|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14 & P

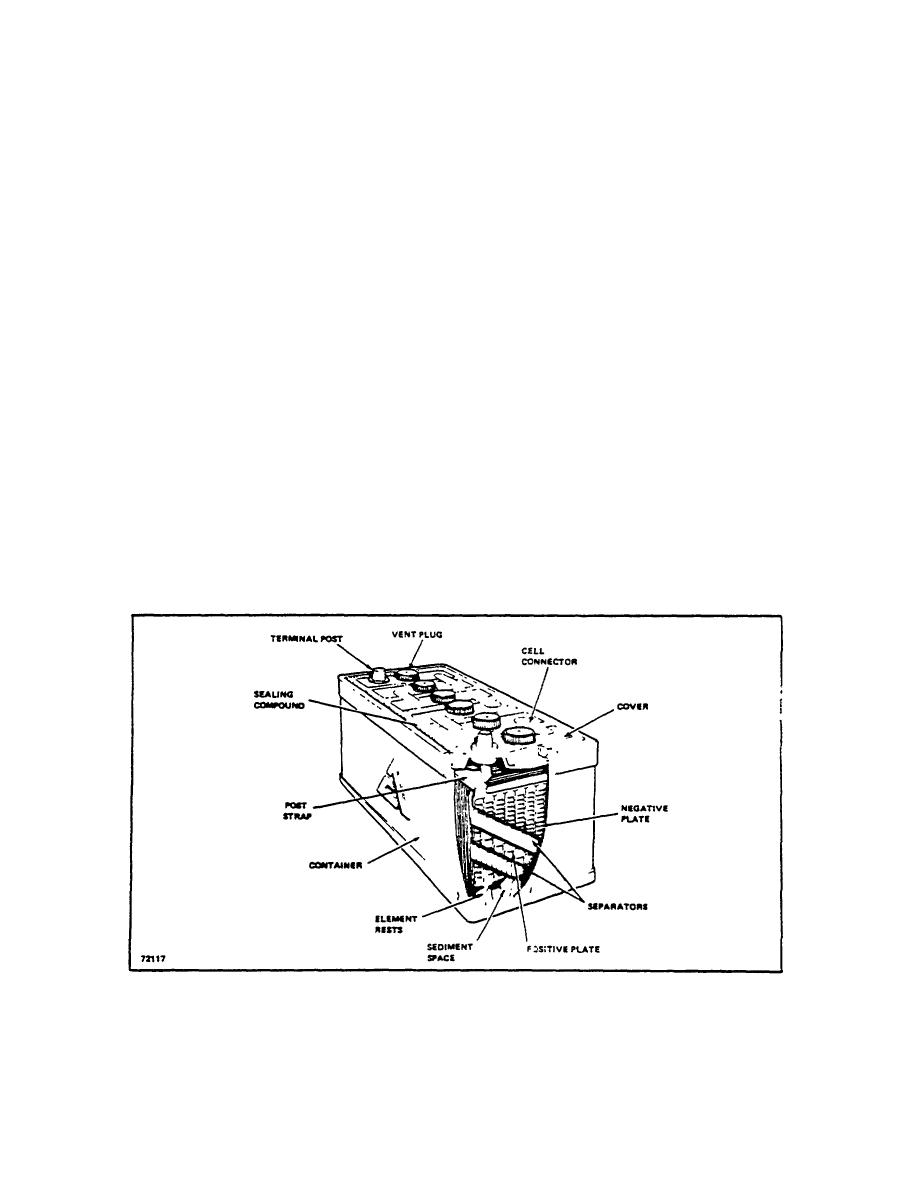

TOPIC 1. BATTERY

A. GENERAL DESCRIPTION

plates of the positive group between the plates of the

negative group, Neg. Pos. Neg., etc. The negative

The lead-acid storage battery is an electrochemical

plate group always has one or more plates than the

device for converting stored chemical energy into

positive group. Separators have one ribbed side and are

electrical energy.

assembled with the ribs vertical and facing the positive

plate. In this position, the space between the ribs allows

Active materials within the battery react chemically to

better circulation of the electrolyte to the positive plates

produce a flow of direct current whenever cranking

and forms a channel by which normally loosened

motor or other current consuming devices are connected

particles of positive active material may reach the

into the battery circuit. This current is produced by

sediment spaces in the bottom of the cell.

chemical reaction between the active materials of the

plate and the sulphuric acid of the electrolyte.

A vent cap screws into a threaded hole located in each

cell cover. The cap serves two purposes. First, it closes

The internal construction of a lead-acid battery consists

the opening in the cell cover through which electrolyte

of the combination of positive and negative plates

can be checked and water added, if necessary, and

forming a cell. The plates consist of special active

second, it provides a means for the escape of gases

materials contained in cast grids of lead-antimony alloy.

formed during charging. The visual level fill is an aid to

Charged negative plates contain sponge lead, and

proper servicing. Electrolyte level should be maintained

charged positive plates contain lead peroxide. If the

by adding distilled water to the bottom of the filler hole.

positive and negative plates contact one another, a short

This gives a margin of safety against the dangers of low-

circuit is produced and the cell fails immediately. To

level operation. Overfilling should be avoided at all

prevent a short circuit between the plates, separators

times, since it causes loss of electrolyte which will result

are used. The cell is assembled by alternating the

in premature battery failure and poor performances

Electrolyte lost by overfilling causes excessive corrosion

of cables, connections and other equipment.

Figure 1-1. Battery (Typical)

R-146-1

3-71

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |