|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14 & P

6. Brush Holder and Regulator Replacement.

CAUTION

Do not use high voltage to check

After removing the three attaching nuts, the

these units, such as a 110 volt test

stator, and diode trio screw (Figs. 2-9 and 2-10),

lamp.

the brush holder and regulator may be replaced

To replace the rectifier bridge, remove the

by removing the two remaining screws. Note

attaching screws, and disconnect the capacitor

the two insulators located over the top of brush

lead. Note the insulator between the insulated

clips in Figure 2-6; these two screws have

heat sink and end frame (Fig. 2-9). Rectifier

special insulating sleeves over the screw body

bridges may vary in appearance but are

above the threads. The third mounting screw

completely interchangeable in these generators.

may or may not have an insulating sleeve. If

not, this screw must not be interchanged with

5. Stator Checks

either one of the other two screws, as a ground

may result, causing no output or uncontrolled

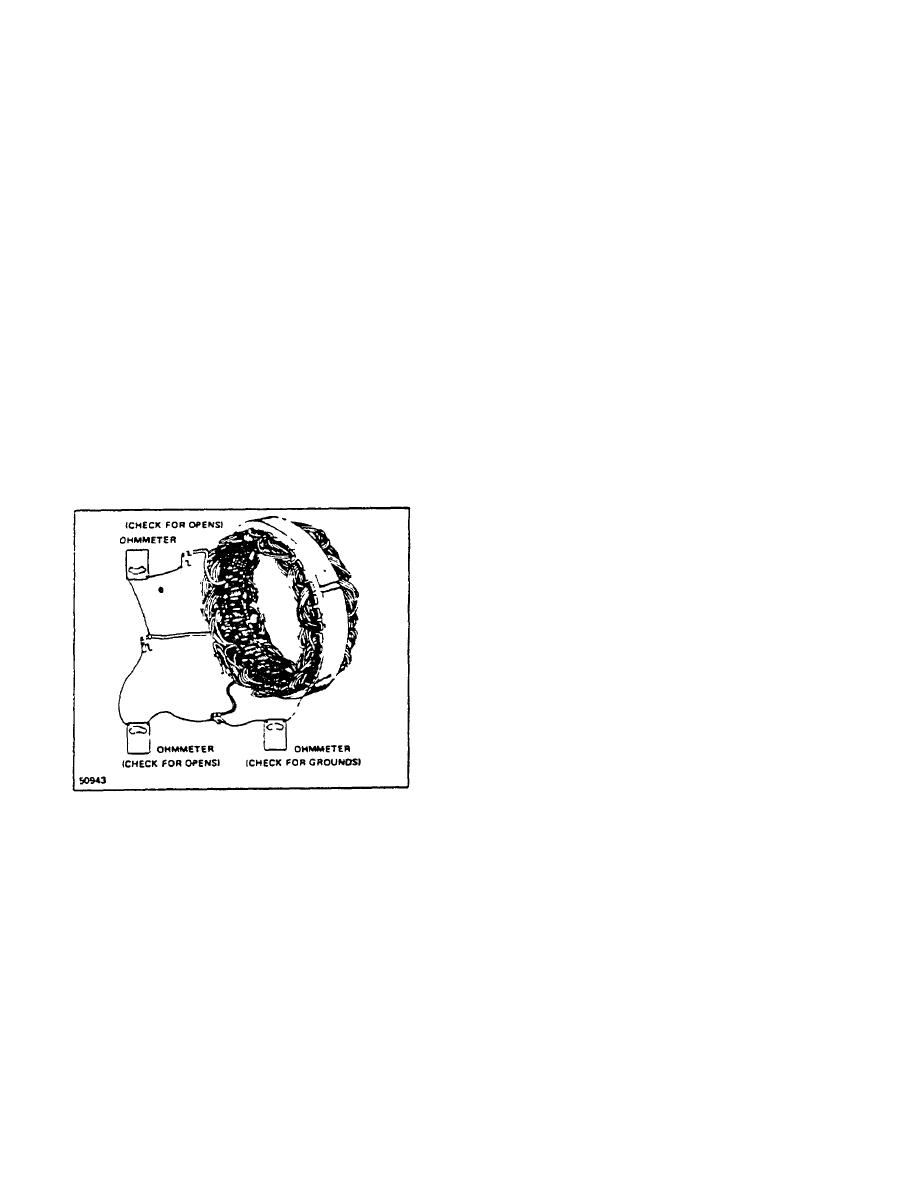

The stator windings may be checked with a 110

generator output.

Regulators may vary in

volt test lamp, or with an ohmmeter. If the lamp

appearance but are completely interchangeable.

lights, or if the meter reading is low when

connected from any stator lead to the frame, the

7. Slip Ring Servicing

windings are grounded. If the lamp fails to light,

or if the meter reading is high when successively

If the slip rings are dirty, they may be cleaned

connected between each pair of stator leads, the

and finished with 400 grain or finer polishing

windings are open (Fig. 2-11).

cloth. Spin the rotor, and hold the polishing

cloth against the slip rings until they are clean.

CAUTION

The rotor must be rotated in order to

clean the slip rings evenly.

Cleaning the slip rings by hand

without spinning the rotor may result

in flat spots on the slip rings, causing

brush noise.

Slip rings which are rough or out of round should

be trued in a lathe to .002" maximum indicator

reading. Remove only enough material to make

the rings smooth and round. Finish with 400

grain or finer polishing cloth and blow away all

dust.

8. Bearing Replacement and Lubrication

Figure 2-11. Checking Stator Windings

The bearing in the drive end frame can be

removed by detaching the retainer plate screws,

A short circuit in the stator windings is difficult to

and then pressing the bearing from the end

locate without laboratory test equipment due to

frame. If the bearing is in satisfactory condition,

the low resistance of the windings. However, if

it may be reused, and it should be filled one-

all other electrical checks are normal and the

quarter full with Delco-Remy lubricant No.

alternator fails to supply rated output, shorted

1948791 before reassembly.

stator windings Are indicated

CAUTION

Do not overfill bearing as this may

cause it to overheat.

Use only

1948791 lubricant.

R-146-1

3-88

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |