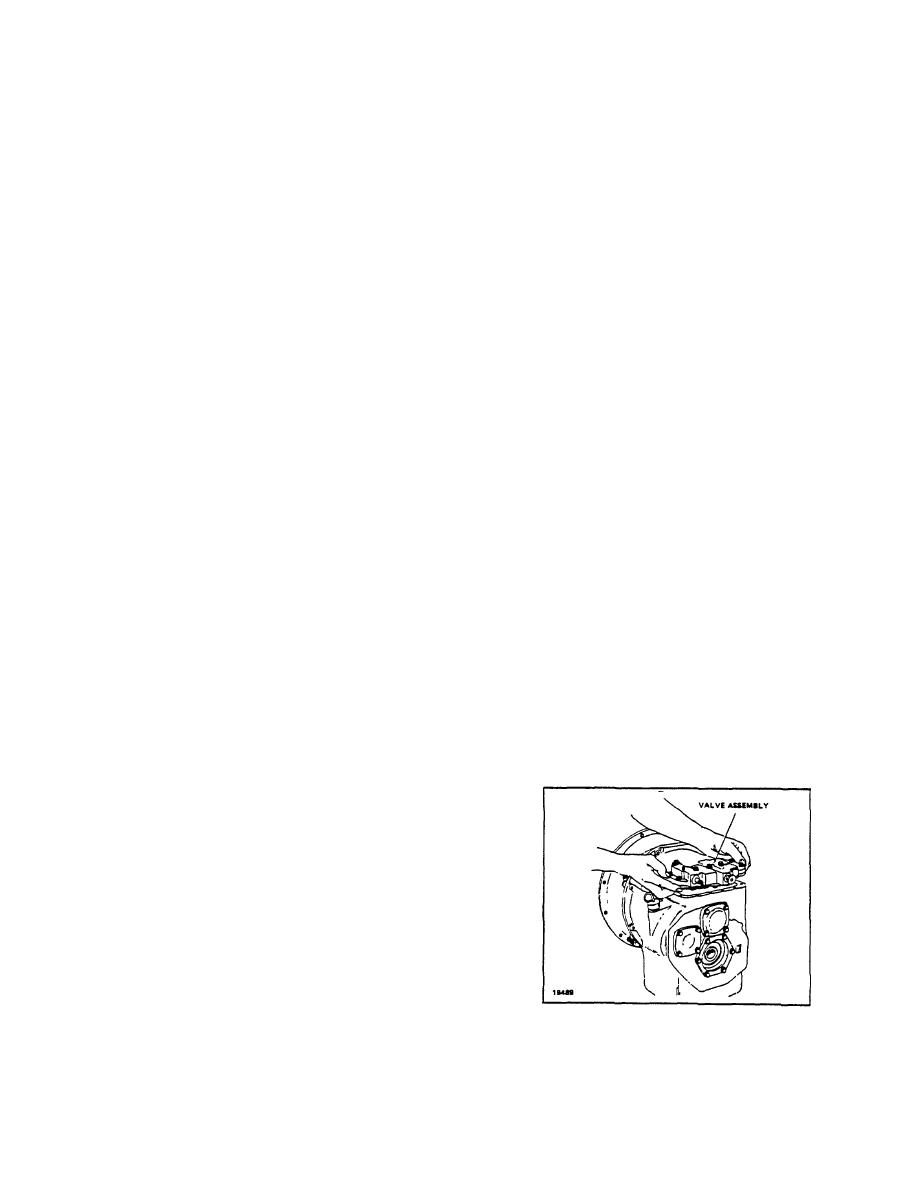

Figure 1-3. Removing Valve Block

R-171-1

3-118

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |